StockSteel

316 Stainless Steel Sheet Plate | Premium Corrosion-Resistant Steel

316 Stainless Steel Sheet Plate | Premium Corrosion-Resistant Steel

Couldn't load pickup availability

Product Detail Page: 316 Stainless Steel Sheet Plate

Technical Specifications

| Category | Details | Standards |

|---|---|---|

| Thickness Range | 0.1 mm – 60 mm (Customizable) | ASTM A240, EN 10088-2 |

| Width | 1000 mm, 1219 mm, 1500 mm, 1800 mm (Trimmed/Untrimmed) | JIS G4304, GB/T 3280 |

| Length | 2000 mm, 2440 mm, 3000 mm, 6000 mm | ASME SA480 |

| Hardness (HRB) | 70–90 (Cold-Rolled), 80–95 (Hot-Rolled) | ISO 6506 |

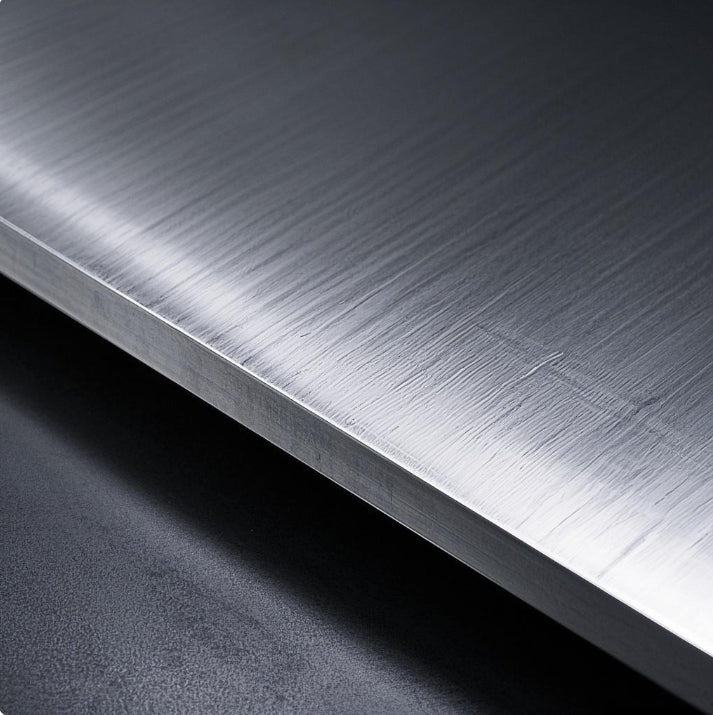

| Surface Finish | 2B, BA, No.4 (Brushed), 8K Mirror, HL (Hairline), Embossed | ASTM A480 |

| Tolerance | ±0.02 mm (Precision), ±0.1 mm (Standard) | DIN 17440 |

Mechanical & Physical Properties

| Property | Value |

|---|---|

| Density | 8.03 g/cm³ |

| Tensile Strength | ≥515 MPa (Minimum) |

| Yield Strength | ≥205 MPa |

| Elongation | ≥40% (Cold-Rolled), ≥35% (Hot-Rolled) |

| Thermal Conductivity | 16.5 W/m·K (100°C) |

| Electrical Resistivity | 7.2 × 10⁻⁷ Ω·m |

| Magnetism | Non-Magnetic (Annealed State) |

Key Features & Advantages

-

Tensile Strength: The 316 stainless steel sheet plate offers exceptional tensile strength (≥515 MPa), enabling it to withstand extreme mechanical stress in applications like chemical reactors and marine hardware.

Its high nickel (10–14%) and molybdenum (2–3%) content enhance structural integrity under dynamic loads. -

Bendability: With an elongation rate of 35–40%, this sheet stainless steel plate is ideal for forming complex shapes without cracking. Cold-rolled variants are preferred for precision components requiring tight tolerances (±0.02 mm).

-

Identification Markings: Each plate is laser-etched with SUS316 (JIS), UNS S31600 (ASTM), or 0Cr17Ni12Mo2 (GB) codes for traceability. Certifications include Mill Test Reports (MTRs) and ISO 9001 compliance.

-

Weight Calculation:

- Formula: Weight (kg) = Length (m) × Width (m) × Thickness (mm) × 8.03

- Example: A 2m × 1m × 5mm plate weighs 80.3 kg (2×1×5×8.03).

-

Corrosion Resistance: The stainless steel fine plate sheet foil excels in chloride-rich environments (e.g., seawater, chemical plants) due to its Mo-enhanced passive layer. It resists pitting, crevice corrosion, and stress corrosion cracking (SCC).

Why Does Stainless Steel Rust?

While 316 stainless steel sheet plate is highly corrosion-resistant, rust may occur under specific conditions:

- Chloride Exposure: Prolonged contact with saltwater or cleaning agents containing Cl⁻ ions can penetrate the passive layer, initiating localized pitting.

- Mechanical Damage: Scratches or abrasions from tools (e.g., steel brushes) expose the iron-rich substrate to oxidation.

- Galvanic Corrosion: Direct contact with carbon steel or copper in humid environments accelerates electrochemical degradation.

- High-Temperature Oxidation: Sustained exposure above 400°C degrades the chromium oxide layer, reducing corrosion resistance

.

Preventive measures include:

- Regular cleaning with pH-neutral detergents.

- Applying passivation treatments (e.g., nitric acid) to restore the oxide layer.

- Avoiding contact with dissimilar metals.

Why Choose Our Stainless Steel?

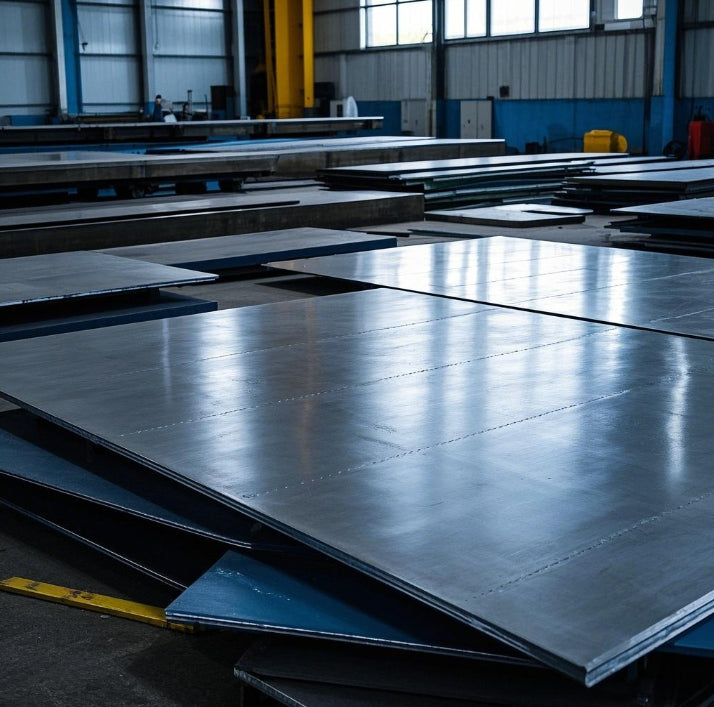

- Premium Quality: Our 316 stainless steel sheet plate is sourced from top mills (POSCO, Outokumpu, TISCO) with full traceability and compliance with ASTM/EN/JIS standards.

- Custom Solutions: Tailored dimensions (e.g., 1219×3048 mm), thicknesses (0.1–60 mm), and surface finishes (mirror, brushed) to meet niche industrial needs.

- Fast Delivery: Over 500 tons of ready stock for immediate shipment, supported by global logistics partners.

- Technical Support: Expert guidance on welding (TIG/MIG), heat treatment (1050–1150°C annealing), and fabrication.

- Sustainability: 100% recyclable material with eco-friendly production processes, certified by ISO 14001.