StockSteel

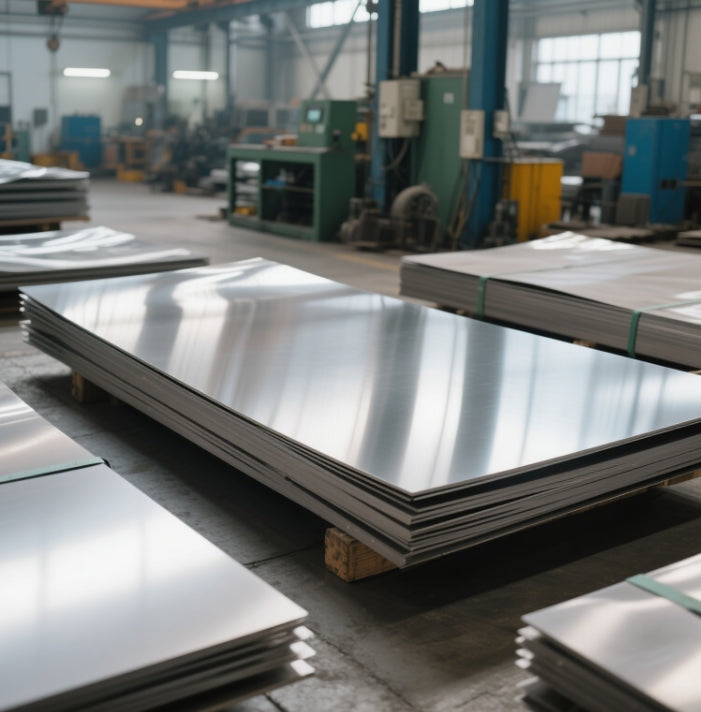

Advanced Stainless Steel Metal Plate | 06Cr19Ni10 Cold Rolled

Advanced Stainless Steel Metal Plate | 06Cr19Ni10 Cold Rolled

Regular price

$1,555.00 SGD

Regular price

Sale price

$1,555.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Advanced Stainless Steel Metal Plate | 06Cr19Ni10 Cold Rolled

Product Overview

06Cr19Ni10 (equivalent to stainless steel plate 304) is a versatile austenitic stainless steel renowned for its exceptional corrosion resistance, durability, and adaptability. Ideal for industrial and commercial applications such as stainless steel plate distributor networks, structural components, and precision parts requiring stainless steel plate gauge chart compatibility, this material meets stringent global standards like ASTM A240, EN 10088-2, and JIS SUS304.

Technical Specifications

| Category | Details |

|---|---|

| Standard | GB/T 20878-2007, ASTM A240 (S30400), EN 10088-2 (X5CrNi18-10), JIS SUS304, DIN 1.4301 |

| Chemical Composition | C ≤0.08%, Si ≤1.00%, Mn ≤2.00%, Cr 18.00–20.00%, Ni 8.00–11.00%, P ≤0.045%, S ≤0.030% |

| Hardness | ≤187 HB (Brinell), ≤90 HRB (Rockwell B), ≤200 HV (Vickers) |

| Dimensions | Thickness: 0.5–50 mm, Width: 1000–2000 mm, Length: Customizable

|

| Processing | Cold Rolled, Annealed, Pickled, No. 2B/BA Finish, Precision Slitting |

Key Properties

Tensile Strength

- ≥520 MPa: The high tensile strength ensures resistance to deformation under heavy loads, making it suitable for structural frameworks and stainless steel plate distributor components.

- Yield Strength: ≥205 MPa, providing stability in high-stress environments like chemical processing equipment and construction.

Bending Strength

- Excellent bendability (up to 180° without cracking) due to its austenitic structure, ideal for forming complex shapes such as appliance panels and HVAC ducts.

Weight Calculation

- Formula: Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93 g/cm³).

- Example: A 3 mm thick plate (1.5m × 3m) weighs 107.1 kg (3 × 1.5 × 3 × 7.93).

Identification & Marking

- Standard markings include 06Cr19Ni10 (GB), S30400 (ASTM), 1.4301 (DIN), and X5CrNi18-10 (EN).

Why Stainless Steel Rusts?

- Chloride Exposure: Prolonged contact with chlorides (e.g., seawater, de-icing salts) can cause pitting corrosion.

- Surface Contamination: Residual iron particles or organic debris may induce localized rusting. Regular cleaning with pH-neutral solutions is recommended.

- Thermal Processing: Improper welding or annealing (above 425°C) can deplete chromium content, reducing corrosion resistance.

- Intergranular Corrosion: Sensitization at 500–800°C may lead to chromium carbide formation along grain boundaries, weakening the material.

Applications

- Industrial: Chemical tanks, heat exchangers, and stainless steel plate gauge chart-compliant components.

- Architectural: Decorative panels, elevator cladding, and structural supports.

- Food & Medical: Sanitary equipment, surgical tools, and pharmaceutical machinery.

Why Choose Our Stainless Steel Plates?

- Certified Quality: Compliance with ASTM, EN, and ISO standards guarantees material consistency.

- Custom Solutions: Tailored dimensions (0.5–50 mm thickness) and finishes (2B, BA, polished) for diverse project needs.

- Global Stock Availability: Over 15,000 tons of ready-to-ship inventory for stainless steel plate distributor partners.

- Technical Expertise: Free consultation on welding (TIG/MIG), forming, and corrosion prevention.

- Sustainability: Recyclable material with low carbon footprint, aligned with eco-friendly manufacturing practices.