StockSteel

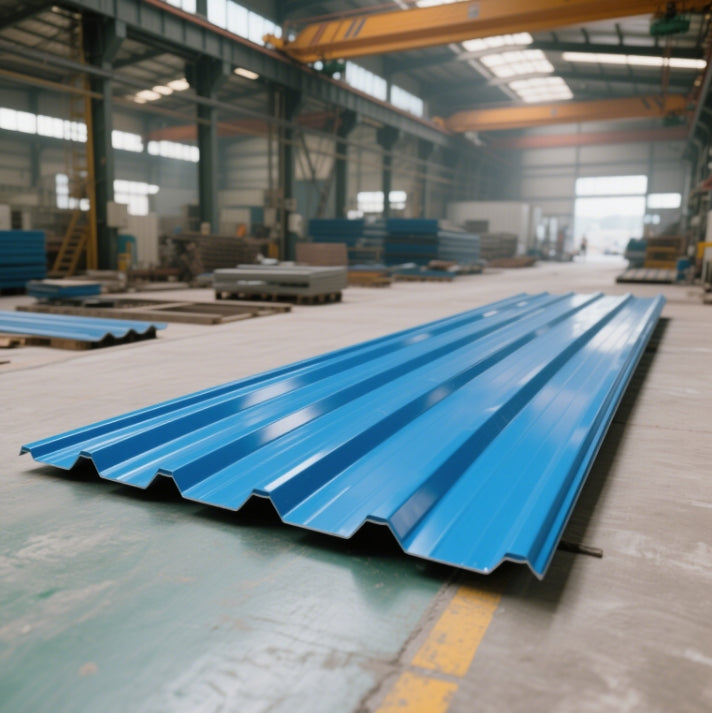

Affordable Tin Roofing Sheets | 30g/40g Zinc Coated

Affordable Tin Roofing Sheets | 30g/40g Zinc Coated

Couldn't load pickup availability

Affordable Tin Roofing Sheets | 30g/40g Zinc Coated

Premium Corrosion-Resistant Solution for Industrial & Residential Roofing

Product Specifications

| Attribute | Details |

|---|---|

| Material | Steel roofing sheets (Galvanized Steel Grade DX51D, ASTM A653/JIS G3302) |

| Zinc Coating | 30g/m² (Standard) or 40g/m² (Heavy-Duty) |

| Thickness | 0.13mm – 1.5mm (Customizable) |

| Width | 600mm – 1250mm (Pre-Corrugation) |

| Length | 1.8m – 12m (Tailored to Project Needs) |

| Surface Finish | Regular Spangle/Minimum Spangle/Zero Spangle |

| Hardness | HRB 60–95 (Soft/Medium/Full Hard Options) |

| Tensile Strength | 270–550 MPa (Grade-Dependent) |

| Certifications | ISO 9001, SGS, CE, SONCAP |

| Application | Residential Roofs, Industrial Sheds, Agricultural Buildings |

Technical Properties

Tensile Strength

Our roofing sheet metal achieves tensile strengths between 270 MPa and 550 MPa, depending on the steel grade and zinc coating thickness. This ensures structural integrity under heavy snow loads, wind pressures up to 150 km/h, and thermal expansion in temperatures ranging from -40°C to 120°C. Third-party testing validates compliance with ASTM A653 standards, guaranteeing resistance to deformation in extreme conditions.

Bending Strength

Engineered with a trapezoidal or sinusoidal corrugation profile, these steel roofing sheets exhibit exceptional bending strength, minimizing sagging over spans up to 1.2m. The corrugated design enhances load distribution, making them ideal for regions prone to cyclones or seismic activity.

Weight Calculation Formula

Calculate the approximate weight per square meter using:

Weight (kg/m²) = (Thickness in mm × 7.85) + Zinc Coating Weight (g/m²) × 0.001

For example, a 0.4mm sheet with 40g/m² zinc coating weighs 3.54 kg/m².

Identification & Marking

Each sheet is stamped with:

- Grade (e.g., DX51D+AZ)

- Zinc Coating Class (Z30/Z40)

- Batch Number for traceability

- Certification Marks (ISO, CE)

Why Galvanized Steel Resists Rust?

While roofing sheets are galvanized for corrosion resistance, improper handling or environmental factors can cause localized rust. Key considerations include:

- Zinc Sacrificial Protection: The zinc layer oxidizes preferentially, shielding the base steel.

- Coating Uniformity: Electro-galvanizing ensures a consistent 30g/40g/m² zinc layer, preventing pinhole defects.

- Environmental Exposure: Coastal areas with salt spray may require 40g/m² coatings for extended durability.

- Maintenance: Annual rinsing with pH-neutral solutions removes corrosive debris like bird droppings or industrial pollutants.

Applications

- Residential Roofing: Lightweight roofing sheets reduce structural load while providing 50+ years of service.

- Industrial Warehouses: Corrugated steel roofing sheets withstand UV radiation and chemical exposure.

- Agricultural Sheds: Ventilated designs prevent condensation, protecting livestock and stored crops.

Why Choose Our Roofing Sheets?

- Cost-Effective Durability: Zinc-coated roofing sheet metal outperforms asphalt shingles with 2x lifespan at 60% lower lifecycle costs.

- Customization: Tailored dimensions, profiles (e.g., 76mm trapezoidal waves), and colors (RAL-based pre-painted options).

- Global Compliance: Meets ASTM, JIS, and EN standards for seamless international project integration.

- Eco-Friendly: 100% recyclable material with a carbon footprint 40% lower than concrete roofing.

- 24/7 Support: Expert guidance on installation, load calculations, and corrosion prevention.