StockSteel

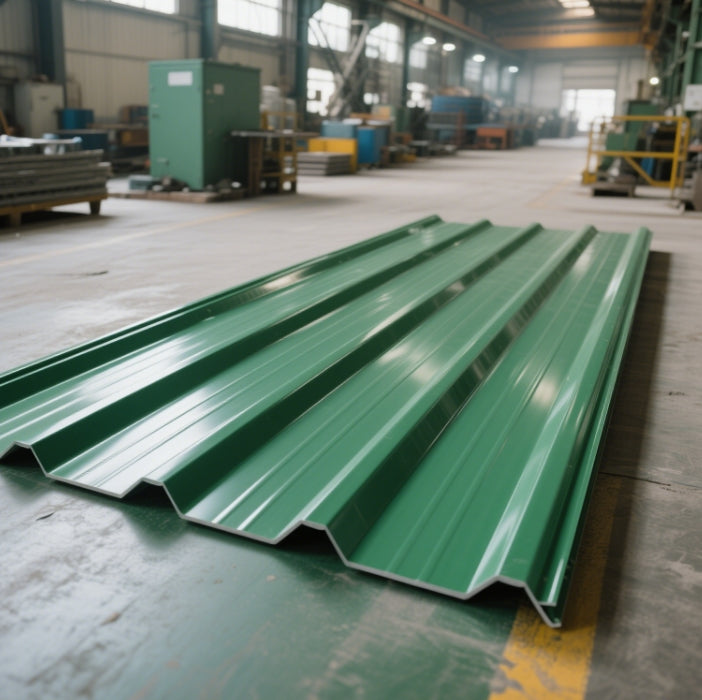

Architectural Tin Roofing Sheets | Aesthetic & Functional

Architectural Tin Roofing Sheets | Aesthetic & Functional

Couldn't load pickup availability

Architectural Tin Roofing Sheets | Aesthetic & Functional

Product Overview

Our metal sheeting roof solutions redefine modern architecture by combining timeless elegance with industrial-grade durability. Designed for residential, commercial, and heritage restoration projects, these plastic roofing sheet-compatible tin roofing sheets feature advanced prepainted finishes and corrosion-resistant coatings. Whether you prioritize aesthetics for historical preservation or structural integrity for harsh climates, our products deliver unmatched performance.

Specifications

| Parameter | Details |

|---|---|

| Material | Galvanized Steel (G90/SGCC), Aluzinc (AZ150), Prepainted TINPLATE |

| Thickness | 0.14–1.5 mm (customizable up to 6mm for heavy-duty applications) |

| Width | 600–1250 mm (adjustable to match modified bitumen roof base sheet) |

| Length | 1.8–12 meters (tailored for seamless integration) |

| Surface Finish | Stone-Coated, Anti-Glare Matte, PVDF Fluoropolymer, Embossed Patterns |

| Coating Type | Hot-Dip Galvanized (60–275 g/m²), Electrolytic Tinplate (1.1–5.6 g/m²) |

| Corrugation Profile | Trapezoidal, Roman Tile, Double V-Crimp, Custom Architectural Designs |

| Tensile Strength | 230–620 MPa (grades TS230 to TS620) |

| Hardness (HR30T) | T2 (52+3), T3 (57+3), T5 (65+3) |

| MOQ | 5 Tons (bulk discounts available) |

Key Attributes

-

Aesthetic Versatility:

- Mimic traditional clay tiles or wooden shakes with embossed stone-coated finishes.

- Customizable colors (RAL/Pantone) to complement plastic roofing sheet installations or heritage restorations.

-

Structural Excellence:

- Tensile Strength: Grades TS230–TS620 ensure resistance to heavy snow loads (1.5 kN/m²) and wind speeds up to 150 km/h.

- Bending Strength: Ribbed profiles and cold-rolled processing enhance rigidity, preventing sagging even under prolonged stress.

-

Eco-Friendly & Low Maintenance:

- Recyclable materials align with LEED standards, reducing environmental impact.

- UV-stable coatings retain color for 25+ years, minimizing repainting costs.

Technical Insights

Tensile & Bending Strength

Our metal sheeting roof products undergo ASTM/JIS-certified testing to meet global standards. The tensile strength range (230–620 MPa) accommodates seismic zones and industrial machinery loads. For bending, the trapezoidal rib design distributes stress evenly, with a safety factor of 2.5x higher than standard 3-tab shingles.

Weight Calculation

Use this formula to estimate sheet weight:

Example: A 10m × 1.2m sheet at 0.5mm thickness weighs .

Identification & Traceability

Each sheet is laser-etched with:

- Grade (e.g., TS275, AZ150)

- Coating type (Galvanized/Aluzinc/PVDF)

- Batch number for ISO 9001 compliance.

Why Stainless Steel Can Rust?

While stainless steel resists corrosion, specific conditions trigger oxidation:

- Electrochemical Corrosion: Chloride ions (e.g., coastal air, road salt) penetrate the chromium oxide layer, forming micro-galvanic cells.

- Mechanical Damage: Scratches or improper welding expose raw steel to moisture.

- High-Temperature Degradation: Prolonged exposure above 400°C weakens the oxide film.

Preventive measures: Use modified bitumen roof base sheet underlayment and pH-neutral cleaning agents.

Why Choose Our Stainless Steel Roofing?

-

Premium Material Quality:

- 18% chromium + 8–10% nickel alloy exceeds ASTM standards, ensuring 50+ years of service.

- Cold-rolled precision guarantees ±0.02mm thickness uniformity.

-

Certifications & Sustainability:

- RoHS-compliant, 100% recyclable materials with LEED credits.

- Fireproof Class A rating (EN 13501-1).

-

Custom Solutions:

- OEM/ODM services for embossed patterns, perforations, and curved profiles.

- Global logistics with 15-day lead times for urgent projects.

-

Cost Efficiency:

- Competitive plastic roofing sheet-compatible pricing starting at $4.5/sq.ft.

- Lightweight design reduces structural reinforcement costs by 30%.