StockSteel

Budget-Friendly plate stainless steel | Bulk 201/316 Elevator Grid Exports

Budget-Friendly plate stainless steel | Bulk 201/316 Elevator Grid Exports

Regular price

$1,630.00 SGD

Regular price

Sale price

$1,630.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

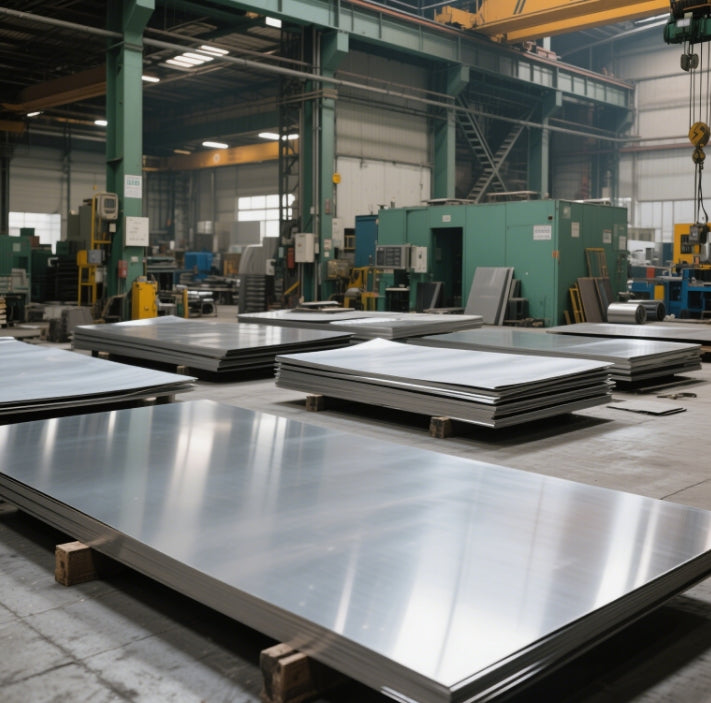

Stainless Steel Compartment Plates | Bulk 201/316 Elevator Grid Exports

Product Overview

Our stainless steel compartment plates and stainless steel diamond plate wall protection solutions are engineered for durability, corrosion resistance, and versatility. Ideal for industrial, architectural, and commercial applications, these plates combine high-performance materials with precision manufacturing. The stainless steel divided plates are available in grades 201 and 316, tailored to meet diverse environmental and mechanical demands.

Technical Specifications

| Parameter | Grade 201 | Grade 316 |

|---|---|---|

| Material Standard | ASTM A240, AISI 201 | ASTM A240, AISI 316 |

| Thickness | 0.3–6 mm (Cold Rolled) | 0.3–6 mm (Cold Rolled) |

| Width | 1000–2000 mm | 1000–2000 mm |

| Length | 2000–6000 mm | 2000–6000 mm |

| Hardness (Rockwell) | HRB 70–90 | HRB 85–95 |

| Density | 8.0 g/cm³ | 8.0 g/cm³ |

| Surface Finish | 2B, BA, HL, NO.4, Mirror | 2B, BA, HL, NO.4, Mirror |

| Yield Strength | ≥ 215 MPa | ≥ 220 MPa |

| Tensile Strength | ≥ 505 MPa | ≥ 520 MPa |

| Elongation | ≥ 40% | ≥ 40% |

Key Properties & Applications

Tensile Strength & Bendability

- Tensile Strength: Grade 201 offers 505 MPa ultimate tensile strength, while Grade 316 exceeds 520 MPa . This ensures resistance to deformation under heavy loads, making them suitable for stainless steel divided plates in structural frameworks.

- Bend Strength: Both grades exhibit excellent ductility (≥40% elongation), enabling complex forming for stainless steel diamond plate wall protection and elevator grids without cracking .

Identification & Weight Calculation

- Identification: Grades are marked per ASTM/AISI standards (e.g., "316" etched on plates). Chemical composition (e.g., 16–18% Cr in 316) further distinguishes them .

- Weight Formula:

Corrosion Resistance & Rust Prevention

- Why Stainless Steel Rusts:

- Exposure to chlorides (e.g., seawater) or sulfur compounds can degrade passive oxide layers .

- Poor surface finish or contamination during fabrication accelerates pitting .

- Prevention: Grade 316’s molybdenum content (2–3%) enhances resistance to chlorides, making it ideal for harsh environments .

Manufacturing Process

- Material Selection: Medical-grade 304/316L raw materials ensure biocompatibility and corrosion resistance .

- Precision Cutting: Laser/CNC machining achieves ±0.01 mm accuracy for stainless steel compartment plates .

- Surface Treatment: Electrolytic polishing or #4 satin finishes enhance aesthetics and durability .

- Quality Control: Third-party SGS testing validates chemical composition and mechanical properties .

Why Choose Our Stainless Steel Solutions?

- Superior Material Integrity:

- GMP-certified suppliers provide 316L/304 stainless steel with SGS reports for traceability .

- ISO 13485 & 9001 certifications guarantee compliance with medical and industrial standards .

- Customization & Flexibility:

- Low MOQ (10+ units) and rapid prototyping (48-hour drawing confirmation) .

- Modular production lines accommodate bulk orders for stainless steel diamond plate wall protection .

- Global Logistics:

- Strategic partnerships with DHL/FedEx ensure on-time delivery to 18+ countries .

- Technical Expertise:

- Over 20 years of precision metalworking experience, supported by patents in ultra-thin tube manufacturing .