StockSteel

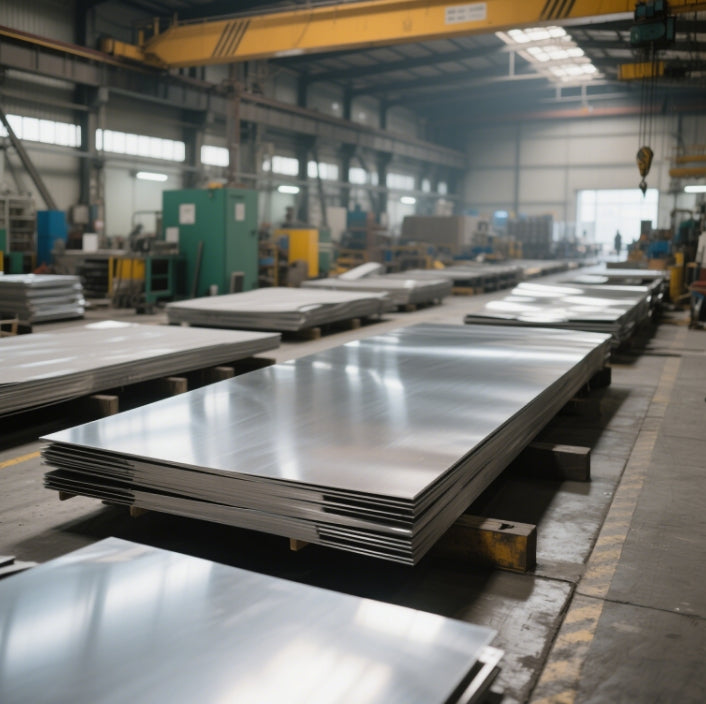

Corrosion-Proof plate stainless steel | Custom Railroad & Staircase Designs

Corrosion-Proof plate stainless steel | Custom Railroad & Staircase Designs

Couldn't load pickup availability

Corrosion-Proof Stainless Steel Plate | Custom Railroad & Staircase Designs

Product Specifications

| Parameter | Details |

|---|---|

| Material Grade | 316L / 304 Stainless Steel (AISI 316L/304, EN 1.4404/1.4301) |

| Thickness | 1.5mm – 12mm (Customizable) |

| Standard Sizes | 1000mm × 2000mm, 1220mm × 2440mm, 1500mm × 3000mm (Tailored to Order) |

| Surface Finishes | Brushed (No.4), Mirror (BA), Bead Blasted, Anti-Slip Embossed |

| Hardness (HV) | 215–250 HV (316L) / 170–200 HV (304) |

| Tensile Strength | ≥485 MPa (316L) / ≥515 MPa (304) |

| Bending Strength | 180° Cold Bending (Thickness ≤6mm) Without Cracking |

| Temperature Range | -50°C to +800°C (Short-Term Exposure) |

Technical Highlights

Tensile Strength & Bending Performance

Our corrosion-proof stainless steel plates are engineered for structural integrity. The 316L grade offers tensile strength ≥485 MPa, ideal for high-stress environments like railroad tracks and industrial staircases. For applications requiring flexibility, such as curved architectural designs, the material withstands 180° cold bending (for ≤6mm thickness) without micro-cracks. This ensures longevity even in dynamic load-bearing scenarios.

Material Identification & Marking

Each plate is laser-etched with AISI/EN codes (e.g., "316L" or "1.4404"), thickness, and batch number for traceability. Compliance with ASTM A240 and ISO 9444 guarantees chemical composition accuracy, including 16–18% chromium and 2–3% molybdenum in 316L for enhanced corrosion resistance.

Weight Calculation Formula

Calculate plate weight using:

Example: A 2m × 1m × 3mm plate weighs .

Why Stainless Steel May Rust?

While inherently corrosion-resistant, improper handling can compromise performance:

- Chloride Exposure: Prolonged contact with seawater, de-icing salts, or industrial chemicals may degrade the passive chromium oxide layer.

- Mechanical Damage: Deep scratches or abrasions expose raw metal to oxidation.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel) in conductive environments triggers electrochemical reactions.

- Contamination: Iron particles from tools or storage environments can embed into surfaces, initiating rust spots.

Applications & Versatility

-

Railroad Infrastructure

- 316L plates resist railbed moisture and chemical exposure, reducing maintenance costs.

- Custom-cut for track liners, junction plates, and corrosion-proof fasteners.

-

Architectural Staircases

- Anti-slip embossed finishes (Ra 20–50μm) ensure safety in commercial and marine settings.

- Mirror-polished variants (Ra ≤0.01μm) blend functionality with luxury aesthetics.

-

Decorative & Functional Extensions

- Ideal as base material for gold plated stainless steel jewellery, offering hypoallergenic properties and durability.

- Compatible with heavy duty stainless steel dinner plates for industrial kitchens, combining hygiene and scratch resistance.

Advanced Manufacturing Processes

- Laser Cutting: Precision ±0.1mm for intricate designs.

- Electropolishing: Enhances corrosion resistance by smoothing micro-surface imperfections.

- Passivation: Nitric acid treatment to reinforce the chromium oxide layer.

Why Choose Our Stainless Steel?

-

Superior Corrosion Resistance

- 316L’s molybdenum content resists pitting in chloride-rich environments, outperforming standard 304 grade.

-

Certified Quality

- ISO 9001, ASTM A240, and EN 10088-1 certifications ensure global compliance.

-

Customization & Scalability

- Tailor thickness (1.5–12mm), finishes, and sizes for niche projects.

- OEM support for branded is stainless steel gold plated jewelry good inquiries, with electroplating options.

-

Eco-Conscious Production

- 98% material utilization rate and RoHS-compliant processes minimize waste.

-

Lifetime Warranty

- 15-year anti-corrosion guarantee for industrial applications.