StockSteel

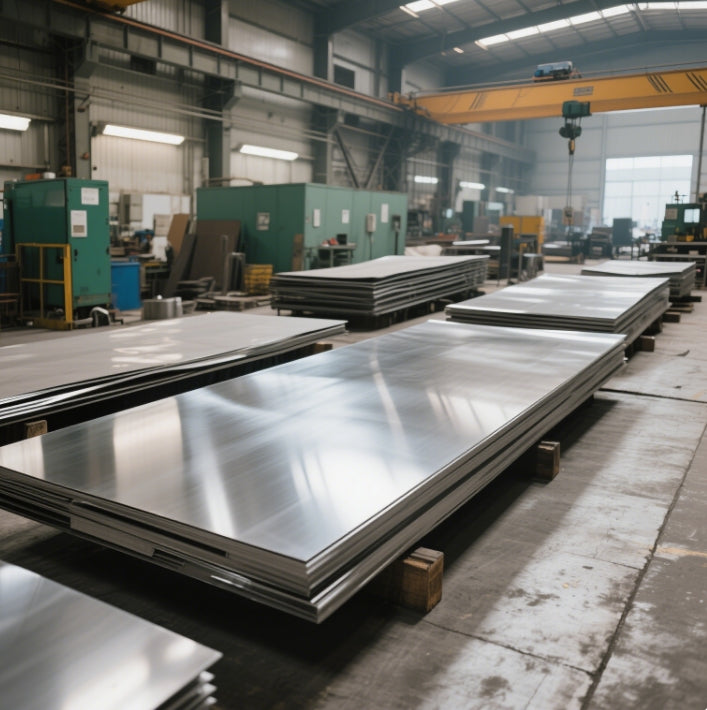

Cost-Effective Stainless Steel Metal Plate | HL Surface & 06Cr19Ni10

Cost-Effective Stainless Steel Metal Plate | HL Surface & 06Cr19Ni10

Couldn't load pickup availability

Cost-Effective Stainless Steel Metal Plate | HL Surface & 06Cr19Ni10

Product Overview

Our 06Cr19Ni10 stainless steel plates (UNS S30400) combine affordability with premium performance, ideal for architectural, industrial, and food-grade applications. Featuring a HL (Hairline) surface finish, these plates deliver a refined aesthetic while maintaining exceptional durability. Compliant with ASTM A240, JIS G4303, and GB/T 20878 standards, they are engineered for corrosion resistance, ease of fabrication, and long-term reliability.

Technical Specifications

1. Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤0.08 |

| Chromium (Cr) | 18.00–20.00 |

| Nickel (Ni) | 8.00–11.00 |

| Manganese (Mn) | ≤2.00 |

| Silicon (Si) | ≤1.00 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.030 |

Certified to ASTM A240, EN 10088-2, and ISO 3506 standards.

2. Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ≥520 MPa |

| Yield Strength (0.2% Offset) | ≥210 MPa |

| Elongation (%) | ≥40 |

| Hardness (Brinell) | ≤187 HB |

| Density | 7.93 g/cm³ |

3. Available Dimensions & Surface Finishes

| Thickness (mm) | Width (mm) | Length (mm) | Surface Finish |

|---|---|---|---|

| 1/4 in stainless steel plate (6.35 mm) | 1000–2200 | 2000–6000 | HL (Hairline), 2B, No.4, Mirror |

| 0.5–50 | 1000–2500 | Custom | Anti-Slip, Embossed, BA |

Custom edge treatments (mill edge, slit edge) and laser cutting available.

Key Features & Applications

1. HL (Hairline) Surface Finish

The HL finish creates unidirectional, continuous lines resembling fine hair strands (achieved with 150–240# abrasives), offering:

- Aesthetic Appeal: Ideal for stainless steel wall plates in modern architecture, elevator panels, and decorative interiors.

- Scratch Resistance: Enhanced surface hardness reduces wear in high-traffic areas like stainless steel kick plates for doors or machinery guards.

- Low Reflectivity: Minimizes glare, suitable for commercial signage and sanitary equipment.

2. Superior Corrosion Resistance

06Cr19Ni10 resists oxidation, pitting, and chloride-induced corrosion due to its 18% chromium content. Applications include:

- Food processing equipment (FDA/EU 10/2011 compliant).

- Coastal infrastructure and marine fixtures.

3. Formability & Weldability

- Cold/Hot Working: Easily shaped into complex geometries for industrial tanks, conveyor systems, and structural frameworks.

- Welding Compatibility: Low carbon content minimizes carbide precipitation, ensuring strong joints in 1/4 in stainless steel plate fabrications.

Performance Details

1. Weight Calculation

Calculate plate weight using:

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93)

Example: A 6.35mm (1/4") × 1.5m × 3m plate ≈ 226.3 kg.

2. Tensile & Bend Strength

- Tensile Strength: ≥520 MPa ensures structural integrity under heavy loads, perfect for stainless steel kick plates in industrial settings.

- Bend Strength: High ductility allows bending to 180° without cracking (2T bend radius).

3. Marking & Traceability

Plates are laser-etched with grade (06Cr19Ni10/S30400), thickness, heat number, and certification (EN 10204 3.1 or ASTM A480).

4. Why Stainless Steel Rusts?

Despite its corrosion resistance, rust can occur due to:

- Chloride Exposure: Prolonged contact with seawater, de-icing salts, or industrial cleaners disrupts the chromium oxide layer.

- Mechanical Damage: Scratches or abrasions expose the iron substrate to oxidation.

- Poor Maintenance: Stagnant water or organic debris accelerates localized corrosion.

- Low Oxygen Environments: Crevices or sludge buildup inhibit oxide layer regeneration.

Why Choose Our 06Cr19Ni10 Stainless Steel Plates?

- Certified Quality: ISO 9001, ISO 14001, and ISO 45001 certified production with full Mill Test Reports (MTC).

- Custom Solutions: Tailored dimensions (including 1/4 in stainless steel plate), finishes (HL, No.4, Mirror), and anti-slip textures for stainless steel kick plates or wall plates.

- Global Compliance: Meets ASTM, EN, JIS, and GB standards for international projects.

- Rapid Turnaround: 7–15 days lead time for standard orders, with cutting, bending, and polishing services.

- Cost Efficiency: Competitive pricing without compromising on durability or aesthetics.