StockSteel

Cost-Effective Stainless Steel Plate Price | ASTM 304L/316 Plates

Cost-Effective Stainless Steel Plate Price | ASTM 304L/316 Plates

Couldn't load pickup availability

Product Detail Page: Cost-Effective Stainless Steel Plate Price | ASTM 304L/316 Plates & Coils

Product Overview

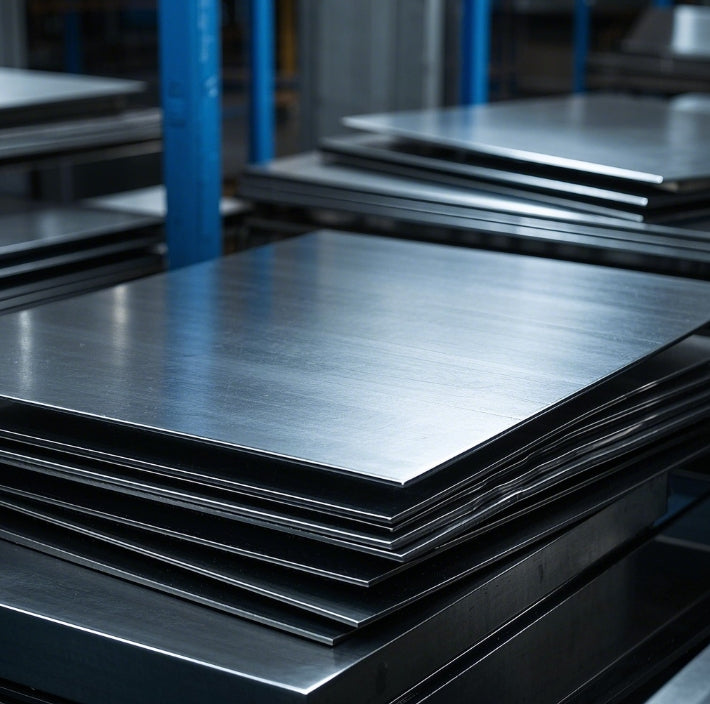

Our stainless steel plate price combines affordability with unmatched quality, offering ASTM-certified 304L/316 stainless steel plates and coils for industrial, marine, and commercial applications. Designed for durability, these plates feature cold-rolled 2B/BA finishes and customizable thicknesses (2mm–10mm), making them ideal for stainless steel plate covers in kitchens, stainless steel suction plates for machinery, and structural components in corrosive environments.

Specifications & Properties

| Parameter | 304L Stainless Steel Plate | 316 Stainless Steel Plate |

|---|---|---|

| Thickness | 0.3mm–10mm (Customizable) | 0.3mm–10mm (Customizable) |

| Width | 600mm–2000mm | 600mm–2000mm |

| Surface Finish | 2B, BA, No.4, Mirror | 2B, BA, No.4, Mirror |

| Hardness (Brinell) | ≤187 HB (Annealed) | ≤217 HB (Annealed) |

| Tensile Strength | ≥485 MPa | ≥515 MPa |

| Yield Strength | ≥170 MPa | ≥205 MPa |

| Elongation | ≥40% | ≥40% |

| Density | 7.93 g/cm³ | 8.0 g/cm³ |

| Certifications | ASTM A240, ASME SA240, EN 1.4306/1.4404 | ASTM A240, ASME SA240, EN 1.4401/1.4404 |

Mechanical & Chemical Attributes

Tensile & Bend Strength

- 304L Plates: With a tensile strength of 485 MPa, these plates resist deformation under moderate loads. Bend strength (1.5× tensile) reaches 727.5 MPa, suitable for stainless steel plate covers requiring hygienic, corrosion-resistant surfaces.

- 316 Plates: Enhanced by 2–3% molybdenum, they achieve 515 MPa tensile strength and 772.5 MPa bend strength, perfect for stainless steel suction plates in marine or chemical processing equipment.

Weight Calculation

Weight per square meter (kg/m²) = Thickness (mm) × Density (g/cm³).

Example: A 316 stainless steel plate at 5mm thickness weighs 40 kg/m² (5 × 8.0), optimizing logistics for bulk orders.

Identification Marking

Plates are laser-etched with Grade (304L/316), ASTM Standard, Heat Number, and Supplier Code for full traceability and compliance with international standards.

Why Stainless Steel Rusts? Key Causes Explained

Even premium stainless steel plates can rust under specific conditions:

- Chloride Exposure: Prolonged contact with seawater or de-icing salts triggers pitting corrosion, especially in 304L plates without molybdenum.

- Mechanical Damage: Scratches from abrasive tools disrupt the chromium oxide layer, exposing the base metal to oxidation.

- High-Temperature Oxidation: Temperatures above 800°C deplete chromium content, reducing corrosion resistance in welded areas.

- Galvanic Corrosion: Contact with carbon steel in humid environments accelerates rusting.

- Acid/Caustic Contamination: Residual chemicals (e.g., bleach) degrade passive films.

Preventive Measures:

- Use 316L plates for welded components to avoid carbide precipitation.

- Clean surfaces with pH-neutral detergents and avoid chloride-rich environments.

Applications

- Industrial: Chemical tanks, heat exchangers, and stainless steel suction plates for machinery.

- Food & Hospitality: Stainless steel plate covers, commercial kitchen countertops, and hygienic food processing equipment.

- Construction: Corrosion-resistant stainless steel plate covers for architectural cladding and marine infrastructure.

Why Choose Our Stainless Steel Plates?

- Competitive Pricing: Bulk discounts and cost-effective stainless steel plate price for 1-ton orders.

- Global Compliance: Meets ASTM, EN, JIS, and GB standards for seamless integration into international projects.

- Ready Stock: 304L/316 plates available in 2B, BA, and mirror finishes with 7–10-day delivery.

- Technical Support: Free material selection guidance and corrosion-resistance testing reports.

- Customization: Tailor thickness, width, and surface finishes to meet project-specific needs.