StockSteel

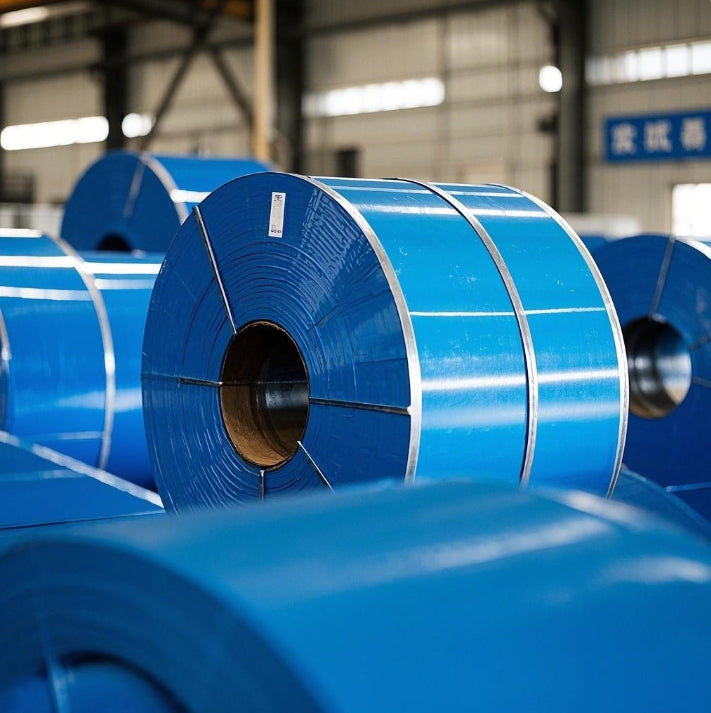

Custom Coil Coating Colors | Architectural-Grade Steel Coils

Custom Coil Coating Colors | Architectural-Grade Steel Coils

Couldn't load pickup availability

Custom Coil Coating Colors | Architectural-Grade Steel Coils

Product Overview

Our coil coating colors are designed for architects, builders, and industrial designers seeking premium durability and aesthetic versatility. Manufactured using advanced aluminized color coated galvanized coil technology, our products combine corrosion resistance with vibrant finishes, ideal for roofing, façades, automotive parts, and interior applications.

Technical Specifications

| Property | Details |

|---|---|

| Material Grade | 304/316 Stainless Steel, ASTM A240 Compliant |

| Thickness | 0.2mm–3.0mm (Customizable) |

| Width | 600mm–1500mm |

| Coating Type | PVDF, Polyester, or Epoxy-Based coil coating colors |

| Hardness (Rockwell B) | 80–95 HRB |

| Surface Finish | Matte, Glossy, Textured, or Embossed |

| Tolerance | ±0.02mm (Thickness), ±1mm (Width) |

Key Attributes

-

Tensile Strength:

Our steel coils exhibit a tensile strength range of 515–860 MPa, ensuring structural integrity under high stress. This property is critical for applications requiring resistance to deformation, such as in seismic zones or heavy-load environments. -

Bend Strength:

With a bend strength of **≥450 MPa, the material withstands repeated flexing without cracking. This makes it suitable for curved architectural elements, HVAC ducts, and automotive components. -

Weight Calculation:

Formula: Weight (kg) = Length (m) × Width (m) × Thickness (mm) × Density (7.93 g/cm³) ÷ 1000.

Example: A 1m × 1m × 1mm coil weighs approximately 7.93 kg. -

Marking Standards:

Coils are marked per ASTM A480/A480M, including grade, thickness, coating type, and batch number. Laser etching ensures permanent identification. -

Stainless Steel Rusting Causes:

While stainless steel is highly corrosion-resistant, rust may occur under extreme conditions:- Chloride Exposure: Prolonged contact with seawater or de-icing salts can degrade the passive oxide layer.

- Mechanical Damage: Scratches or abrasions expose the underlying metal to oxidation.

- Improper Cleaning: Residual iron particles from tools can trigger galvanic corrosion.

Advanced Manufacturing Process

Our china color coated galvanized steel coil undergoes a 6-stage production:

- Galvanization: Hot-dip galvanizing with zinc-aluminum alloy for base corrosion protection.

- Surface Treatment: Chromium passivation to enhance coating adhesion.

- Primer Application: Eco-friendly epoxy primer for UV resistance.

- Color Coating: High-precision PVDF or polyester coil coating colors applied via roller coating.

- Curing: Infrared oven curing at 220°C for uniform finish and hardness.

- Quality Inspection: Eddy-current testing for coating thickness consistency and defect detection.

Why Choose Our Stainless Steel Coils?

Tailored for Global Excellence

- Unmatched Durability: Chromium-rich alloy composition ensures decades of service life, even in coastal or industrial zones.

- Aesthetic Flexibility: Over 200 coil coating colors available, from metallic sheens to matte neutrals, compatible with any architectural theme.

- Eco-Conscious Production: Zero formaldehyde emissions and 100% recyclable material align with sustainable building standards.

- Cost Efficiency: Reduced maintenance and replacement costs due to anti-corrosion properties and scratch-resistant surfaces.

- Global Compliance: Meets ISO 9001, EN 10169, and LEED certification requirements.