StockSteel

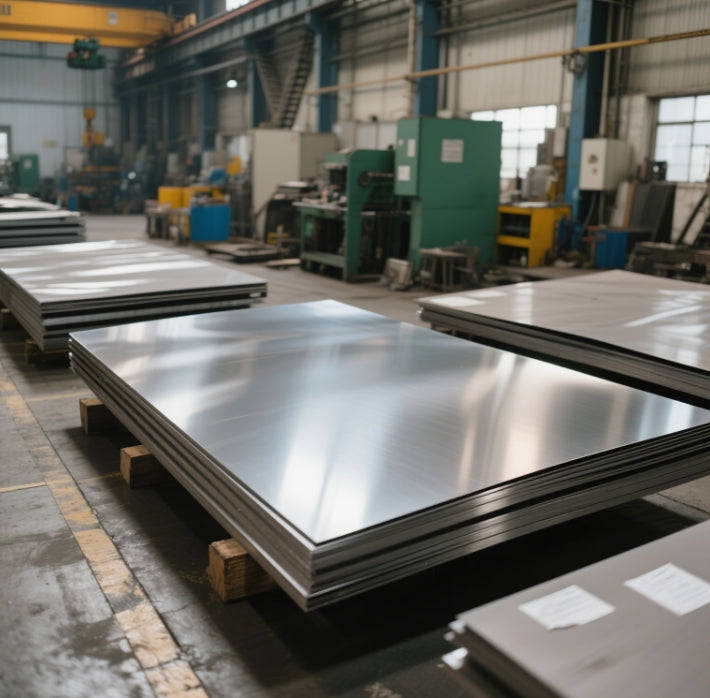

Custom-Cut plate stainless steel | 304/316 Grid Plates for Machinery Bases

Custom-Cut plate stainless steel | 304/316 Grid Plates for Machinery Bases

Couldn't load pickup availability

Custom-Cut Stainless Steel Plates | 304/316 Grid Plates for Machinery Bases

Product Specifications

| Parameter | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Hardness | ≤201 HB (Brinell) | ≤217 HB (Brinell) |

| ≤92 HRB (Rockwell B) | ≤95 HRB (Rockwell B) | |

| ≤200 HV (Vickers) | ≤200 HV (Vickers) | |

| Standard Sizes | 4'x8', 5'x10', Custom-Cut Options | 4'x8', 5'x10', Custom-Cut Options |

| Thickness Range | 0.5mm–50mm | 0.5mm–50mm |

| Key Attributes | 18% Cr, 8% Ni, High Corrosion Resistance | 16-18% Cr, 10-12% Ni, 2-3% Mo |

| Processing | Cold/Hot Rolling, Annealed Finish | Cold/Hot Rolling, Annealed Finish |

Detailed Product Features

Tensile Strength

304 Stainless Steel: Exhibits a tensile strength of 520 MPa and yield strength of 205 MPa. This ensures durability under heavy loads, making it ideal for structural components.

316 Stainless Steel: Offers slightly higher tensile strength (≥515 MPa) and superior corrosion resistance due to molybdenum content, suitable for harsh environments like marine applications.

Bend Strength

Both grades demonstrate excellent bendability. 304 stainless steel achieves a minimum bend radius of 1x thickness (annealed condition), while 316 maintains similar flexibility but with enhanced resistance to stress corrosion cracking.

Identification Standards

- ASTM/AISI: 304 (UNS S30400) and 316 (UNS S31600) .

- ISO: 1.4301 (304) and 1.4401/1.4436 (316) .

- Surface Marking: Laser-etched logos for traceability, including batch numbers and compliance certifications (e.g., ISO 9001).

Weight Calculation

Use the formula:

Example: A 1m x 2m x 3mm stainless steel plate weighs .

Why Does Stainless Steel Rust?

While stainless steel resists oxidation, improper handling can cause localized corrosion:

- Chloride Exposure: Prolonged contact with saltwater or chlorides may trigger pitting in 304; 316’s molybdenum mitigates this .

- Mechanical Damage: Scratches or weld zones without passivation reduce chromium oxide layer effectiveness .

- Thermal Stress: Overheating during fabrication can alter microstructure, increasing susceptibility .

Applications & Compatibility

- Machinery Bases: Precision-cut stainless steel plates ensure stability and vibration dampening.

- Perforated Panels: Stainless steel plate perforated designs are available for filtration, grilles, and architectural cladding.

- Supplier Flexibility: Partner with leading stainless steel plate suppliers for bulk orders or custom dimensions.

- Retail Availability: Find standard sizes at stainless steel plate Home Depot or similar outlets.

Why Choose Our Stainless Steel Plates?

- Premium Quality: Rigorous testing for hardness, tensile strength, and chemical composition compliance .

- Inventory Ready: Immediate shipping for 4x8 and 5x10 sheets, with laser/waterjet cutting services.

- Corrosion Guarantee: 316 plates include Mo-enhanced alloy for longevity in aggressive environments.

- Certifications: ASTM, ISO, and RoHS certifications ensure global acceptability.