StockSteel

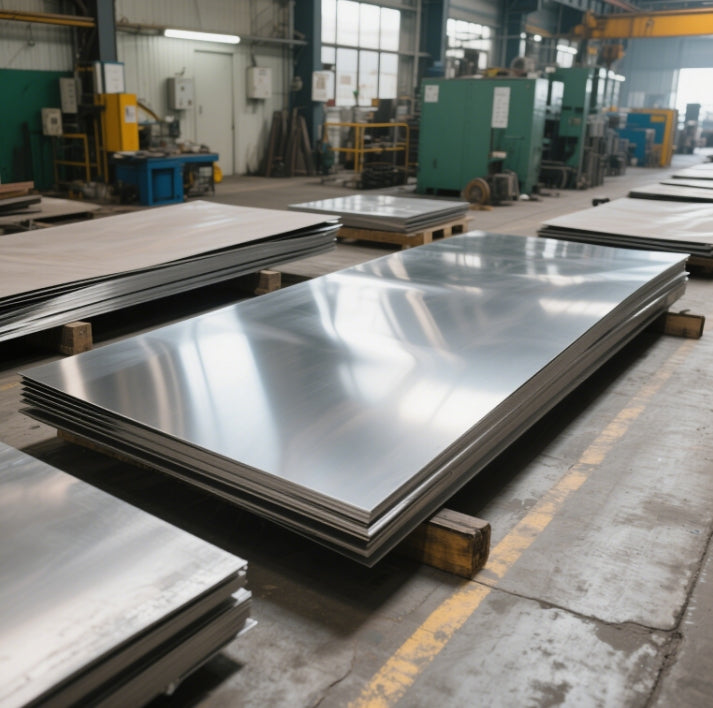

Custom-Textured plate stainless steel | Non-Slip Elevator & Staircase Surfaces

Custom-Textured plate stainless steel | Non-Slip Elevator & Staircase Surfaces

Couldn't load pickup availability

Custom-Textured Plate Stainless Steel | Non-Slip Elevator & Staircase Surfaces

Product Specifications

| Parameter | Details |

|---|---|

| Material | Stainless Steel (Grade 304/316, AISI standards compliant) |

| Thickness | 1.5 mm – 6.0 mm (Customizable) |

| Width | 1000 mm – 1500 mm |

| Length | 2000 mm – 6000 mm |

| Surface Finish | Yellow Ion Plated Stainless Steel / Embossed / Brushed / Mirror Polish |

| Hardness | HRB 70-95 (Rockwell B Scale) / HV 150-280 (Vickers) |

| Tensile Strength | 515 MPa (304) – 620 MPa (316) |

| Yield Strength | 205 MPa (304) – 290 MPa (316) |

| Weight Calculation | Formula: |

Key Attributes

-

Anti-Slip Texture

- Precision-engineered surface patterns (diamond, linear, or custom designs) for enhanced traction, ideal for elevators, staircases, and industrial walkways.

- Meets OSHA and ADA safety standards for slip resistance.

-

Corrosion Resistance

- Superior performance in humid, saline, or chemically aggressive environments due to chromium-rich oxide layer .

-

Durability

- Withstands heavy foot traffic, impact, and abrasion without deformation.

-

Aesthetic Flexibility

- Available in yellow ion plated stainless steel for a golden hue, or classic brushed/mirror finishes.

Production Process

| Stage | Description |

|---|---|

| Material Selection | High-quality stainless steel plates for sale (Grade 304/316) sourced from certified mills. |

| Laser Cutting | CNC precision cutting to ensure dimensional accuracy. |

| Texture Embossing | Hydraulic pressing to create anti-slip patterns (depth: 0.2–1.5 mm). |

| Surface Treatment | Electroplating (yellow ion plated stainless steel) or passivation for enhanced corrosion resistance. |

| Quality Inspection | Ultrasonic testing for internal defects + hardness verification . |

Technical Explanations

1. Tensile Strength & Bendability

Stainless steel plates set exhibit exceptional tensile strength (515–620 MPa), enabling them to resist fracture under tension. For bending, Grade 304/316 maintains ductility even at cold-working stages, achieving bend angles up to 180° without cracking .

2. Identification & Marking

- ASTM/AISI Standards: Plates are laser-marked with grade (e.g., 304, 316), thickness, and batch number.

- Unified Numbering System (UNS): S30408 (304) / S31600 (316) for traceability .

3. Weight Calculation

Weight is derived from density () and dimensions. Example:

.

4. Why Stainless Steel Can Rust?

Despite inherent corrosion resistance, improper maintenance or exposure to chloride-rich environments (e.g., coastal areas) may cause pitting. Contamination by carbon steel tools or prolonged contact with acidic substances can also degrade the passive layer .

Why Choose Our Stainless Steel Plates?

- Certified Quality

- Compliance with ASTM A240, EN 10088, and ISO 3506 standards.

- Custom Solutions

- Tailored dimensions, textures, and finishes (including yellow ion plated stainless steel).

- Extended Lifespan

- Optimized hardness (HRB 70-95) and wear resistance ensure decades of service .

- Global Logistics

- Efficient shipping for stainless steel plates for sale to 50+ countries.

- Technical Support

- Free consultation on installation, maintenance, and corrosion prevention.