StockSteel

Customizable Stainless Steel Metal Plate | 304L & 2B Finish Options

Customizable Stainless Steel Metal Plate | 304L & 2B Finish Options

Couldn't load pickup availability

Customizable Stainless Steel Metal Plate | 304L & 2B Finish Options

Product Overview

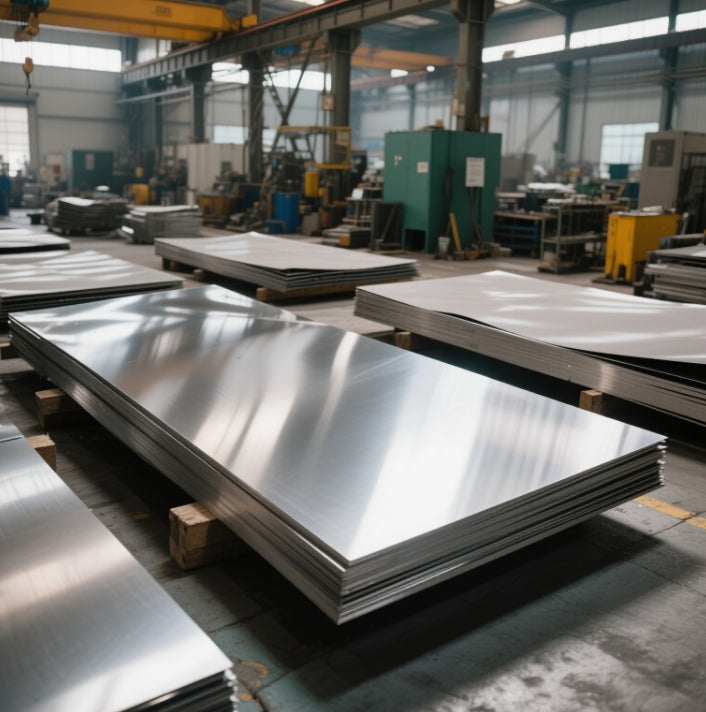

Our 304L stainless steel metal plates (UNS S30403) are engineered for versatility and durability, combining exceptional corrosion resistance with superior formability. Featuring a 2B finish — a smooth, lightly cold-rolled surface — these plates comply with ASTM A240, EN 1.4307, and GB 4806.9-2023 standards, making them ideal for food processing, architectural cladding, and industrial equipment. Customizable dimensions, surface treatments, and fabrication services ensure precision for applications like stainless steel deck plates or license plate frames stainless steel.

Technical Specifications

1. Chemical Composition

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤0.030 |

| Chromium (Cr) | 18.00–20.00 |

| Nickel (Ni) | 8.00–12.00 |

| Manganese (Mn) | ≤2.00 |

| Silicon (Si) | ≤1.00 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.030 |

Certified to ASTM A240, ISO 3506, and GB/T 4237 standards.

2. Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 485–620 MPa |

| Yield Strength (0.2% Offset) | ≥170 MPa |

| Elongation (%) | ≥40 |

| Hardness (Brinell) | ≤187 HB |

| Density | 7.93 g/cm³ |

3. Physical Properties

| Property | Value |

|---|---|

| Melting Point | 1400–1450°C |

| Thermal Conductivity | 16.2 W/m·K |

| Electrical Resistivity | 0.72 Ω·mm²/m |

| Coefficient of Thermal Expansion | 17.3 × 10⁻⁶/K (20–100°C) |

4. Available Dimensions & Surface Finishes

| Thickness (mm) | Width (mm) | Length (mm) | Surface Finish |

|---|---|---|---|

| 0.5–100 | 1000–2500 | 2000–6000 | 2B Finish, BA, No.4, HL, Mirror |

| Custom | 100–2500 | Custom | Embossed, Stainless Steel Deck Plate Textures |

Custom edge treatments (slit, mill) and laser/plasma cutting available.

Key Features & Applications

1. 2B Finish Excellence

The 2B finish — achieved through cold rolling, heat treatment, and pickling — offers:

- Hygienic Surface: Non-porous and easy to clean, perfect for stainless steel metal plates in food processing equipment.

- Aesthetic Uniformity: Subtle matte appearance ideal for license plate frames stainless steel and architectural panels.

- Cost Efficiency: Combines affordability with performance for industrial flooring and machinery guards.

2. Corrosion Resistance

304L’s low carbon content minimizes carbide precipitation during welding, resisting pitting and crevice corrosion in:

- Marine environments (coastal railings, ship components).

- Chemical processing tanks and pipelines.

3. Formability & Weldability

- Cold/Hot Working: Easily shaped into complex geometries for stainless steel deck plates or structural frameworks.

- Welding Compatibility: Suitable for TIG, MIG, and resistance welding without post-weld heat treatment.

Performance Details

1. Tensile & Bend Strength

- Tensile Strength: 485–620 MPa ensures structural integrity under heavy loads, critical for industrial platforms and conveyor systems.

- Bend Strength: Achieves 180° bends at 1T radius without cracking, ideal for custom license plate frames stainless steel.

2. Weight Calculation

Calculate plate weight using:

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93)

Example: A 6mm × 1.2m × 2.4m plate ≈ 137 kg.

3. Marking & Traceability

Plates are laser-etched with grade (304L/UNS S30403), thickness, heat number, and certification (EN 10204 3.1 or ASTM A480).

4. Why Stainless Steel Rusts?

Despite its corrosion resistance, rust can occur due to:

- Chloride Exposure: Prolonged contact with seawater, de-icing salts, or industrial cleaners disrupts the chromium oxide layer.

- Mechanical Damage: Scratches from tools or abrasives expose the iron substrate to oxidation.

- Low Oxygen Environments: Stagnant water or organic debris in crevices inhibits oxide layer regeneration.

- Chemical Contamination: Strong acids (e.g., hydrochloric acid) or alkalis accelerate localized corrosion.

Why Choose Our 304L Stainless Steel Plates?

- Certified Quality: ISO 9001, ISO 14001, and ISO 45001 certified production with full Mill Test Reports (MTC).

- Custom Solutions: Tailored dimensions, stainless steel deck plate textures, and precision cutting for license plate frames stainless steel.

- Global Compliance: Meets ASTM, EN, JIS, and GB standards for international projects.

- Rapid Turnaround: 7–15 days lead time for standard orders, with polishing, embossing, and edge treatments.

- Cost Efficiency: Competitive pricing without compromising durability or surface finish quality.