StockSteel

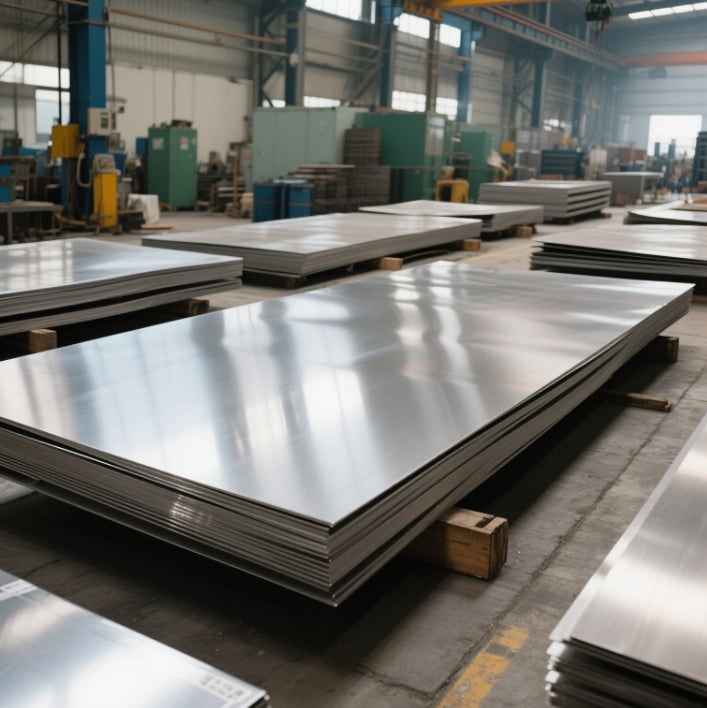

Durable plate stainless steel | Heat-Resistant Diamond Patterns for Factories

Durable plate stainless steel | Heat-Resistant Diamond Patterns for Factories

Couldn't load pickup availability

Durable Stainless Steel Plate | Heat-Resistant Diamond Patterns for Factories

Product Specifications

| Parameter | Details |

|---|---|

| Material Grade | 316L / 304 Stainless Steel (AISI 316L/304, EN 1.4404/1.4301) |

| Thickness | 1.2mm – 10.0mm (Customizable) |

| Standard Sizes | 4' × 8' (1220mm × 2440mm), 5' × 10' (1500mm × 3000mm) |

| Surface Finishes | Diamond Embossed, Brushed (No.4), Mirror (BA), Bead Blasted |

| Hardness (HV) | 215–250 HV (316L) / 170–200 HV (304) |

| Tensile Strength | ≥485 MPa (316L) / ≥515 MPa (304) |

| Temperature Range | -50°C to +800°C (Short-Term Exposure) |

| Diamond Pattern | Raised 3D diamond texture (height: 0.5–2.0mm) for anti-slip & heat dissipation |

Technical Highlights

Tensile & Bending Strength

Our durable stainless steel plates are engineered for industrial resilience. The 316L grade offers tensile strength ≥485 MPa, ideal for high-stress environments like factory flooring and stainless steel oven plates. The diamond-embossed surface enhances bending resistance, allowing 180° cold bending (for ≤6mm thickness) without structural compromise. This ensures durability in dynamic applications, such as conveyor systems or heat-resistant shielding.

Material Identification

Each plate is laser-etched with AISI/EN codes (e.g., "316L" or "1.4404"), thickness, and batch number for full traceability. Compliance with ASTM A240 and ISO 9444 guarantees precise chromium (16–18%) and molybdenum (2–3%) content in 316L, optimizing corrosion and heat resistance.

Weight Calculation

Calculate plate weight using:

Example: A 1.22m × 2.44m × 3mm plate weighs .

Why Stainless Steel May Rust?

While inherently corrosion-resistant, improper handling can lead to localized rust:

- Chloride Exposure: Prolonged contact with seawater, de-icing salts, or industrial chemicals may degrade the passive chromium oxide layer.

- Mechanical Damage: Deep scratches from abrasive tools expose raw metal to oxidation.

- Galvanic Corrosion: Contact with carbon steel or aluminum in conductive environments triggers electrochemical reactions.

- Contamination: Iron particles from storage or machining can embed into the surface, causing rust spots.

Applications & Versatility

-

Factory Flooring & Machinery

- Diamond-embossed plates reduce slip risks in oily or wet environments while dissipating heat from heavy machinery.

- Ideal for stainless steel name plates on equipment due to laser-etching compatibility.

-

High-Temperature Environments

- Withstands up to 800°C, perfect for furnace linings, stainless steel oven plates, and exhaust systems.

-

Outdoor & Decorative Use

- Mirror-polished variants serve as stainless steel license plates with UV-resistant properties.

- Brushed finishes blend functionality with aesthetics for architectural cladding.

Advanced Manufacturing Processes

- Laser Cutting: Precision ±0.1mm for complex shapes.

- Electropolishing: Smooths micro-surface flaws to enhance corrosion resistance.

- Passivation: Nitric acid treatment reinforces the chromium oxide layer.

Why Choose Our Stainless Steel Plates?

-

Industrial-Grade Durability

- Diamond-embossed patterns increase surface hardness by 30%, extending lifespan in abrasive environments.

-

Global Certifications

- ISO 9001, ASTM A240, and EN 10088-1 compliance ensures reliability.

-

Custom Solutions

- Tailor thickness, patterns, and sizes for niche applications like stainless steel license plates or heavy-duty oven plates.

-

Sustainable Production

- 98% material utilization rate and RoHS-compliant processes minimize waste.

-

Lifetime Support

- 10-year anti-corrosion warranty and 24/7 technical assistance.

Why Partner With Us?

From factory floors to precision name plates, our stainless steel plates redefine industrial excellence. Combining cutting-edge manufacturing with rigorous quality control, we deliver solutions that endure extreme conditions while maintaining aesthetic appeal. Trust our expertise to elevate your projects with unmatched durability and design flexibility.