StockSteel

Durable Stainless Steel Angles Supplier | Custom 310 Alloy Bar

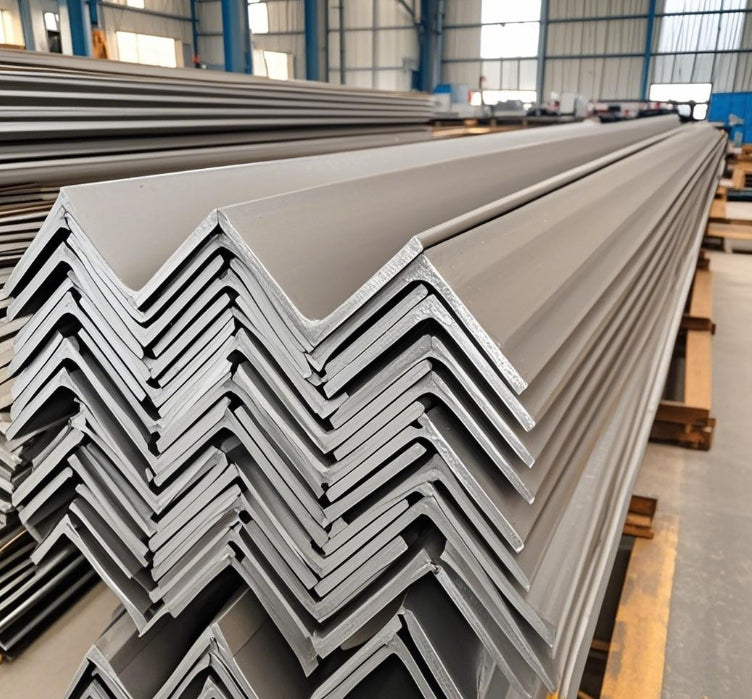

Durable Stainless Steel Angles Supplier | Custom 310 Alloy Bar

Couldn't load pickup availability

Product Detail Page: Durable Stainless Steel Angles Supplier | Custom 310 Alloy Bar

Technical Specifications & Properties

Structured for Industrial Excellence

| Category | Details |

|---|---|

| Material Grade | 310 Stainless Steel (25% Chromium, 20% Nickel) |

| Hardness | 85 HRB (Rockwell B Scale) |

| Standard Sizes | Polished stainless steel angle: 20×20mm to 150×150mm; Stainless steel slotted angle: Custom widths up to 200mm |

| Thickness Range | 1.5mm – 12mm |

| Surface Finish | Mirror polished stainless steel angle, brushed, or mill-finish (slotted options available) |

| Tolerance | ±0.5mm (width), ±0.2mm (thickness) |

| Process | Hot-rolled, precision laser-cut slotted edges, stress-relieved annealing |

Mechanical & Structural Performance

Tensile Strength

Our stainless steel angles in Grade 310 exhibit exceptional tensile strength of 620 MPa minimum, ensuring structural integrity under heavy loads. This property makes them ideal for high-temperature environments (up to 1150°C) such as furnace components or exhaust systems. The alloy’s chromium-nickel composition enhances oxidation resistance, reducing deformation risks in industrial settings.

Bend Strength

With a bend strength-to-thickness ratio of 1.5:1, these angles maintain shape stability even after repeated stress. For stainless steel slotted angle variants, laser-cut slots are strategically placed to avoid weakening load-bearing sections while enabling modular assembly in shelving or machinery frames.

Identification & Weight Calculation

Marking System

Each stainless steel angle is stamped with:

- Grade (e.g., 310)

- Dimensions (e.g., 50×50×6mm for equal legs)

- Batch Code (traceable to raw material origins and heat treatment records)

Weight Formula

Weight (kg/m) = [(Leg Width (mm) × Thickness (mm) × 2) – Thickness (mm)²] × 0.00793

Example: A 40×40×5mm polished stainless steel angle weighs ≈2.42 kg/m.

Why Stainless Steel Can Corrode?

While stainless steel angles resist rust due to chromium’s passive oxide layer, specific conditions may trigger corrosion:

- Chloride Exposure: Coastal or de-icing salt environments can penetrate the protective layer.

- Mechanical Damage: Scratches or improper handling during stainless steel slotted angle installation expose raw metal.

- Galvanic Corrosion: Direct contact with carbon steel in humid settings accelerates deterioration.

- High-Temperature Oxidation: Prolonged use above 1150°C degrades the alloy’s stability.

Preventative measures include:

- Regular cleaning of polished stainless steel angle surfaces with pH-neutral agents.

- Using isolation pads between dissimilar metals.

Applications of Stainless Steel Angles

- Construction: Reinforcing wall corners and joints in ceramic cladding systems.

- Industrial: Framing for machinery, conveyor belts, and high-temperature reactors.

- Commercial: Decorative polished stainless steel angle trims in modern architecture.

- Storage: Stainless steel slotted angle racks for warehouses with adjustable shelving.

Why Choose Our Stainless Steel Angles?

- Custom 310 Alloy Expertise: Tailored solutions for extreme environments, backed by 15+ years of metallurgical engineering.

- Precision Manufacturing: Laser-cut stainless steel slotted angle with ±0.2mm accuracy for seamless assembly.

- Aesthetic Versatility: Mirror polished stainless steel angle finishes meet both structural and design demands.

- Certified Quality: ISO 9001:2025 and ASTM A484 compliance, with third-party lab test reports.

- Global Logistics: Bulk orders shipped within 7–14 days, backed by damage-free packaging guarantees.