StockSteel

Eco-Friendly galvanized pipe fittings | Recyclable Zinc-Aluminum Coatings

Eco-Friendly galvanized pipe fittings | Recyclable Zinc-Aluminum Coatings

Couldn't load pickup availability

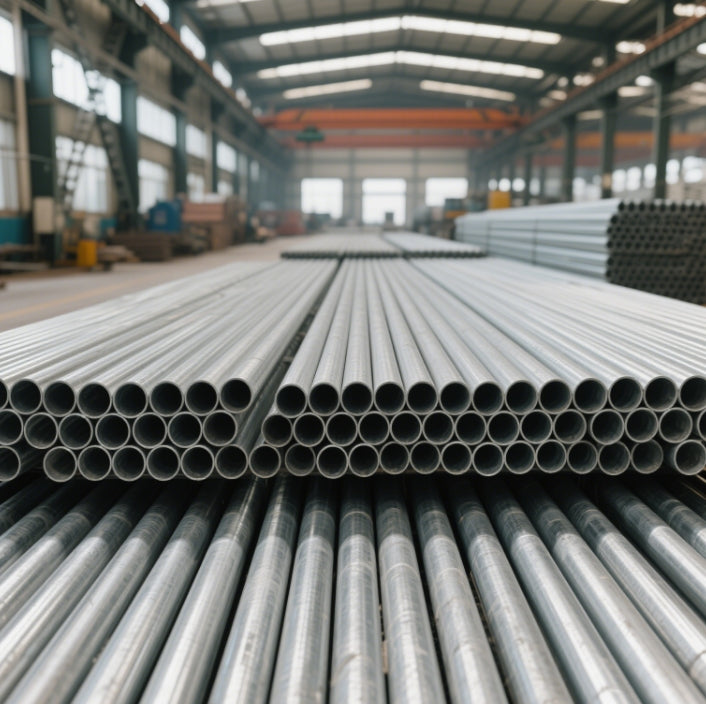

Eco-Friendly Galvanized Pipe Fittings | Recyclable Zinc-Aluminum Coatings

Product Overview

Our eco-friendly galvanized pipe fittings combine durability with sustainability, featuring recyclable zinc-aluminum coatings that reduce environmental impact while ensuring superior corrosion resistance. Designed for industrial, construction, and plumbing applications, these fittings meet global standards for performance and environmental responsibility.

Technical Specifications

| Property | Details |

|---|---|

| Material | High-grade carbon steel with zinc-aluminum alloy coating (ZnAl23Mg3Si0.4) |

| Coating Thickness | 80–120 microns (hot-dip galvanized) |

| Hardness | 200–250 HV (Vickers hardness) |

| Tensile Strength | 380–450 MPa |

| Bending Strength | ≥300 MPa |

| Diameter Range | ½" to 6" (15–168 mm) |

| Length | 5–12 meters (customizable) |

| Temperature Resistance | -20°C to 120°C |

| Certifications | ASTM A53, ASTM A106, ISO 9001, GRS (Global Recycled Standard) |

Key Features

-

Anti-Corrosion Performance:

The alloy’s biphasic structure enhances durability in corrosive soils and marine environments.

The zinc-aluminum coating forms a robust barrier against moisture and chemicals, significantly reducing galvanized pipe rust.

-

Recyclability:

Coating materials are 100% recyclable without quality loss, aligning with circular economy principles. -

Eco-Friendly Manufacturing:

Production processes minimize CO₂ emissions and adhere to Life Cycle Assessment (LCA) guidelines. -

Sharkbite Compatibility:

Compatible with galvanized pipe sharkbite fittings for quick, solder-free installation. Note: Post-weld areas require anti-corrosion treatment to maintain integrity.

Performance Details

Tensile Strength

Our fittings achieve 380–450 MPa tensile strength, ensuring structural integrity under high-pressure conditions. This is achieved through controlled hot-dip galvanizing processes, where steel reacts with molten zinc-aluminum to form a metallurgical bond.

Bending Strength

With a minimum bending strength of 300 MPa, the fittings withstand mechanical stress without deformation. The coating’s ductility prevents cracking during installation or seismic activity.

Weight Calculation

Calculate pipe weight using the formula:

Where OD = outer diameter (mm), WT = wall thickness (mm).

Identification Method

Fittings are laser-marked with:

- ASTM/ISO certification codes.

- Batch numbers for traceability.

- Coating thickness (e.g., 80g/m² for standard use, 200g/m² for high-corrosion environments).

Why Stainless Steel Resists Rust

Stainless steel’s corrosion resistance stems from a chromium-rich oxide layer that self-repairs when damaged. However, galvanized pipe rust can occur if:

- Coating Damage: Scratches or welding expose the base metal to oxygen.

- Chemical Exposure: Acids or chlorides degrade the zinc layer.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., copper) accelerates oxidation.

Our zinc-aluminum coatings mitigate these risks through superior adhesion and sacrificial protection.

Why Choose Our Stainless Steel Products?

- Certified Quality: Compliant with ASTM, ISO, and GRS standards.

- Custom Solutions: Tailored dimensions, coatings, and packaging.

- Sustainability: 80% recycled content and low-carbon production.

- Supplier Reliability: As leading galvanized pipe suppliers, we offer:

- 24/7 technical support.

- 15-day delivery guarantee.

- Lifetime corrosion warranty.