StockSteel

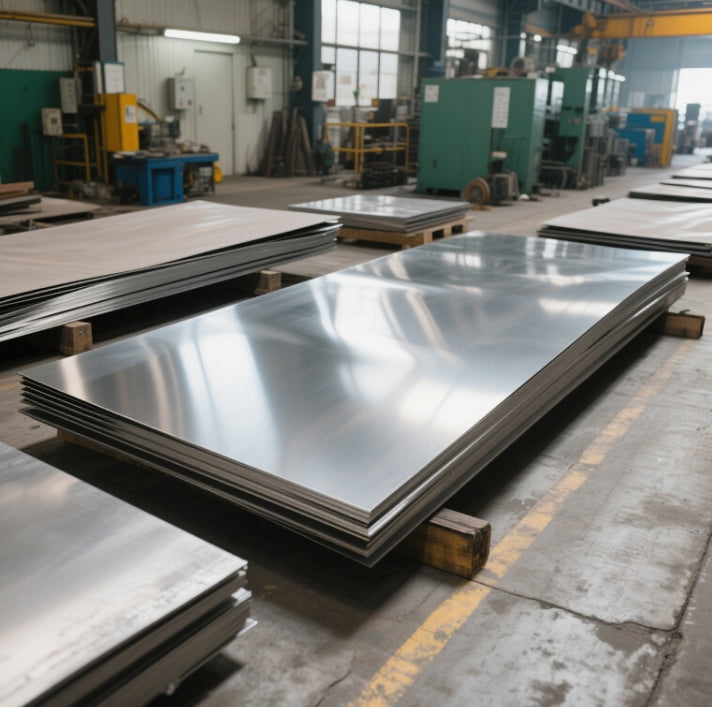

Eco-Safe plate stainless steel | Recyclable Railroad Tie & Grid Systems

Eco-Safe plate stainless steel | Recyclable Railroad Tie & Grid Systems

Regular price

$1,580.00 SGD

Regular price

Sale price

$1,580.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Eco-Safe Stainless Steel Plate | Recyclable Railroad Tie & Grid Systems

Product Specifications

| Property | Details |

|---|---|

| Material Grade | 1 2 stainless steel plate, 301 stainless steel plate, 022Cr23Ni5Mo3N (S22053) |

| Thickness | 1.0–50 mm (customizable) |

| Width | 1000–2000 mm |

| Length | 2000–6000 mm |

| Surface Finish | 2B (cold-rolled, bright annealed), No.4 (brushed), or custom |

| Standard | GB/T 4237-2007, ASTM A240, NB/T 20007 series |

Mechanical Properties & Hardness

| Property | Value Range | Test Method |

|---|---|---|

| Hardness (Rockwell) | HRB 85–100 | ASTM E18 |

| Hardness (Brinell) | 150–300 HB | ISO 6506 |

| Tensile Strength | ≥620 N/mm² | ASTM E8 |

| Yield Strength | ≥450 N/mm² | ASTM E8 |

| Elongation | ≥25% | ASTM E8 |

Dimensions & Tolerances

| Parameter | Tolerance (±) |

|---|---|

| Thickness (1–10 mm) | 0.1 mm |

| Width | 5 mm |

| Length | 10 mm |

| Flatness | ≤1.5 mm/m |

Key Attributes

- Corrosion Resistance: Superior performance in chloride-rich environments (e.g., coastal areas) due to duplex microstructure (austenite + ferrite).

- Durability: High resistance to pitting, crevice corrosion, and stress corrosion cracking (SCC).

- Recyclability: 100% recyclable, aligning with circular economy principles.

- Surface Options: Zinc plated vs galvanized vs stainless steel coatings available for enhanced protection.

Manufacturing Process

- Solution Treatment: Heated to 950–1200°C followed by rapid cooling to optimize microstructure.

- Cold Rolling: Precision-controlled to achieve uniform thickness and surface finish.

- Quality Inspection: Ultrasonic testing (UT) and eddy current testing (ECT) ensure defect-free plates.

Technical Explanations

Tensile Strength

The tensile strength of Eco-Safe stainless steel (≥620 N/mm²) exceeds industry standards, ensuring structural integrity under heavy loads. This property is critical for railroad ties and grids subjected to dynamic stresses.

Bending Strength

With a yield strength of ≥450 N/mm², the plates resist permanent deformation under bending forces. The duplex structure enhances toughness, making them ideal for curved or welded components.

Identification & Marking

Plates are laser-marked with:

- Grade (e.g., 301 stainless steel plate, S22053)

- Heat number

- Thickness and dimensions

Compliance with NB/T 20007 and GB/T 4237 ensures traceability.

Weight Calculation

Use the formula:

Stainless Steel Corrosion Causes

Despite high corrosion resistance, localized rusting may occur due to:

- Chloride Exposure: Prolonged contact with seawater or de-icing salts.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel).

- Surface Contamination: Iron particles or grease during fabrication.

Regular cleaning and passivation mitigate these risks.

Why Choose Our Stainless Steel?

- Advanced R&D: Collaboration with universities and institutes ensures cutting-edge metallurgy.

- Quality Assurance: Produced in ISO-certified facilities (e.g., VAMA, a global leader in steel technology).

- Sustainability: Recyclable material with low carbon footprint.

- Custom Solutions: Tailored dimensions, coatings (zinc plated vs galvanized vs stainless steel), and finishes.

- Global Standards: Compliance with ASTM, GB, and NB/T specifications.