StockSteel

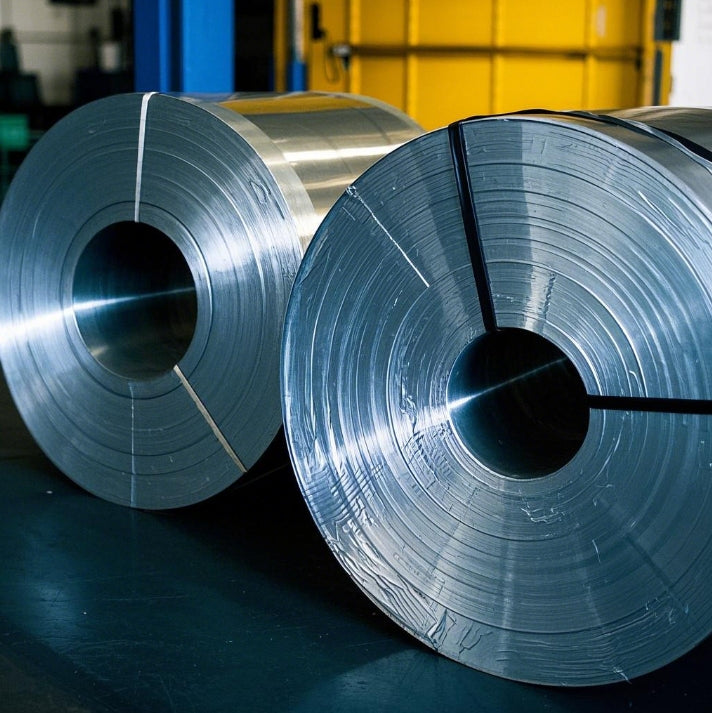

Exclusive Galvanized Steel Coils | Heavy-Duty Anti-Rust Construction

Exclusive Galvanized Steel Coils | Heavy-Duty Anti-Rust Construction

Couldn't load pickup availability

Exclusive Galvanized Steel Coils | Heavy-Duty Anti-Rust Construction

Product Overview

Our galvanized steel coils are engineered for superior corrosion resistance and structural durability, specifically tailored for heavy-duty construction projects. Manufactured by leading galvanized steel coil manufacturers, these coils combine a hot-dipped galvanized coating with advanced anti-rust treatments, ensuring longevity in harsh environments such as coastal areas or industrial zones. Ideal for roofing, framing, and infrastructure, these coils are the backbone of modern construction.

Product Specifications

| Parameter | Details |

|---|---|

| Thickness | 0.13mm – 4.0mm (Customizable) |

| Width | 600mm – 1500mm |

| Zinc Coating | 40–300 g/m² (Adjustable per ASTM A653/EN 10346) |

| Hardness (HRB) | 50–85 (G300, G550 grades available) |

| Surface Finish | Regular/Minimal/Zero Spangle; Chromate Passivation or Oiled |

| Tensile Strength | 350–550 MPa |

| Yield Strength | 250–450 MPa |

| Application | Roofing, Wall Panels, 1 3 4 hot dipped galvanized coil roofing nails, Structural Framing |

| Packaging | Waterproof Wrapping, Steel Pallets (Coil ID: 508mm/610mm) |

Technical Properties & Performance

1. Tensile Strength & Bendability

The galvanized steel coils exhibit a tensile strength range of 350–550 MPa, achieved through precision cold-rolling and annealing processes. This ensures structural integrity under extreme loads, making them suitable for roofing sheets, industrial machinery, and high-stress frameworks. Bendability is optimized with a minimum bend radius of 1.5x thickness, preventing cracks even in complex forming operations.

2. Anti-Rust Mechanism

The hot-dipped galvanized coating provides dual protection:

- Zinc Layer: Acts as a sacrificial barrier, corroding before the steel substrate.

- Anti-Rust Oil: A transparent oil layer further blocks moisture and UV exposure, extending lifespan by 20–30 years.

3. Weight Calculation

Calculate coil weight using:

Example: A 1.5mm-thick, 1200mm-wide coil weighs 14.13 kg/m².

4. Identification & Grading

Coils are labeled per international standards (e.g., ASTM A653 or EN 10346):

- Coating Mass: Z275 (275 g/m² zinc).

- Grade: DX51D (construction), S350GD (structural).

- Surface Code: Oiled (O), Chromated (C).

5. Causes of Stainless Steel Rusting

While stainless steel is corrosion-resistant, rusting may occur due to:

- Chloride Exposure: Coastal or de-icing salt environments degrade passive layers.

- Mechanical Damage: Scratches or abrasions expose underlying steel.

- Chemical Contamination: Contact with acids or iron particles accelerates oxidation.

Why Choose Our Galvanized Steel Coils?

1. Precision Manufacturing

As trusted galvanized steel coil manufacturers, we use laser-guided cold-rolling mills and automated galvanizing lines to ensure:

- Coating Uniformity: ±0.02mm thickness tolerance.

- Surface Perfection: Zero spangle for aesthetic applications.

2. Custom Solutions

- Tailored Dimensions: Non-standard widths (up to 3000mm) or lengths.

- Specialized Coatings: Chromate passivation for enhanced adhesion in painted systems.

- Certifications: CE, ISO 9001, and RoHS compliance.

3. Cost-Effective Durability

- Low Maintenance: Reduced lifecycle costs for infrastructure projects.

- Recyclability: 100% recyclable material, supporting green building initiatives.

4. Global Logistics & Support

- Fast Delivery: Partnered logistics ensure timely shipments to 50+ countries.

- 24/7 Technical Support: Expert guidance on material selection and fabrication.

Applications

- Roofing & Cladding: Compatible with 1 3 4 hot dipped galvanized coil roofing nails for secure installation.

- Structural Framing: High-strength G550 grade for skyscrapers and bridges.

- Industrial Machinery: Corrosion-resistant casings and components.

Why Choose Our Stainless Steel Solutions? (Bottom of Page)

While our galvanized steel coils excel in rust prevention, our stainless steel range is ideal for ultra-demanding environments:

- Premium Alloys: 304/316L grades with 18% chromium and 8–10% nickel.

- Certified Quality: ASTM A240, EN 10088-2 compliant.

- Aesthetic Versatility: Brushed or mirror finishes for architectural projects.