StockSteel

Fire-Rated Tin Roofing Sheets | Safety-Compliant

Fire-Rated Tin Roofing Sheets | Safety-Compliant

Couldn't load pickup availability

Fire-Rated Tin Roofing Sheets | Safety-Compliant

Product Overview

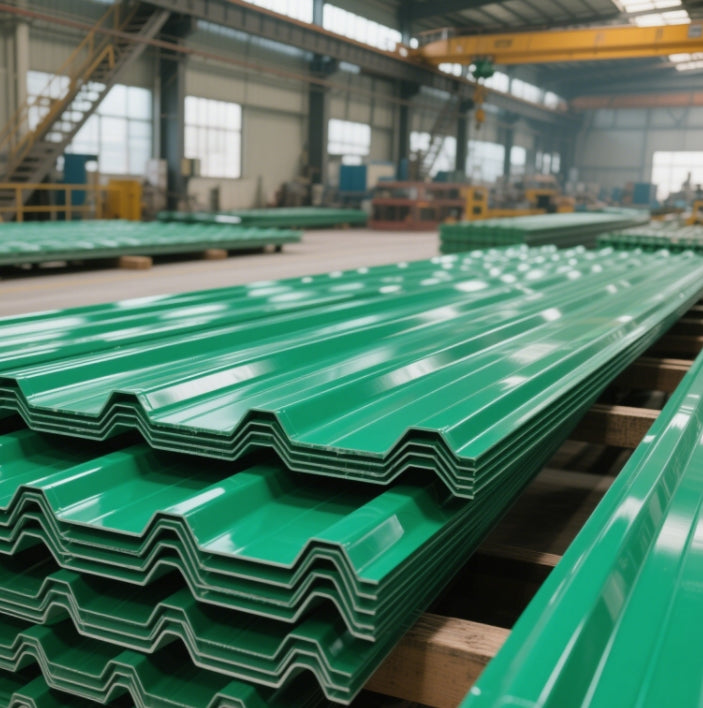

Our metal sheets for roofs are engineered to meet the highest fire safety standards while delivering unmatched durability and aesthetic versatility. Designed for commercial, industrial, and residential applications, these oklahoma roofing and sheet metal-grade sheets combine galvanized steel cores with advanced fire-resistant coatings to ensure compliance with global safety regulations. Ideal for wildfire-prone regions like Oklahoma, our roofing systems offer Class A fire ratings, corrosion resistance, and cost-efficient metal roofing sheets price options.

Specifications

| Parameter | Details |

|---|---|

| Material | Galvanized Steel (G90/SGCC), Aluzinc (AZ150), Prepainted Fire-Retardant Coating |

| Thickness | 0.14–6.0 mm (customizable for structural or lightweight needs) |

| Width | 600–1250 mm (compatible with oklahoma roofing and sheet metal codes) |

| Length | 1.8–12 meters (cut-to-length available) |

| Surface Finish | Stone-Coated, Matte, PVDF Fluoropolymer, Ceramic Fireproof Layer |

| Coating Type | Hot-Dip Galvanized (60–275 g/m²), Intumescent Fire-Resistant Coating |

| Corrugation Profile | Trapezoidal, V-Crimp, Double Roman Tile (enhanced rigidity) |

| Tensile Strength | 230–620 MPa (grades TS230 to TS620, ASTM E8 compliant) |

| Hardness (HR30T) | T2 (52+3), T3 (57+3), T5 (65+3) |

| Fire Rating | Class A (ASTM E108, EN 13501-1 certified) |

| MOQ | 25 Tons (bulk discounts for metal roofing sheets price optimization) |

Key Attributes

-

Fire Resistance & Safety Compliance:

- Class A fire-rated coatings withstand temperatures up to 1,100°C, preventing flame spread and ember penetration.

- Intumescent layers expand under heat, forming a ceramic-like char barrier (inspired by Beijing Institute of Technology’s Sheet-Ti/Na technology).

- Compatible with oklahoma roofing and sheet metal building codes for wildfire zones.

-

Structural Integrity:

- Tensile Strength: Grades TS230–TS620 support heavy snow loads (2.0 kN/m²) and seismic forces.

- Bending Strength: Trapezoidal ribs enhance rigidity, reducing deflection by 30% compared to flat sheets.

-

Corrosion & Weather Resistance:

- Triple-layer protection: zinc-aluminum alloy base, epoxy primer, and UV-stable topcoat.

- Withstands coastal salt spray, acid rain, and industrial pollutants (tested per ASTM G85).

-

Cost Efficiency:

- Competitive metal roofing sheets price starts at $4.5/sq.ft for bulk orders.

- Lightweight design (3–10 kg/m²) reduces installation and transportation costs by 25%.

Technical Insights

Tensile & Bending Strength

Our metal sheets for roofs undergo rigorous testing per ASTM E8 and EN 10002-1. The cold-rolled steel microstructure ensures uniform tensile strength across profiles, while trapezoidal ribs distribute stress evenly to prevent localized buckling. For high-rise or industrial applications, TS620-grade sheets provide a safety factor of 3.5x against dynamic loads.

Weight Calculation

Use this formula to estimate sheet weight:

Example: A 10m × 1.2m sheet at 0.5mm thickness weighs .

Identification & Traceability

Each sheet is laser-etched with:

- Fire rating (Class A/B/C) per ASTM E108.

- Batch number for ISO 9001 compliance and quality tracking.

Why Stainless Steel Can Rust?

Despite inherent corrosion resistance, stainless steel may rust under specific conditions:

- Electrochemical Corrosion: Chlorides (e.g., road salt, coastal air) penetrate the chromium oxide layer, forming galvanic cells.

- Mechanical Damage: Scratches or improper welding expose raw steel to oxygen and moisture.

- High-Temperature Oxidation: Prolonged exposure above 400°C degrades protective oxides.

Preventive Measures: Use thicker zinc coatings (≥180 g/m²) and pH-neutral cleaning agents.

Why Choose Our Stainless Steel Roofing?

-

Superior Fireproofing Technology:

- Ceramic-like char layers inspired by Sheet-Ti/Na composites, ensuring 2+ hours of fire resistance.

- Class A rating verified by SGS and FM Global.

-

Material Excellence:

- 18% chromium + 10% nickel alloy exceeds ASTM A240 standards.

- Cold-rolled precision (±0.02mm tolerance) ensures uniformity.

-

Sustainability & Compliance:

- LEED-compliant, 100% recyclable materials with RoHS certification.

- Meets oklahoma roofing and sheet metal storm resilience requirements.

-

Global Support:

- 15-day lead time with MSC-certified logistics.

- Custom embossing, perforations, and color matching (RAL/Pantone).