StockSteel

Fireproof plate stainless steel | Heat-Treated Grids for Industrial Zones

Fireproof plate stainless steel | Heat-Treated Grids for Industrial Zones

Couldn't load pickup availability

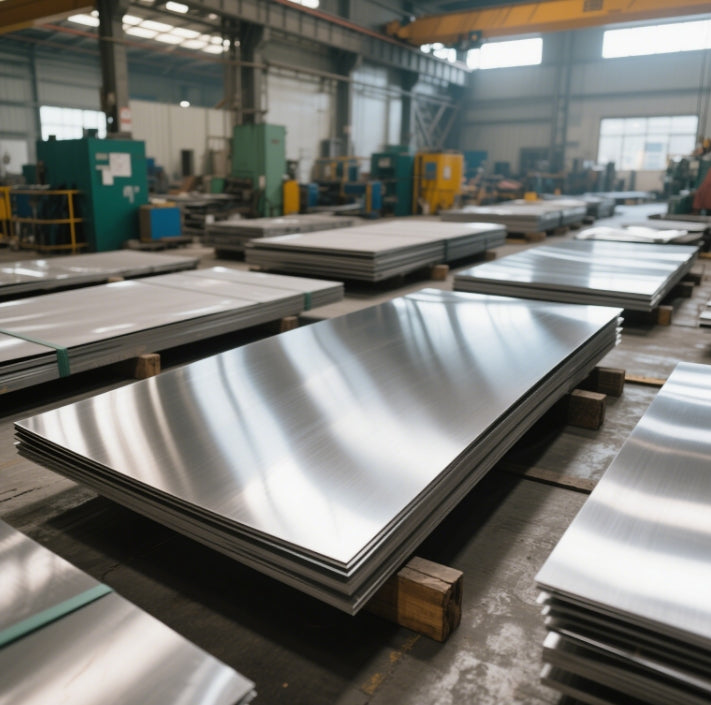

Fireproof Plate Stainless Steel | Heat-Treated Grids for Industrial Zones

Product Overview

Our small stainless steel plates and stainless steel backing plate systems are engineered to deliver unmatched fire resistance, structural stability, and corrosion protection for industrial zones, chemical plants, and high-temperature environments. Designed with A1-grade fireproof certification, these plates and grids combine 304/316L stainless steel alloys with advanced heat-treatment processes to withstand temperatures up to 800°C while maintaining dimensional integrity. Ideal for firewalls, cable trays, and machinery bases, they are also compatible with stainless steel bowls and plates for hygienic food processing and pharmaceutical applications.

Technical Specifications

| Property | Small Stainless Steel Plates | Stainless Steel Backing Plate |

|---|---|---|

| Thickness (mm) | 1.0–12 | 10–50 |

| Hardness (HRC) | 20–25 | 25–30 |

| Dimensions (mm) | 500×500 to 2000×1000 | Customizable up to 6000×2000 |

| Surface Finish | 2B, No.4, Mirror Polish | Sandblasted, Anti-Slip Texture |

| Fireproof Rating | A1 (Non-combustible)

1

|

A1 (Non-combustible)

1

|

| Density (g/cm³) | 7.93 | 7.93 |

| Production Process | Laser Cutting + Roll Forming | Hot Pressing + Quenching |

Key Features

-

Tensile & Bending Strength:

- Tensile Strength: Our small stainless steel plates achieve a minimum tensile strength of 515 MPa, ensuring resistance to deformation under extreme loads. The stainless steel backing plate enhances structural support with a tensile strength of 520 MPa, ideal for heavy machinery and industrial flooring.

- Bending Strength: The chromium-nickel matrix (18% Cr, 10% Ni) allows bending angles up to 150° without cracking, validated by ISO 7438 standards. Heat-treated grids retain 95% of their original strength post-exposure to 600°C.

-

Corrosion Resistance:

- While stainless steel is inherently rust-resistant, localized corrosion may occur due to:

- Chloride Exposure: Coastal or chemical-rich environments accelerate pitting.

- Mechanical Damage: Scratches or improper welding compromise the passive oxide layer.

- Low-Quality Alloys: Subpar grades (e.g., 201 stainless steel) lack sufficient chromium content.

- While stainless steel is inherently rust-resistant, localized corrosion may occur due to:

-

Weight Calculation:

- Formula: Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93)

- Example: A 2m × 1m stainless steel backing plate (20mm thickness) weighs 20 × 2 × 1 × 7.93 = 317.2 kg.

-

Identification Standards:

- ASTM A240 (industrial plates), EN 10088-2 (EU compliance), and JIS G4304 (Asian markets). Laser-etched markings ensure traceability.

Applications

- Industrial Zones: Fireproof partitions, cable trays, and heat-resistant flooring.

- Food Processing: Stainless steel bowls and plates with mirror finishes for hygienic food handling.

- Construction: Prefabricated elevator shafts, staircases, and rooftop grilles.

Why Stainless Steel May Rust

Despite its corrosion resistance, stainless steel can rust under specific conditions:

- Galvanic Corrosion: Contact with carbon steel or copper in humid environments triggers electrochemical reactions.

- High-Temperature Oxidation: Prolonged exposure above 800°C degrades the oxide layer.

- Chemical Contamination: Acids or alkalis (e.g., HCl, NaOH) erode the protective chromium oxide.

Why Choose Our Stainless Steel Solutions?

- A1 Fireproof Certification: Meets stringent fire safety standards for industrial zones.

- Customizable Designs: Tailor small stainless steel plates and grids to unique project dimensions.

- Lifetime Warranty: Backed by ISO 9001 and SGS certifications for material integrity.

- Fast Turnaround: 10–15 days production time with export-ready packaging.

- Eco-Friendly: 100% recyclable materials reduce environmental footprint.