StockSteel

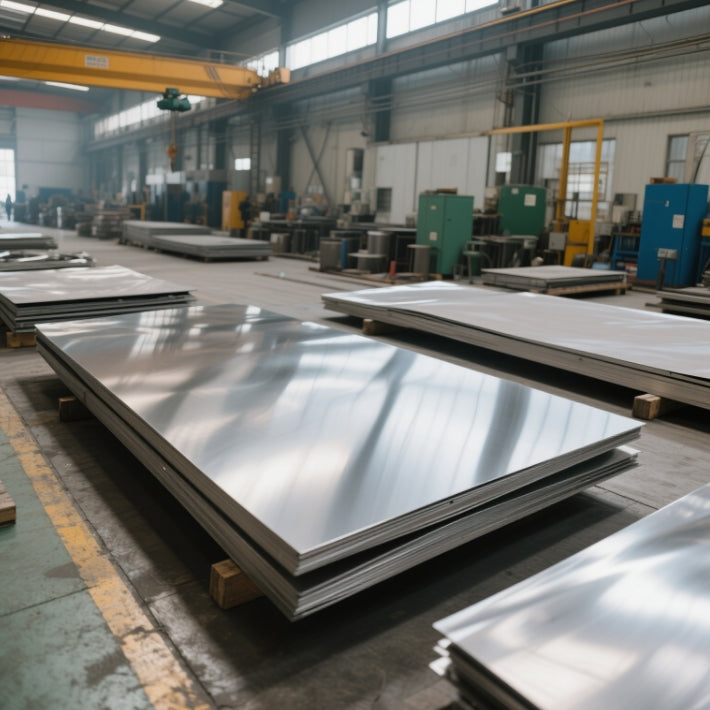

Heat-Treated stainless steel plate | Enhanced Strength for Machinery & Tools

Heat-Treated stainless steel plate | Enhanced Strength for Machinery & Tools

Couldn't load pickup availability

Heat-Treated Stainless Steel Plate | Enhanced Strength for Machinery & Tools

Product Specifications

| Attribute | Details |

|---|---|

| Material Grade | 304 stainless steel plate (ASTM A240/A480, EN 1.4301, JIS SUS304) |

| Thickness | 0.5mm – 50mm (Customizable) |

| Width | 1000mm – 2500mm |

| Length | 2000mm – 6000mm |

| Surface Finish | Mirror Polish, Brushed (No.4), Satin, Anti-Slip Diamond Checkered |

| Hardness | HRB 80-95 (Annealed), HRC 25-40 (Heat-Treated) |

| Density | 7.93 g/cm³ |

| Heat Treatment | Solution Annealing, Quenching, Stress Relieving |

Key Features & Benefits

-

Superior Mechanical Strength

Heat-treated 304 stainless steel plate achieves enhanced tensile and bend strength, making it ideal for machinery, tools, and structural components. -

Corrosion Resistance

Chromium-nickel alloy (18% Cr, 8% Ni) forms a self-healing oxide layer, resisting rust in harsh environments like marine or chemical industries. -

Versatile Applications

Suitable for dinner plates stainless steel production (food-grade safety) and gold plated stainless steel jewelry due to its hypoallergenic properties. -

Custom Fabrication

Compatible with laser cutting, CNC machining, and stamping for precision parts.

Technical Details

1. Tensile Strength

Tensile strength measures the maximum stress a material withstands before breaking. Heat-treated 304 stainless steel plate shows exceptional performance:

- Annealed State: 515–1035 MPa (varies with thickness and processing).

- Cold-Worked State: Up to 1320 MPa due to strain hardening.

Testing follows ASTM E8 standards, ensuring consistency across batches.

2. Bend Strength

Bend strength determines flexibility under deformation. Our plates excel in three-point bending tests (ASTM E290):

- Cold-Rolled Plates: Achieve 180° bends without cracking, ideal for forming gold plated stainless steel jewelry molds.

- Heat-Treated Plates: Retain ductility even after hardening, suitable for machinery parts requiring both strength and formability.

3. Identification & Marking

- Laser Etching: Permanent grade markings (e.g., "304," "1.4301") for traceability.

- Heat Numbers: Unique batch codes linked to mill test certificates (MTCs).

- Surface Codes: "2B" for cold-rolled, "BA" for bright annealed finishes.

4. Weight Calculation

Formula:

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93)

Example: A 10mm × 1.5m × 3m plate weighs 357.3 kg.

5. Why Does Stainless Steel Rust?

Despite its corrosion resistance, rust can occur due to:

- Chloride Exposure: Saltwater or de-icing agents degrade the chromium oxide layer.

- Mechanical Damage: Scratches or welding defects expose the base metal to oxidation.

- Improper Maintenance: Accumulation of iron particles or acidic residues accelerates corrosion.

Applications

| Industry | Use Cases |

|---|---|

| Machinery & Tools | Gears, valves, hydraulic components |

| Food Processing | Dinner plates stainless steel, cookware, fermentation tanks |

| Jewelry & Decor | Gold plated stainless steel jewelry, architectural panels |

| Automotive | Exhaust systems, fasteners, structural frames |

Why Choose Our Stainless Steel Plates?

- Certified Quality: Compliant with ASTM, EN, ISO, and JIS standards.

- Enhanced Durability: Heat treatment optimizes strength-to-weight ratios for demanding applications.

- Sustainable Manufacturing: 70% recycled content, zero VOC emissions.

- Global Logistics: 15-day lead time, door-to-door shipping with customs support.

- Technical Expertise: Free CAD design services and material selection guidance.