StockSteel

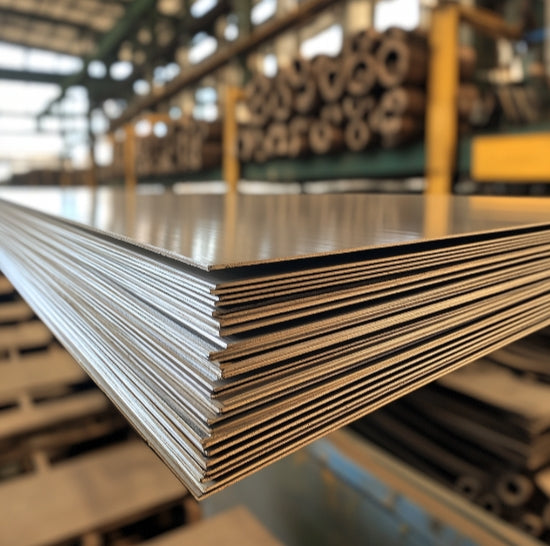

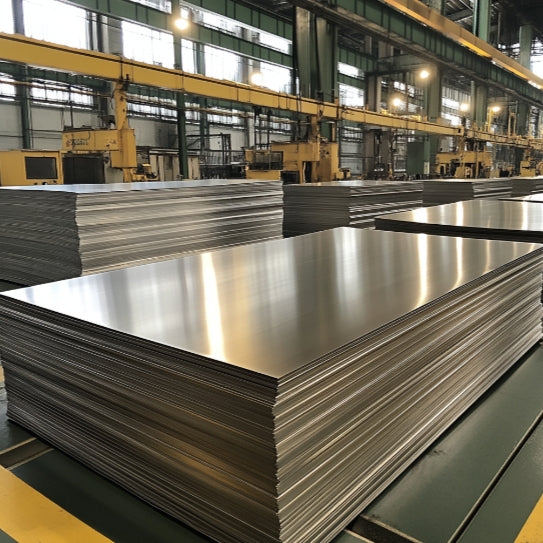

Heavy-Duty Stainless Steel 409 Sheet Plate – Industrial Use

Heavy-Duty Stainless Steel 409 Sheet Plate – Industrial Use

Couldn't load pickup availability

Stainless Steel Plate/Sheet Product Details

Product Specifications

Material Grades & Standards

| Grade Series | Common Grades | Standards (ASTM/AISI/DIN/EN/JIS) | Surface Finish |

|---|---|---|---|

| 200 Series | 201, 202 | ASTM A240, JIS SUS201 | No.4, HL, 8K Mirror |

| 300 Series | 304 grinding stainless steel sheet plate, 304L, 316, 316L | ASTM A480, EN 1.4301/1.4404 | 2B, BA, Polished, Embossed |

| 400 Series | 430, 436, 410 | ASTM A167, JIS SUS430 | 2D, Bead Blasted, Titanium Coated |

| Duplex | 2205, 2507 | ASTM A240, UNS S32205 | Cold Rolled, Hot Rolled |

Mechanical Properties

| Property | 304/304L | 316/316L | 430 | Duplex 2205 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 515–1035 | 515–690 | 450–600 | 620–895 |

| Yield Strength (MPa) | ≥205 | ≥170 | ≥206 | ≥450 |

| Hardness (HBW) | ≤201 | ≤217 | ≤183 | ≤290 |

| Elongation (%) | ≥40 | ≥40 | ≥22 | ≥25 |

Dimensions & Tolerances

| Thickness (mm) | Width (mm) | Length (mm) | Edge Type | Tolerance |

|---|---|---|---|---|

| 0.1–3 (Cold) | 100–2000 | 100–12000 | Mill, Slit | ±0.02–0.1mm |

| 3–100 (Hot) | 1000–2000 | 2000–6000 | Sheared | ±1%–3% |

Key Features & Technical Insights

Tensile Strength

Tensile strength measures a material’s resistance to breaking under tension. For 304 grinding stainless steel sheet plate, the range of 515–1035 MPa ensures durability in high-stress applications like construction beams, chemical tanks, and automotive components. Cold-rolled variants exhibit higher strength due to work hardening, while hot-rolled plates prioritize formability.

Bending Strength

Bending strength correlates with tensile properties but focuses on deformation under load. Austenitic grades (e.g., 304) offer superior ductility, allowing bends up to 180° without cracking. Ferritic grades (e.g., 430) require careful handling to avoid brittleness. For gold plated stainless steel sheet, post-plating annealing ensures flexibility while maintaining surface integrity.

Identification Methods

Stainless steel grades are identified via:

- Chemical Analysis: Using XRF or spark testing to verify Cr (≥10.5%), Ni (8–10% for 304), and Mo (2–3% for 316).

- Magnetism: Austenitic grades (304/316) are generally non-magnetic; slight magnetism may occur after cold working.

- Surface Marking: Laser-etched labels (e.g., “ASTM A240”) or color-coded edges for quick recognition.

Weight Calculation Formula

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93 g/cm³)

Example: A 2mm × 1m × 2m china stainless steel plate sheet weighs:

2 × 1 × 2 × 7.93 = 31.72 kg.

Why Does Stainless Steel Rust?

Despite its corrosion resistance, stainless steel can rust under specific conditions:

- Chloride Exposure: Coastal environments or de-icing salts accelerate pitting corrosion, especially in 304 (vs. 316’s superior chloride resistance).

- Surface Contamination: Organic residues (food, grease) or iron particles from tools create localized galvanic cells, breaking the passive oxide layer.

- Mechanical Damage: Scratches or weld zones reduce chromium concentration, weakening corrosion protection.

- Improper Cleaning: Harsh abrasives or chlorine-based cleaners degrade surface finishes like mirror or gold plated stainless steel sheet.

Why Choose Our Stainless Steel Plates/Sheets?

- Unmatched Quality Control: All products comply with ISO 9001, SGS, and ASTM standards, with third-party inspections for chemical composition and mechanical properties.

- Customization Capabilities: Tailor thickness (0.01mm–100mm), width (up to 6000mm), and surface finishes (mirror, embossed, 304 grinding stainless steel sheet plate) to your project needs.

- Competitive Pricing: Direct factory pricing for china stainless steel plate sheet, with volume discounts and FOB/CIF logistics flexibility.

- Fast Delivery: 15,000+ tons of ready stock and partnerships with global freight forwarders ensure 7–15 day lead times.

- Eco-Friendly: 100% recyclable materials align with sustainable manufacturing practices.