StockSteel

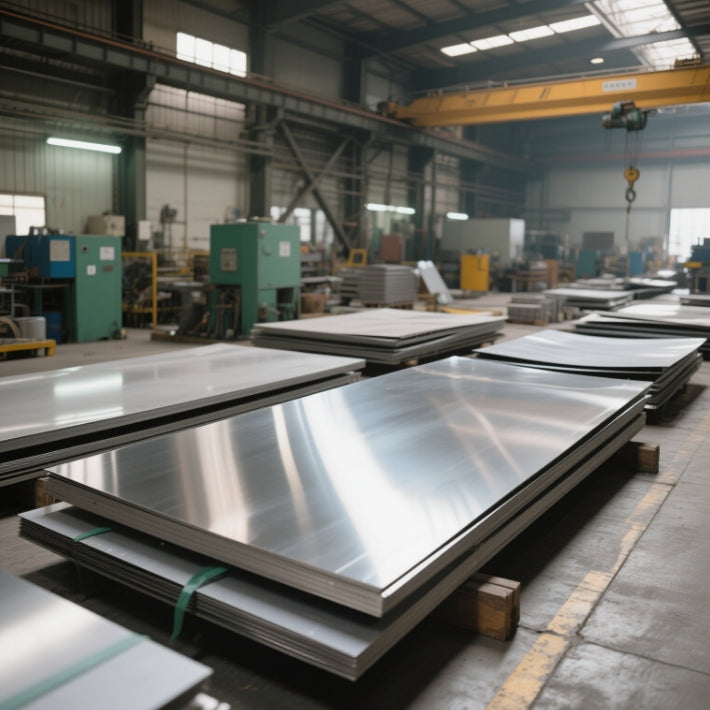

Heavy-Duty Stainless Steel Metal Plate | S31600 & HL Surface

Heavy-Duty Stainless Steel Metal Plate | S31600 & HL Surface

Couldn't load pickup availability

Heavy-Duty Stainless Steel Metal Plate | S31600 & HL Surface

Technical Specifications

| Parameter | Details |

|---|---|

| Material Grade | S31600 (Equivalent to ASTM 316 / EN 1.4401) |

| Thickness Range | 0.4 mm – 25 mm (Customizable for stainless steel griddle plate designs) |

| Hardness (Surface) | HRB 70–90 (Annealed); HRC ≤20 (Cold-Worked) |

| Dimensions | Width: 1000–4500 mm; Length: Custom-cut up to 12,000 mm |

| Tensile Strength | 520–720 MPa |

| Yield Strength | ≥205 MPa |

| Elongation | ≥40% |

| Surface Finish | 2B (Matte), HL (High-Gloss Polished), stainless steel gold plate |

| Weight Formula | Weight (kg) = Thickness (mm) × Area (m²) × 7.93 (Density in g/cm³) |

| Thermal Conductivity | 16.3 W/m·K (100°C) |

| Melting Point | 1375–1390°C |

Performance Attributes

1. Tensile & Bend Strength

The S31600 grade combines high tensile strength (520–720 MPa) with exceptional bend resistance (1.5× tensile strength) due to its austenitic microstructure stabilized by 16–18% chromium, 10–14% nickel, and 2–3% molybdenum. This makes it ideal for heavy-duty applications like structural beams, stainless steel griddle plates, or marine hardware. The material retains its integrity under dynamic loads up to 500°C, preventing deformation or cracking.

2. Identification & Certification

- ASTM Standards: Laser-etched UNS S31600 identifiers ensure traceability.

- EN 1.4401 Compliance: Meets EU standards for chemical composition and mechanical properties.

- Surface Marking: Includes mill codes, heat numbers, and stainless steel gold plated chain compatibility notes for industrial tracking.

3. Weight Calculation

Use the formula:

For example, a stainless steel gold plate with a 3 mm thickness and 2 m² area weighs 47.58 kg.

4. Causes of Stainless Steel Rust

Despite its corrosion resistance, localized rust may occur due to:

- Chloride Exposure: Coastal salt or industrial chemicals degrade the passive chromium oxide layer.

- Mechanical Damage: Scratches or improper welding expose the base metal to oxidation.

- Thermal Stress: Rapid temperature changes (e.g., in stainless steel griddle plates) can induce micro-cracks, accelerating corrosion.

Material Advantages

Enhanced Durability

- Molybdenum Boost: 2–3% molybdenum enhances resistance to pitting and crevice corrosion, making it suitable for marine or chemical environments.

- High-Temperature Stability: Retains 85% of its strength at 500°C, ideal for industrial ovens or exhaust systems.

Precision Manufacturing

- HL Polishing: Achieves ≤Ra 0.1 μm surface roughness for stainless steel gold plate aesthetics or hygienic food-grade surfaces.

- Laser Cutting: Tolerance ±0.1 mm ensures seamless integration into architectural grids or machinery.

Sustainability

- 100% Recyclable: Reduces environmental impact and lifecycle costs.

Why Choose Our S31600 Stainless Steel?

-

Certified Material Integrity

- Dual-certified (ASTM 316 & EN 1.4401) with mill test reports for traceability.

- Optional nitrogen-enriched variants (S31600N) for enhanced strength in stainless steel gold plated chain applications.

-

Customization Flexibility

- Tailored dimensions for curved architectural elements or stainless steel griddle plates.

- Available in matte, HL-polished, or stainless steel gold plate finishes.

-

Technical Expertise

- Free consultation on welding protocols, corrosion prevention, and load calculations.

-

Industry-Leading Warranty

- 10-year warranty against material defects and premature corrosion.