StockSteel

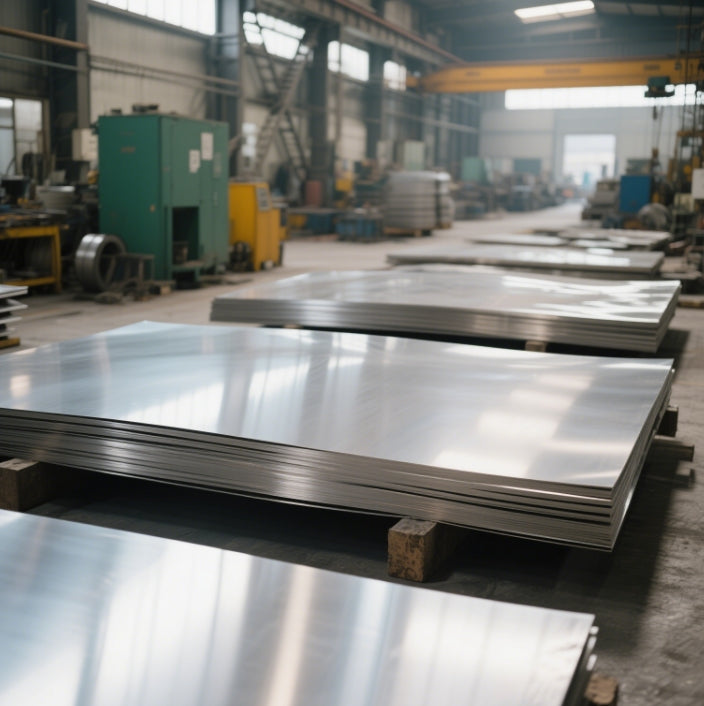

High-Performance plate stainless steel | Export-Optimized 304/316 Workshop Plates

High-Performance plate stainless steel | Export-Optimized 304/316 Workshop Plates

Couldn't load pickup availability

High-Performance Stainless Steel Plates | Export-Optimized 304/316 Workshop Plates

Product Specifications

| Parameter | Details |

|---|---|

| Material Grade | 304 / 304L / 316 / 316L (ASTM A240, AISI, EN 1.4301/1.4401) |

| Thickness | 3mm–120mm (Hot Rolled), 0.5mm–6.0mm (Cold Rolled) |

| Width | 1000mm, 1219mm, 1250mm, 1500mm (Customizable) |

| Length | 2000mm, 2438mm, 3000mm, 6000mm (Tailored Cutting Available) |

| Surface Finish | No.1 (Hot Rolled), 2B (Cold Rolled), Ion Plated Stainless Steel Durability Options |

| Hardness (HRB/HRC) | 304: ≤ 187HB / ≤ 90HRB; 316: ≤ 200HV |

| Processing | Cold/Hot Rolling, Grinding, Polishing, Lutron Stainless Steel Wall Plate Fabrication |

| Certifications | ISO 9001, SGS, BV, TUV |

Mechanical & Physical Properties

Tensile Strength

Our 304/316 stainless steel plates exhibit exceptional tensile strength, ensuring structural integrity under heavy loads.

- 304: Minimum 520 MPa (75,000 psi)

- 316: Minimum 620 MPa (90,000 psi)

This resistance to deformation makes them ideal for pressure vessels, marine components, and chemical processing equipment.

Bending Strength

The high ductility of austenitic stainless steel allows for precise bending without cracking. Cold-rolled plates (e.g., 0.5–3mm thickness) achieve a bending radius of 1–2 times the material thickness, while hot-rolled plates (≥4mm) require 3–4 times.

Identification & Marking

Stainless steel grades are laser-etched or stamped with standardized codes:

- 304: UNS S30400 / AISI 304

- 316: UNS S31600 / AISI 316

Certificates include mill test reports (MTRs) detailing chemical composition, heat treatment, and compliance with ASTM/EN standards.

Weight Calculation Formula

Calculate plate weight using:

Example: A 3mm × 1.5m × 6m 304 plate weighs .

Why Does Stainless Steel Rust?

While stainless steel resists corrosion, improper use or environmental factors may cause rust:

- Low Chromium Content: Grades with <10.5% Cr lose passivation layer integrity.

- Chloride Exposure: Coastal or chemical environments accelerate pitting in 304; 316’s molybdenum enhances chloride resistance.

- Poor Manufacturing: Substandard smelting leaves impurities, reducing corrosion resistance.

- Mechanical Damage: Scratches or welding without post-treatment expose raw metal to oxidation.

Applications & Customization

- Industrial: Chemical tanks, heat exchangers, ion plated stainless steel durability components for aerospace.

- Architectural: Decorative façades, Lutron stainless steel wall plate systems, handrails.

- Consumer Goods: Kitchenware, medical tools, is gold plated stainless steel good for jewelry (corrosion-resistant base).

Why Choose Our Stainless Steel Plates?

- Global Compliance: Meet ASTM, EN, JIS, and GB standards for seamless export.

- Precision Engineering: Custom thickness (±0.05mm), width/length (±1mm), and surface finishes (brushed, mirrored, etched).

- Certified Durability: Third-party validated mechanical properties and corrosion resistance.

- Sustainable Solutions: Recyclable material with 10+ years of service life in harsh conditions.

- One-Stop Service: From raw material sourcing to logistics—optimized for global workshops.