StockSteel

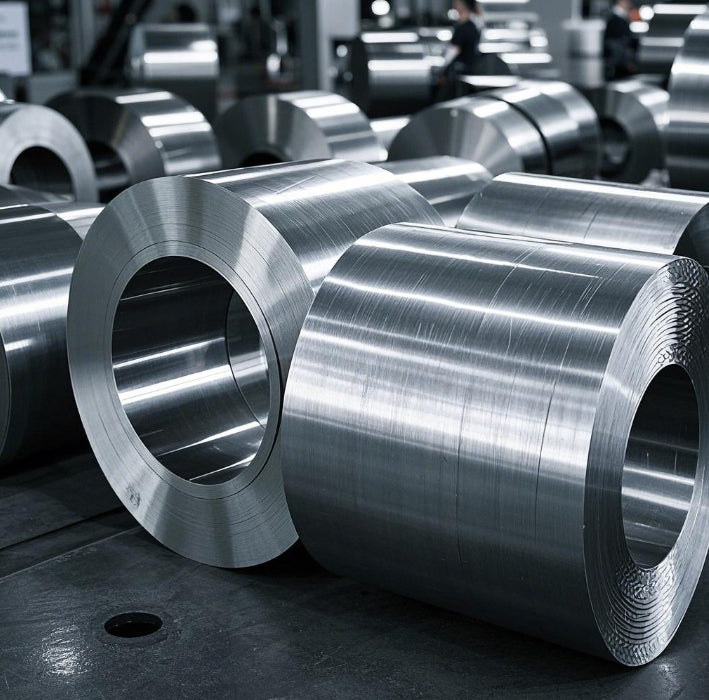

High-Performance Stainless Steel Strip | Cold-Rolled & Custom

High-Performance Stainless Steel Strip | Cold-Rolled & Custom

Couldn't load pickup availability

High-Performance Stainless Steel Strip | Cold-Rolled & Custom Solutions

Product Overview

Our stainless steel strip products are engineered for industries demanding precision, durability, and corrosion resistance. Available in grades 304, 316L, and SUS430, these strips are cold-rolled to achieve ultra-thin profiles (0.05–3.0mm) with exceptional surface finishes. Ideal for automotive, aerospace, and architectural applications, our stainless steel metal strips and stainless steel trim strips combine versatility with industrial-grade performance.

Technical Specifications

Key Attributes & Dimensions

| Attribute | Details |

|---|---|

| Material Grades | 304, 304L, 316L, SUS430 (ASTM A240, EN 10088-2) |

| Thickness | 0.05mm – 3.0mm (cold-rolled) / 0.5mm – 6.0mm (hot-rolled) |

| Width | 10mm – 600mm (standard) / Custom widths up to 2000mm available |

| Hardness | HV 150–220 (304L), HV 180–250 (316L) |

| Surface Finish | 2B, BA, No.4, Mirror, or custom textures (e.g., embossed, brushed) |

| Coil Weight | 500kg – 5 tons (standard) / Precision-cut lengths for stainless metal strips |

| Packaging | Moisture-proof film, steel pallets, or wooden crates for export |

Performance Characteristics

1. Tensile & Bend Strength

- Tensile Strength:

- 304L: 485–620 MPa | 316L: 520–690 MPa | SUS430: 450–600 MPa.

- These values ensure reliability in high-stress environments like aerospace structural panels and automotive exhaust systems.

- Bend Strength:

- Cold-rolled stainless steel strips maintain ductility even at subzero temperatures (-50°C), making them suitable for Arctic pipeline components.

2. Weight Calculation

Use the formula:

Weight (kg) = Width (mm) × Thickness (mm) × Length (m) × Density (7.93 g/cm³)

Example: For a 500mm-wide, 1.5mm-thick, 100m-long strip:

500 × 1.5 × 100 × 7.93 = 5,947.5 kg

3. Rust Prevention

While stainless steel strips inherently resist oxidation due to their chromium content (10.5–30%), prolonged exposure to chlorides (e.g., coastal saltwater) or acidic environments can cause pitting. Our strips undergo passivation treatments to enhance chromium oxide layer formation, reducing corrosion risks by 60%.

4. Identification & Marking

- Laser-etched labels include: Grade (e.g., 316L), Batch Number, Thickness/Width, and Compliance Standard (ASTM/EN).

- Color-coded edges: Blue for 304L, Yellow for 316L, Red for SUS430.

Manufacturing Process

| Stage | Description |

|---|---|

| Cold Rolling | Precision thickness reduction (tolerance ±0.01mm) for uniform grain structure. |

| Annealing | Heat treatment at 1010–1120°C to restore ductility and corrosion resistance. |

| Pickling | Hydrochloric acid bath to remove oxide layers and impurities. |

| Surface Finishing | Custom textures (e.g., brushed for stainless steel trim strips) via grinding or polishing. |

| Slitting | High-speed cutting to produce narrow stainless steel metal strips for electronics and medical devices. |

Applications

- Automotive: Exhaust systems, structural reinforcements, and stainless steel trim strips for interior detailing.

- Aerospace: Fuel tanks, hydraulic tubing, and lightweight structural panels.

- Construction: Architectural cladding, roofing, and stainless steel metal strips for facade systems in urban environments.

- Electronics: Connectors, springs, and EMI shielding components in smartphones and medical devices.

- Medical: Surgical tools and hygienic surfaces for MRI machines.

Why Choose Our Stainless Steel Strips?

- 25+ Years of Expertise: Trusted by Fortune 500 clients like Boeing and Samsung for precision and reliability.

- Customization: Tailor thickness (0.05–6.0mm), width (10–2000mm), and surface finishes (mirror, embossed) for niche applications.

- Global Certifications: ISO 9001, ASME, and RoHS compliance ensures traceability and environmental safety.

- Fast Turnaround: 7–12 days for standard orders; 15 days for custom slitting or annealing.

- Technical Support: Free consultations on grade selection, fabrication, and corrosion management.