StockSteel

High-Pressure galvanized pipe | Industrial-Grade Fluid Transport

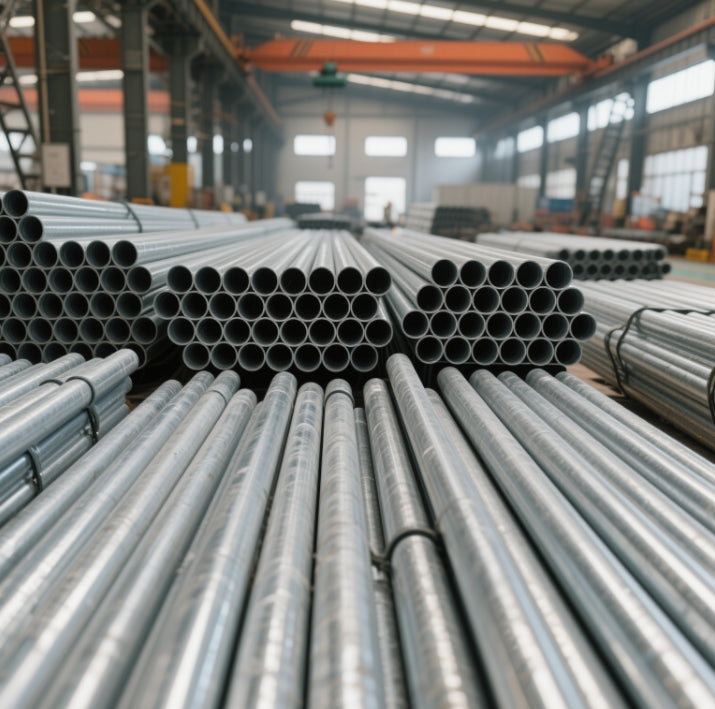

High-Pressure galvanized pipe | Industrial-Grade Fluid Transport

Regular price

$560.00 SGD

Regular price

Sale price

$560.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

High-Pressure Galvanized Pipe | Industrial-Grade Fluid Transport

Product Specifications

| Parameter | Details |

|---|---|

| Material | Low-carbon steel (Q235, Q345) with hot-dip galvanized coating (70–300 g/m² zinc) |

| Standards | ASTM A53, EN10219, ISO 9001, BS1387 |

| Diameter Range | 1/2" (21.3 mm) to 12" (323.9 mm) for galvanized drain pipe systems |

| Wall Thickness | 1.0–6.0 mm (customizable for high-pressure applications up to 450 psi) |

| Length | Standard: 6 m, 12 m; Custom: 1–12 m (precision cutting galvanized pipe services available) |

| Surface Finish | Smooth spangled finish (hot-dip galvanized) or matte for industrial use |

| Hardness | Rockwell B scale: G350–G550 (ideal for structural and heavy-load uses) |

| Max. Working Pressure | 450 psi (3.1 MPa) |

Key Attributes

-

Corrosion Resistance:

- The hot-dip galvanizing process forms a zinc-iron alloy layer, offering 4–6× longer lifespan than standard black steel pipes. Ideal for coastal, chemical, and high-humidity environments.

- Zinc coating acts as a "sacrificial layer," protecting the base steel even if scratched.

-

Impact Resistance:

- Tensile Strength: 330–550 MPa (Grade Q345 recommended for heavy-duty frameworks).

- Bend Strength: Withstands 180° bending without cracking (tested per ASTM A370).

-

Versatility:

- Suitable for galvanized drain pipe systems, HVAC, and high-pressure fluid transport.

- Compatible with cutting galvanized pipe services for tailored installations.

Manufacturing Process

| Stage | Description |

|---|---|

| Material Prep | Steel coils pickled to remove oxides and fluxed for optimal zinc adhesion. |

| Pipe Formation | High-frequency induction welding (HFIW) ensures seamless joints for high-pressure use. |

| Galvanizing | Immersion in molten zinc (450–465°C) to create a uniform, corrosion-resistant layer. |

| Quality Control | Hydrostatic testing (1.5× working pressure) and salt spray compliance (5,000+ hours). |

Technical Specifications

1. Tensile & Bend Strength

- Tensile Strength: Ranges from 330 MPa (Grade Q195) to 550 MPa (Grade Q345). Higher grades are ideal for load-bearing structures like bridges and industrial frameworks.

- Bend Strength: Achieves a minimum bend radius of 2.5× pipe diameter without fracture (ISO 8491 compliance).

2. Weight Calculation

Formula for galvanized pipe weight:

- Example: A galvanized drain pipe with 88.9 mm OD and 4.0 mm WT weighs ~8.3 kg/m.

3. Identification Marking

- Pipes are stamped with:

- Manufacturer’s logo and ASTM standard (e.g., ASTM A53).

- Size and coating type (HDG for hot-dip).

4. Stainless Steel Rust Causes

While stainless steel resists rust due to a chromium oxide layer, corrosion can occur due to:

- Chloride Exposure: Coastal environments or de-icing salts accelerate pitting.

- Mechanical Damage: Scratches or welding disrupt the oxide layer, exposing the substrate.

- Chemical Contamination: Acids or alkalis degrade protective layers.

5. Lead Content in Galvanized Pipes

A common concern is does galvanized pipe have lead in it. Modern galvanizing processes use pure zinc coatings (99.995% zinc) without lead additives, complying with NSF/ANSI 61 for safe drinking water applications.

Why Choose Our Galvanized Pipes?

- Bulk Pricing Advantage: Competitive rates for industrial projects (FOB: $700–900/ton).

- Custom Solutions: Precision cutting galvanized pipe services and threaded ends for fittings.

- Certified Quality: ISO 9001, RoHS, and ASTM compliance with 5,000+ hours of salt spray testing.

- Global Logistics: Sea-worthy packaging and 15–30 day delivery worldwide.

Why Stainless Steel Stands Out

While galvanized pipes excel in cost-effectiveness, our stainless steel products offer unmatched longevity for specialized applications:

- Superior Corrosion Resistance: Chromium-nickel alloys (e.g., SUS 304/316) resist rust even in acidic or marine environments.

- Hygienic & Low Maintenance: Non-porous surface prevents bacterial growth, ideal for food processing and pharmaceuticals.

- High-Temperature Tolerance: Withstands extreme heat up to 870°C, perfect for boilers and exhaust systems.