StockSteel

High-Quality galvanized pipe | Precision-Cut Steel for Contractors

High-Quality galvanized pipe | Precision-Cut Steel for Contractors

Couldn't load pickup availability

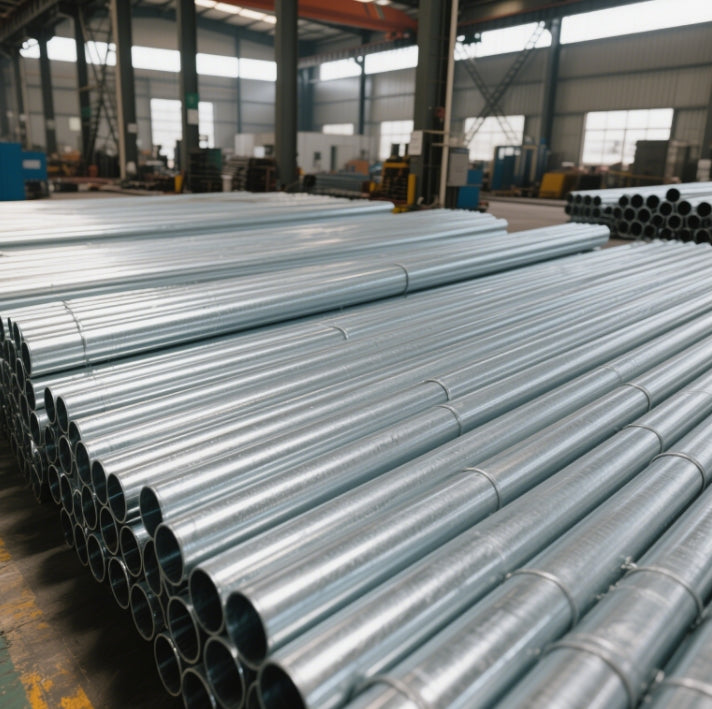

High-Quality Galvanized Pipe | Precision-Cut Steel for Contractors

Product Overview

Our high-quality galvanized pipe combines durability, corrosion resistance, and precision engineering, making it the ideal choice for contractors in construction, plumbing, and industrial applications. Manufactured using advanced hot-dip galvanizing technology, our pipes ensure long-term performance even in harsh environments.

Specifications & Technical Data

| Property | Details |

|---|---|

| Material | Carbon steel with zinc coating (ASTM A53/A123 standards) |

| Standards | ASTM, DIN, EN, JIS |

| Available Sizes | 1 inch galvanized steel pipe (DN25), 3 inch galvanized steel pipe (DN80), 1/2" to 48" |

| Wall Thickness | Sch 10, Sch 40 galvanized pipe, Sch 80, and custom thicknesses |

| Zinc Coating | 40–275 g/m² (hot-dip galvanized) |

| Tensile Strength | 370–550 MPa |

| Yield Strength | 230–450 MPa |

| Hardness | 70–90 HRB (Rockwell B) |

| Surface Finish | Smooth, spangle-free coating for enhanced adhesion |

| Temperature Resistance | -40°C to 200°C |

Key Features

- Superior Corrosion Resistance: The hot-dip galvanized layer forms a protective zinc-iron alloy, preventing rust even in humid or saline environments.

- High Strength-to-Weight Ratio: Ideal for structural applications requiring durability without excessive weight.

- Precision Manufacturing: Tolerances within ±1% ensure seamless integration into complex projects.

- Versatility: Suitable for water supply, gas pipelines, scaffolding, and HVAC systems.

Technical Explanations

Tensile & Bend Strength

Our pipes achieve tensile strength of 370–550 MPa, ensuring resistance to cracking under heavy loads. The bend strength is optimized through cold-forming processes, allowing the pipe to withstand deformation without structural failure. For Sch 40 galvanized pipe, wall thickness ensures exceptional pressure resistance (up to 300 PSI).

Weight Calculation

Use the formula:

Example: A 3 inch galvanized steel pipe (OD: 88.9 mm, WT: 5.49 mm) weighs approximately 11.29 kg/m.

Identification Marking

Pipes are stamped with:

- ASTM standard (e.g., ASTM A53)

- Size (e.g., 1 inch galvanized steel pipe)

- Manufacturer’s logo

- Coating type (hot-dip or electro-galvanized).

Why Stainless Steel Can Rust

While stainless steel resists corrosion, improper handling or environmental factors may cause rust:

- Electrochemical Corrosion: Contact with dissimilar metals in humid conditions creates galvanic cells.

- Chemical Exposure: Acids, chlorides, or industrial pollutants degrade the passive oxide layer.

- Mechanical Damage: Scratches or abrasions expose the underlying steel to oxidation.

- Low-Quality Alloys: Substandard chromium/nickel content reduces corrosion resistance.

Galvanizing Process

- Surface Preparation: Acid pickling removes impurities and oxides.

- Fluxing: Immersion in zinc ammonium chloride to enhance coating adhesion.

- Hot-Dip Galvanizing: Dipping in molten zinc (450°C) to form a metallurgical bond.

- Cooling & Inspection: Air-cooling followed by quality checks for coating uniformity.

Applications

- Construction: Structural frameworks, handrails, and roofing.

- Plumbing: Water distribution systems and sewage lines.

- Agriculture: Irrigation systems and greenhouse structures.

- Mining: Ventilation and slurry transport pipelines.

Why Choose Our Stainless Steel?

- Certified Quality: Third-party audited (ISO 9001, SGS) to ensure compliance with global standards.

- Custom Solutions: Tailored sizes, coatings, and packaging to meet project-specific needs.

- Competitive Pricing: Cost-effective without compromising on durability.

- Sustainable Practices: Eco-friendly manufacturing with minimal waste.

- Technical Support: 24/7 customer service for design and installation guidance.