StockSteel

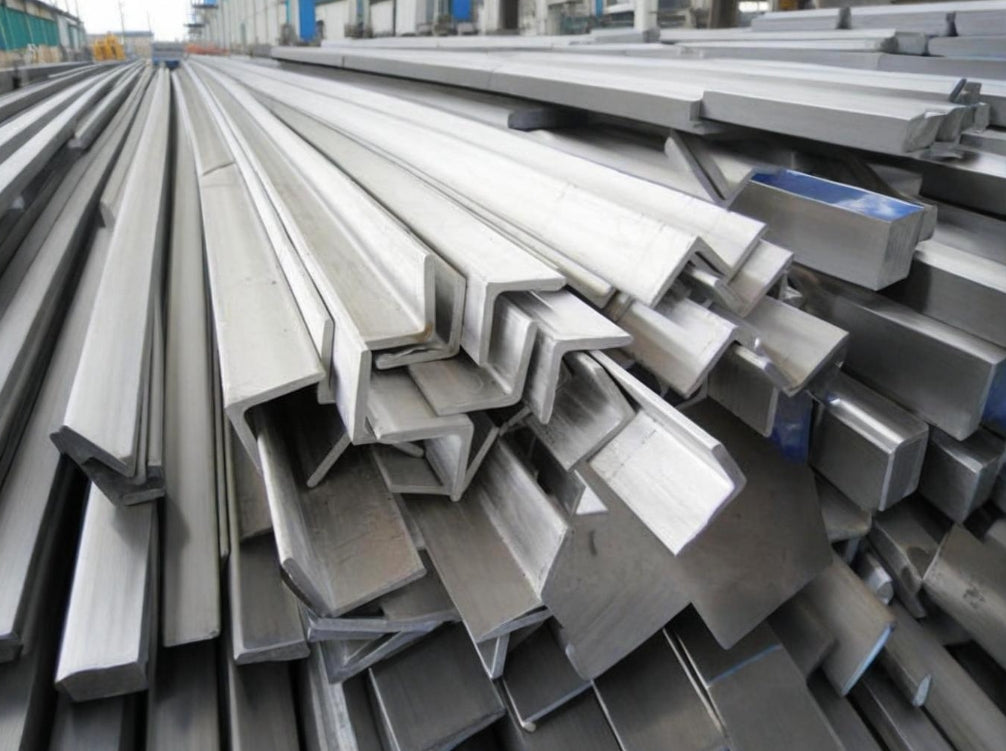

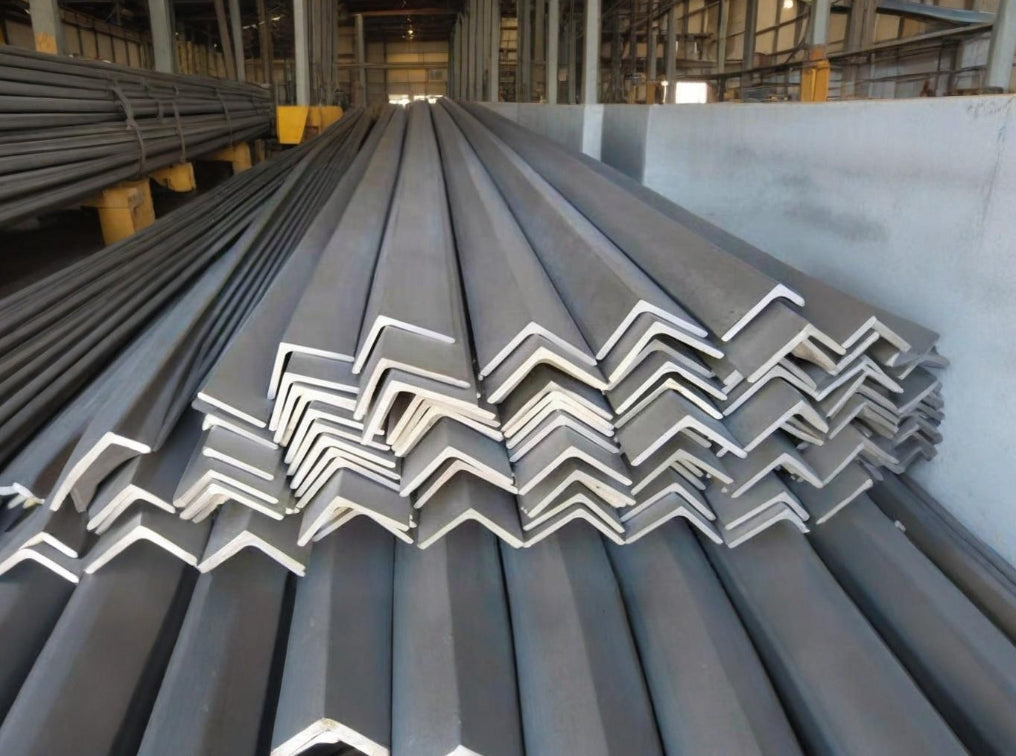

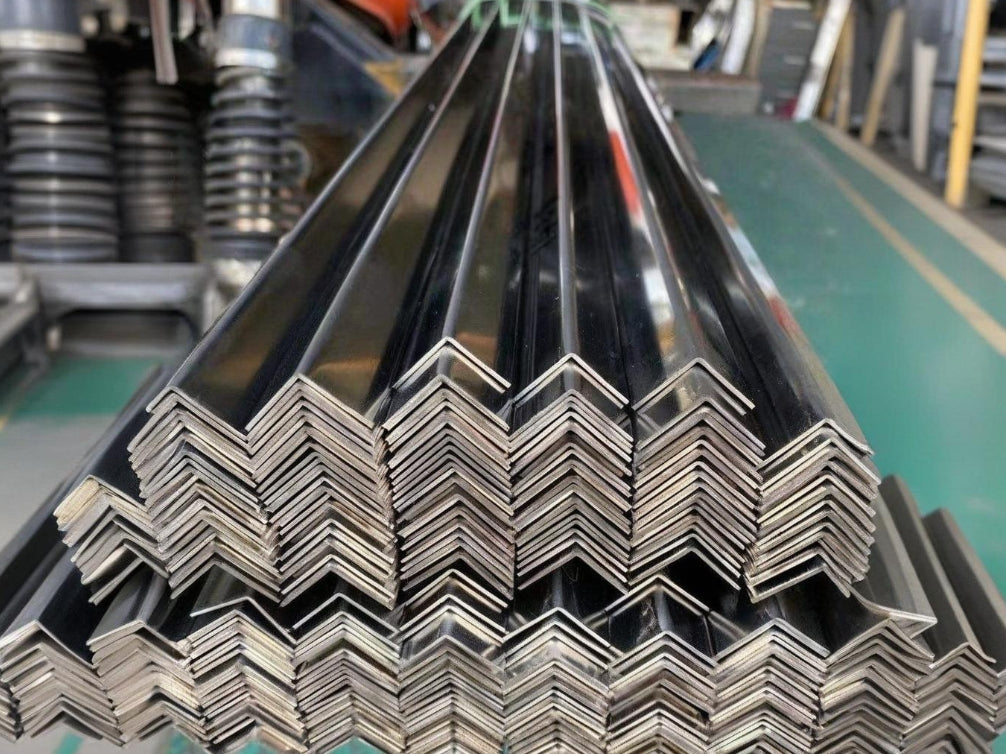

High-Strength Stainless Steel Angle | Industrial Framing

High-Strength Stainless Steel Angle | Industrial Framing

Couldn't load pickup availability

High-Strength Stainless Steel Angle | Industrial Framing

Product Specifications

| Property | AISI 304/304L | AISI 316/316L | AISI 201/321 |

|---|---|---|---|

| Dimensions | 20x20mm – 150x150mm | 25x25mm – 200x200mm | 15x15mm – 100x100mm |

| Thickness | 3mm – 20mm | 4mm – 25mm | 2mm – 12mm |

| Hardness | 1/2 Hard (HRB 85–95) | Annealed (HRB 70–85) | Full Hard (HRB ≥95) |

| Surface Finish | Hot Rolled, Pickled, Polished | Cold Rolled, Brushed | Mirror Finish, Hairline |

| Tensile Strength | 515–720 MPa | 520–690 MPa | 700–860 MPa |

| Yield Strength | 205–310 MPa | 215–290 MPa | 260–450 MPa |

| Elongation | 35%–45% | 40%–50% | 30%–40% |

| Applications | Stainless steel angle steel frameworks, stainless steel angle trim for architecture | Marine structures, chemical piping supports | High-temperature industrial equipment, exhaust systems |

Technical Performance & Features

Tensile & Bend Strength

Our stainless steel angle ASTM A276 products are engineered to withstand extreme mechanical stress. For instance, AISI 304L angles achieve tensile strengths of 515–720 MPa, ideal for stainless steel angle steel frameworks in construction. The high nickel content in AISI 316L enhances ductility (40–50% elongation), allowing seamless bending for custom stainless steel angle trim designs without cracking.

Weight Calculation

Calculate the weight of a stainless steel angle ASTM A276 using:

Weight (kg/m) = (Side1 + Side2 – Thickness) × Thickness × 0.00793

For a 50x50x5mm angle:

Weight = (50 + 50 – 5) × 5 × 0.00793 = 3.77 kg/m

Why Stainless Steel Angles Rust

Even premium grades like AISI 316L can corrode under specific conditions:

- Intergranular Corrosion: Poor welding practices or prolonged exposure to 450–850°C temperatures degrade chromium-carbide boundaries.

- Pitting in Chlorides: Saltwater or bleach splashes penetrate passive layers, causing localized pits.

- Galvanic Coupling: Direct contact with carbon steel or copper accelerates oxidation.

Our angles undergo solution annealing (AISI 304/316L) and electropolishing to minimize these risks, validated by ASTM A262 Practice E testing.

Identification & Marking

Each stainless steel angle ASTM A276 is stamped with:

- Grade (e.g., 304L, 316L)

- Heat Number (for traceability)

- ASTM A276 Compliance Mark

QR codes link to TISCO mill test certificates, including chemical composition and mechanical test results.

Compatibility & Usage

- Stainless steel angle steel: Designed for structural frameworks in warehouses, bridges, and conveyor systems. Compatible with MIG/TIG welding and bolt-fastening.

- Stainless steel angle trim: Precision-polished edges (Ra ≤0.4μm) for architectural cladding, elevator interiors, and hygienic food processing facilities.

Why Choose Our Stainless Steel Angles?

- Certified Material Quality:

- Direct sourcing from TISCO mills, ensuring compliance with ASTM A276 and EN 10088-2 standards.

- Batch-specific test reports for tensile strength, hardness, and intergranular corrosion resistance.

- Customization Capabilities:

- Laser-cutting services for unequal angles (e.g., 100x50mm) and non-standard thicknesses (2–25mm).

- Passivation or powder coating (RAL colors) for enhanced stainless steel angle trim aesthetics.

- Global Logistics:

- Export-ready packaging (wooden crates/VCI film) with 30-day corrosion protection.

- MOQ from 1 ton for small projects, with FOB/CIF terms for海运或空运.

- Technical Support:

- Free CAD models and load-bearing calculations for stainless steel angle steel frameworks.

- On-site welding guidance via certified metallurgists.

- Sustainability:

- 100% recyclable materials with ISO 14001-certified production.