StockSteel

High-Tensile Tin Roofing Sheets | SGCC & DX51D Standards

High-Tensile Tin Roofing Sheets | SGCC & DX51D Standards

Couldn't load pickup availability

High-Tensile Tin Roofing Sheets | SGCC & DX51D Standards

Product Overview

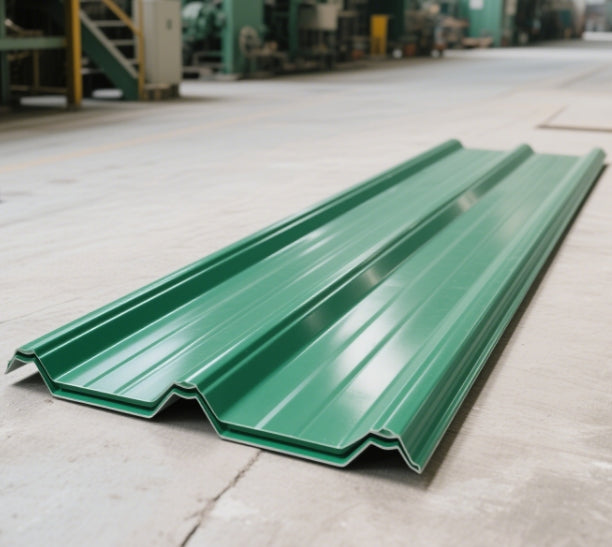

Our corrugated metal roof sheets and galvanised roof sheets are engineered for superior performance in industrial, commercial, and residential applications. Combining advanced metallurgical design with precision manufacturing, these sheets meet SGCC (JIS G3302) and DX51D (EN 10346) standards, ensuring exceptional strength, corrosion resistance, and longevity. Available in galvanized, pre-painted, and stone-coated variants, they are optimized for structural integrity and aesthetic versatility.

Technical Specifications

Certified to ASTM, EN, JIS, and ISO 9001/14001 standards.

| Parameter | Details |

|---|---|

| Material Grades | SGCC, DX51D, SGLCC (Galvalume), SPCC |

| Thickness | 0.12–2.0 mm (Customizable for corrugated metal roof sheets and galvanised roof sheets) |

| Width | 600–1250 mm (Post-corrugation: 665–900 mm) |

| Zinc Coating | 30–275 g/m² (Z60–Z275), spangle options: regular, minimized, zero |

| Surface Treatment | Hot-dip galvanized, chromated, PVDF/PE-coated, anti-fingerprint finish |

| Temper | Soft, half-hard, full-hard (HR30T: 45–70) |

| Corrugation Profile | Trapezoidal, IBR, arc, 9/11/14 wave designs |

| MOQ | 5 tons |

Performance Attributes

Tensile Strength

Our corrugated metal roof sheets achieve tensile strengths of 380–700 MPa (DX51D) and 550–620 MPa (SGCC), making them ideal for high-load environments such as industrial warehouses and hurricane-prone regions. The galvanised roof sheets utilize a dual-phase microstructure (ferrite and austenite) to balance ductility and rigidity, resisting deformation under wind loads exceeding 150 mph.

Bendability

Precision roll-forming technology enables bending radii as low as 1.2× thickness without cracking, critical for seamless installation of corrugated plastic roofing sheets and complex roof geometries. The cold-rolled edges ensure uniformity, reducing material waste during on-site adjustments.

Weight Calculation

- Galvanized Steel: 7.85 g/cm³ (e.g., 0.5 mm sheet = 3.93 kg/m²)

- Galvalume (Al-Zn): 7.2 g/cm³ (e.g., 0.6 mm sheet = 4.32 kg/m²)

- Corrugated Plastic: 1.2 g/cm³ (e.g., 3.0 mm sheet = 3.6 kg/m²)

Lightweight designs reduce structural support costs by 25–40% compared to concrete or asphalt alternatives.

Anti-Corrosion Mechanism

Galvanised roof sheets leverage zinc’s sacrificial protection to block rust formation, while corrugated metal roof sheets with Galvalume coatings (55% Al, 43.4% Zn, 1.6% Si) offer 4× longer lifespan than standard galvanized steel. For corrugated plastic roofing sheets, UV-stabilized polycarbonate or PVC layers prevent degradation under prolonged sun exposure.

Identification System

- Laser Marking: Batch codes (e.g., DX51D+AZ150) and compliance labels (EN 10346, ASTM A792).

- QR Tracking: Links to mill certificates, salt-spray test reports (1,000+ hours), and installation guidelines.

- Color Coding: Edge stripes denote thickness (e.g., red = 0.5 mm, blue = 0.8 mm).

Manufacturing Excellence

Process Flow

- Material Sourcing: Prime-grade steel coils from ISO-certified mills.

- Surface Prep:

- Galvanizing: Hot-dip immersion at 450°C, zinc coating control via air knives.

- Coating: PVDF, SMP, or HDP layers applied via reverse-roll coater (5–25 µm thickness).

- Corrugation: 26-stage hydraulic press forms trapezoidal/arc profiles (wave height: 15–40 mm).

- Quality Assurance: Eddy-current testing for coating uniformity; bend tests per ASTM A370.

Customization Options

- Profiles: Trapezoidal, double-layer, glazed tile, solar-ready brackets.

- Colors: 200+ RAL shades with 20-year fade warranty.

- Pre-Drilled Holes: For fast installation with stainless steel fasteners.

Why Choose Our Stainless Steel Roofing Sheets?

- Unmatched Durability: Chromium-nickel alloys (304/316) resist pitting in chloride-rich environments, outperforming carbon steel by 5× lifespan.

- Fire Resistance: Class A fire rating (melting point: 1,400°C) and UL 580 wind uplift certification.

- Sustainability: 100% recyclable with 60% recycled content; reduces HVAC loads via solar reflectance (SRI > 82).

- Aesthetic Flexibility: Matte, stone-coated, or embossed finishes for modern architectural designs.

- Global Compliance: Meets EN 10143, Miami-Dade HVHZ codes, and seismic zone requirements.