StockSteel

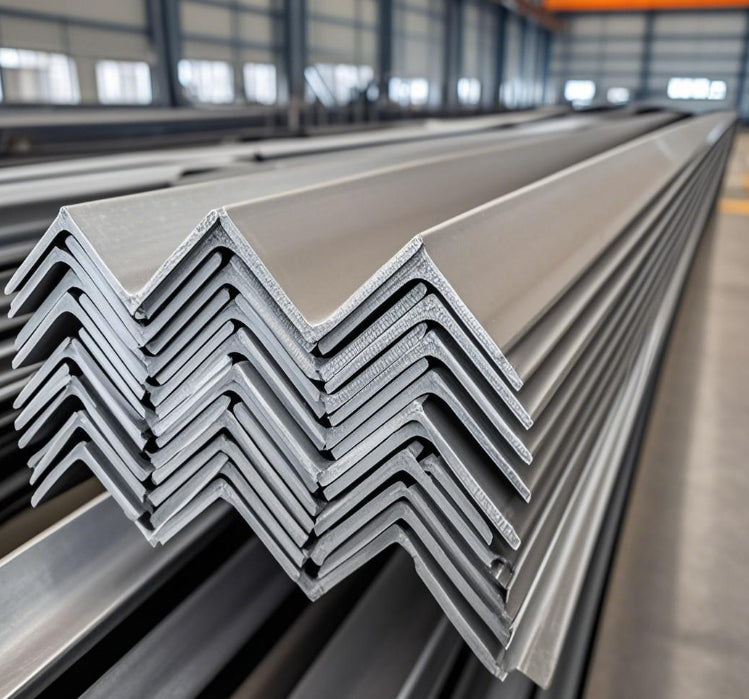

Industrial-Grade Stainless Angle Steel | ASTM A479 316L

Industrial-Grade Stainless Angle Steel | ASTM A479 316L

Regular price

$600.00 SGD

Regular price

Sale price

$600.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Industrial-Grade Stainless Angle Steel | ASTM A479 316L

Premium Structural Solutions for Marine, Chemical & Architectural Applications

Product Specifications

| Attribute | Details |

|---|---|

| Material Standard | Stainless angle steel: ASTM A479 316L / A276 (dual certification)

1

|

| Dimensions | Leg Length: 30×30×3mm to 150×150×12mm |

| Hardness (Rockwell) | HRB 85–95 (cold-worked) |

| Surface Finish | No. 4 brushed, mirror polish (No. 8), or sandblasted for enhanced aesthetics and corrosion resistance |

| Processing | Laser cutting, hot rolling, CNC bending for angle iron stainless steel projects |

| Certifications | ASTM A479/A276, ISO 9001, PED 2014/68/EU, NACE MR0175 |

Mechanical Properties

-

Tensile Strength:

- ASTM A479 316L: 515–690 MPa (75,000–100,000 psi)

. - Exceeds standard structural requirements for offshore platforms, chemical reactors, and coastal infrastructure.

- ASTM A479 316L: 515–690 MPa (75,000–100,000 psi)

-

Bending Strength:

- Achieves a 1:1 bend ratio (e.g., 50×50×6mm leg bends to 50mm radius) without cracking due to high ductility.

-

Yield Strength:

- Minimum 205 MPa (30,000 psi) in annealed conditions, adaptable to cold-working for increased rigidity

.

- Minimum 205 MPa (30,000 psi) in annealed conditions, adaptable to cold-working for increased rigidity

Technical Features

-

Weight Calculation:

- Formula for Equal Legs:

Example: 60×60×8mm → . - Pre-calculated charts available for stainless steel angle ASTM A276 and custom angle iron stainless steel profiles.

- Formula for Equal Legs:

-

Marking & Traceability:

- Laser-etched labels include heat number, grade (316L), and compliance codes (ASTM A479/A276).

-

Corrosion Resistance:

- 316L contains 2.5–3% molybdenum, offering superior resistance to chlorides, sulfuric acid, and saltwater environments.

Why Stainless Steel May Corrode?

Although stainless angle steel is highly durable, specific conditions can lead to localized rust:

- Chloride Exposure:

- Coastal or de-icing salt environments may cause pitting if the passive chromium oxide layer is damaged.

- Galvanic Corrosion:

- Direct contact with carbon steel or copper alloys in humid settings accelerates oxidation.

- High-Temperature Oxidation:

- Prolonged exposure above 870°C (1600°F) degrades chromium’s protective properties.

- Mechanical Stress:

- Improper welding or bending without post-treatment (e.g., pickling) reduces corrosion resistance.

Prevention Measures:

- Apply electropolishing to restore the chromium layer post-fabrication.

- Use insulating spacers to prevent galvanic coupling.

Why Choose Our Stainless Angle Steel?

- Material Superiority:

- Prime-grade 316L billets with ±0.3% molybdenum tolerance for unmatched corrosion resistance.

- Customization:

- Tailor stainless steel angle ASTM A276 profiles (e.g., 45×45×5mm) with slotting or notching for rapid assembly.

- Global Compliance:

- Dual-certified ASTM A479/A316L and NACE MR0175 for oil/gas and marine applications.

- Local Stock Availability:

- Immediate access to angle iron stainless steel in 2-inch (50.8mm) and 3-inch (76.2mm) leg sizes across North America and Europe.

- Sustainability:

- 90% recycled content with eco-friendly packaging (PVC-free wraps, reusable wooden crates).