StockSteel

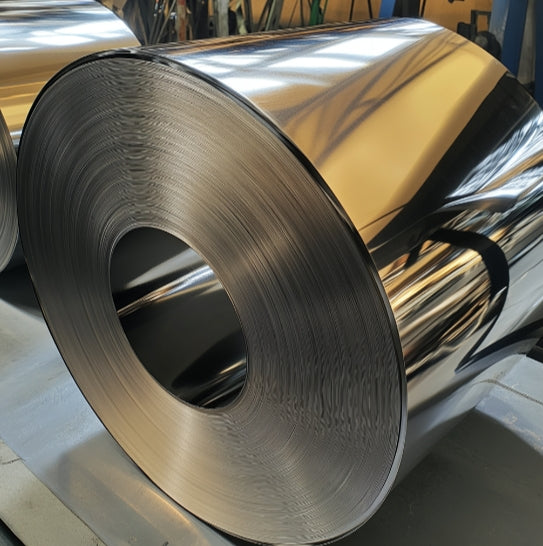

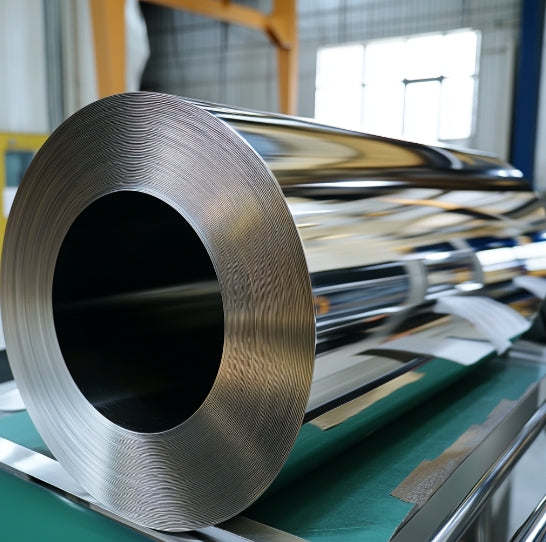

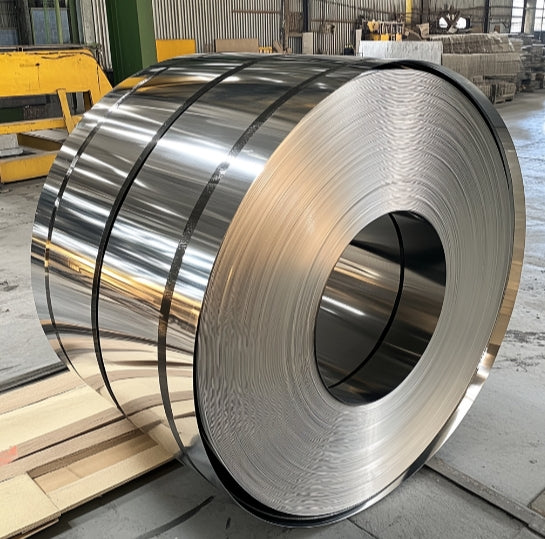

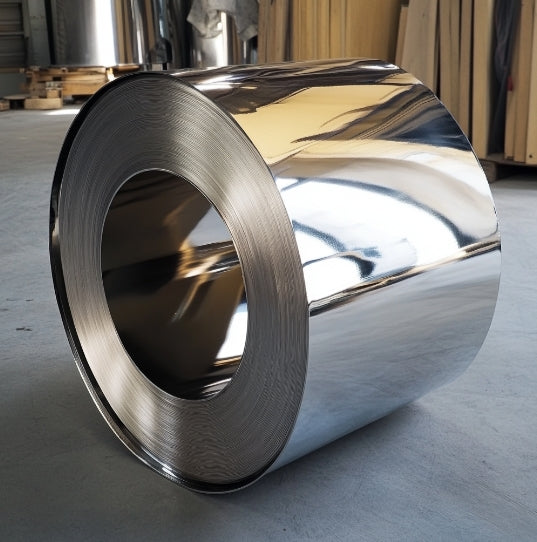

Industrial-Grade Stainless Steel Coil– Mirror Finish & Durable

Industrial-Grade Stainless Steel Coil– Mirror Finish & Durable

Couldn't load pickup availability

Grade 201/304/316/316L/430 Stainless Steel Product Details

Technical Specifications

Material Grades & Mechanical Properties

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HBW) | Elongation (%) | Surface Finish Options |

|---|---|---|---|---|---|

| 201 | 520–780 | ≥275 | ≤250 | ≥40 | Mirror, Hairline, 2B, BA |

| 304 | 515–1035 | ≥205 | ≤201 | ≥40 | Polished, No.4, 8K Mirror |

| 316 | 515–690 | ≥170 | ≤217 | ≥40 | Cold Rolled, 2B, Hairline |

| 316L | 485–620 | ≥170 | ≤187 | ≥40 | Electrolytic Polished, Satin |

| 430 | 450–600 | ≥206 | ≤183 | ≥22 | Bead Blasted, Titanium Coated |

Dimensions & Processing

| Thickness (mm) | Width (mm) | Length (mm) | Edge Type | Tolerance | Key Applications |

|---|---|---|---|---|---|

| 0.1–3 (Cold) | 600–2000 | 2000–12000 | Slit, Mill | ±0.02–0.1mm | Stainless Steel Coil stock, Architectural Panels |

| 3–100 (Hot) | 1000–2150 | 6000–12000 | Sheared | ±1%–3% | Stainless steel tubing coils, Industrial Tanks |

Extended Technical Insights

Tensile & Bending Strength

Grade 304 exhibits a tensile strength range of 515–1035 MPa, ideal for structural components like beams and chemical tanks. Its cold-rolled variants achieve higher strength through work hardening, while Grade 316L (485–620 MPa) prioritizes corrosion resistance in chloride-rich environments like marine applications. For stainless steel heating coils, post-rolling annealing ensures ductility while maintaining thermal stability.

Bending strength correlates with material ductility. Austenitic grades (304/316) allow 180° bends without cracking, whereas ferritic Grade 430 requires controlled forming to avoid brittleness.

Identification Methods

- Chemical Analysis: XRF testing verifies chromium (≥10.5%), nickel (8–12% for 304), and molybdenum (2–3% for 316).

- Magnetism: Austenitic grades (304/316) are non-magnetic; slight magnetism may occur after cold working.

- Surface Marking: Laser-etched labels (e.g., "ASTM A240") or color-coded edges for traceability.

Weight Calculation Formula

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93 g/cm³ for 304/316; 7.75 g/cm³ for 430).

Example: A 2mm × 1m × 2m Stainless Steel Coil stock weighs:

2 × 1 × 2 × 7.93 = 31.72 kg.

Why Does Stainless Steel Rust?

Despite its corrosion resistance, rust can occur under:

- Chloride Exposure: Coastal environments or de-icing salts accelerate pitting in 304 (vs. 316L's superior resistance).

- Surface Contamination: Organic residues (grease, iron particles) create galvanic cells, breaching the passive chromium oxide layer.

- Mechanical Damage: Scratches or weld zones reduce chromium concentration, weakening protection.

- Improper Cleaning: Harsh abrasives degrade finishes like Mirror or Hairline.

Why Choose Our Stainless Steel?

- Certified Quality: Compliance with ASTM, EN, JIS, and ISO 9001 standards, backed by third-party SGS inspections.

- Customization: Tailor thickness (0.01–100mm), width (up to 2150mm), and surface finishes (Polished, Hairline, PVD-coated).

- Rapid Delivery: 15,000+ tons of Stainless Steel Coil stock ready for immediate shipment, with 7–15-day global logistics.

- Versatility: Optimized for stainless steel heating coils (high-temperature stability) and stainless steel tubing coils (pressure resistance).

- Sustainability: 100% recyclable materials align with eco-friendly manufacturing practices.