StockSteel

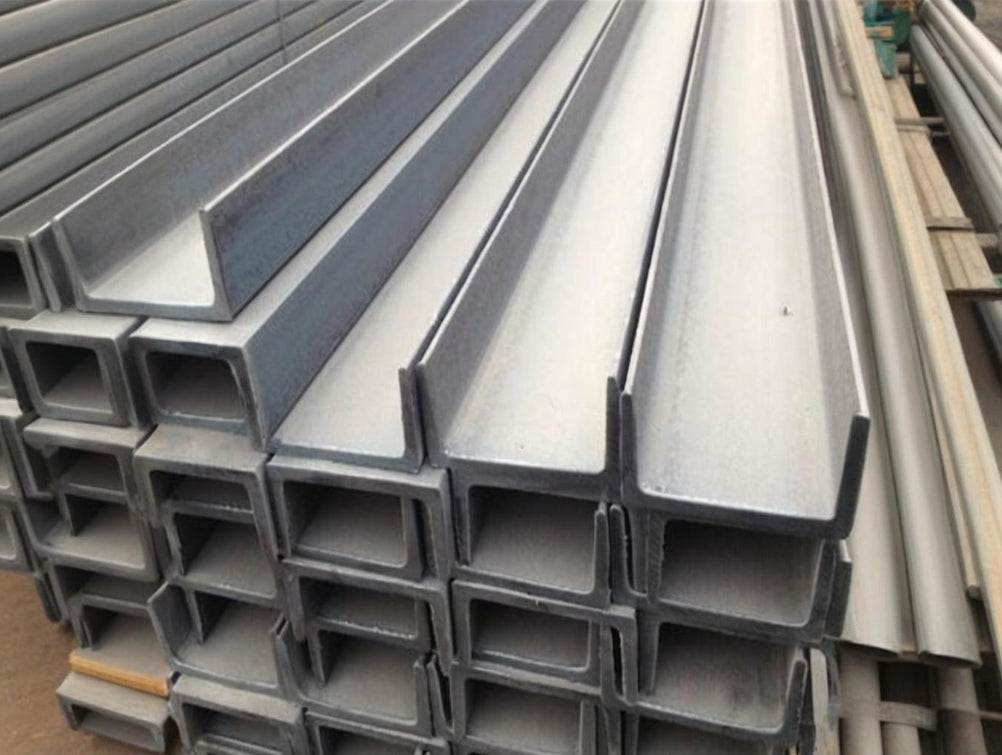

Industrial-Grade Stainless Steel U Channel | Customizable & Durable

Industrial-Grade Stainless Steel U Channel | Customizable & Durable

Couldn't load pickup availability

Industrial-Grade Stainless Steel U Channel | Customizable & Durable

Product Specifications

| Property | Details |

|---|---|

| Material Grade | Stainless Steel U Channel: 304, 316, 201 (ASTM A554, EN 1.4301/1.4401) |

| Hardness (Rockwell B) | 304: 70-90 HRB 316: 75-95 HRB 201: 85-100 HRB |

| Dimensions | Web Width: 50–320 mm Flange Width: 37–88 mm Thickness: 4.5–9.5 mm |

| Standard Length | 6–12 meters (custom cuts up to 20 meters available) |

| Surface Finish | Mill Finish, Brushed (No. 4), Mirror Polish, Electroplated (Optional) |

| Applications | Structural Frameworks, Stainless Steel C Channel Supports, Stainless Steel Channel Drain Systems, Industrial Machinery |

Key Technical Properties

Tensile Strength

Stainless steel U channel exhibits exceptional tensile strength, ranging from 520 MPa (304) to 860 MPa (316L). This ensures resistance to deformation under heavy loads, making it ideal for industrial frameworks and machinery supports. The high chromium (18–20%) and nickel (8–12%) content in 304/316 grades enhances ductility while maintaining structural integrity.

Bending Strength

Designed to withstand lateral forces, stainless steel U channel achieves bending strengths of 180–350 MPa depending on alloy composition. Its symmetrical geometry distributes stress evenly, preventing fractures in applications like conveyor systems or stainless steel channel drain installations.

Identification & Marking

Stainless steel channels follow global standards:

- ASTM A554: Laser-etched labels for grade (e.g., 304, 316) and batch number.

- EN Standards: Chemical composition markings (e.g., 1.4301 for 304).

- JIS Codes: Embossed symbols indicating thickness tolerance (e.g., SUS304).

Weight Calculation Formula

Calculate weight (kg/m) for stainless steel U channel:

Example: A 304-grade U channel (6m length, 100mm width, 5mm thickness) weighs:

Why Stainless Steel Rusts?

While stainless steel U channel is corrosion-resistant, rust may occur under extreme conditions:

- Chloride Exposure: Coastal or industrial environments with high salinity degrade the chromium oxide layer, leading to pitting.

- Mechanical Damage: Scratches or abrasions expose raw metal to oxygen and moisture, triggering oxidation.

- Low-Quality Alloys: Substandard grades (e.g., 201 with <10.5% chromium) lack sufficient corrosion resistance.

- Electrochemical Reactions: Contact with carbon steel or iron debris creates galvanic corrosion.

Prevention Tips:

- Use 316-grade for coastal areas (molybdenum enhances chloride resistance).

- Apply protective coatings (e.g., PVDF) on stainless steel channel drain systems.

- Clean surfaces regularly to remove contaminants.

Why Choose Our Stainless Steel U Channels?

- Superior Durability: Our 304/316 grades exceed ASTM standards, with a lifespan exceeding 30 years in harsh environments.

- Customization: Tailor dimensions, finishes, and packaging to your project needs.

- Eco-Friendly: 100% recyclable material with zero formaldehyde or VOC emissions, ideal for stainless steel c channel supports in green buildings.

- Certified Quality: Third-party tested for chemical composition, hardness, and load capacity.

- Global Logistics: Fast shipping with anti-corrosion packaging for international orders.