StockSteel

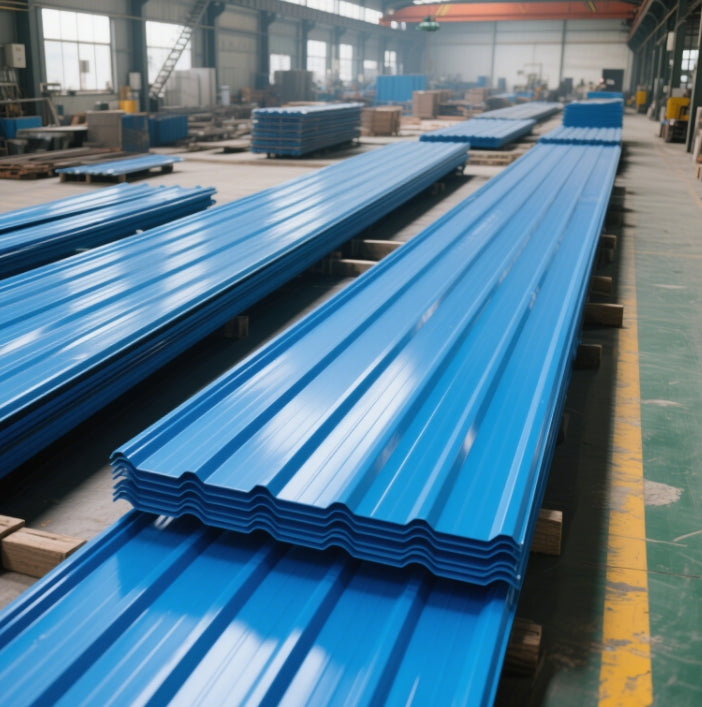

Industrial-Grade Tin Roofing Sheets | Prepainted for Durability

Industrial-Grade Tin Roofing Sheets | Prepainted for Durability

Couldn't load pickup availability

Industrial-Grade Tin Roofing Sheets | Prepainted for Durability

Product Overview

Our corrugated roof sheets are engineered for industrial applications, combining superior strength, corrosion resistance, and aesthetic appeal. Made from galvanized roofing sheets with a prepainted finish, these sheets ensure long-term durability in harsh environments. Whether used for warehouses, factories, or residential projects, our metal roofing sheets near me offer unmatched performance and ease of installation.

Specifications

| Parameter | Details |

|---|---|

| Material | Galvanized Steel (SPCC/SGCC), Aluzinc, Pre-painted Coating |

| Thickness | 0.14–1.5 mm (customizable) |

| Width | 600–1250 mm |

| Length | Up to 12 meters |

| Surface Finish | Stone-coated, Color Coated (RAL/Pantone options), Bright/Matt Finish |

| Coating Type | Hot-dip Galvanized (50–180 g/m²), Aluzinc (AZ150) |

| Corrugation Profile | Rectangular, Trapezoidal, Double Roman Tile, Custom Designs |

| Tensile Strength | 230–620 MPa (depending on grade) |

| Hardness (HR30T) | T2 (52+3), T3 (57+3), T5 (65+3) |

| MOQ | 5 Tons (custom orders accepted) |

Key Attributes

-

Durability:

- Galvanized roofing sheets provide exceptional resistance to rust and corrosion, even in coastal or high-humidity environments.

- Prepainted layers offer UV protection, ensuring color retention for over 20 years.

-

Structural Performance:

- Tensile Strength: Ranges from 230 MPa (TS230) to 620 MPa (TS620), suitable for high-load applications like industrial roofing.

- Bending Strength: Designed to withstand wind loads up to 150 km/h and heavy snow accumulation.

-

Lightweight & Easy Installation:

- Weighs only 3–7.5 kg/m², reducing structural load compared to concrete or clay tiles.

- Pre-punched holes and standardized profiles simplify on-site assembly.

Technical Details

Tensile & Bending Strength

Our corrugated roof sheets undergo rigorous testing to meet international standards (ASTM, JIS, DIN). The tensile strength is optimized through cold-rolled processing, ensuring uniformity and resistance to deformation. For bending, the trapezoidal rib design enhances rigidity, preventing sagging even under prolonged stress.

Weight Calculation

Use the formula below to estimate sheet weight:

Example: A 10m × 1.2m sheet at 0.5mm thickness weighs .

Identification & Marking

Each sheet is laser-etched with:

- Grade (e.g., TS275, AZ150)

- Coating type (Galvanized/Aluzinc)

- Batch number for traceability.

Why Stainless Steel Can Rust?

While stainless steel is corrosion-resistant, improper handling or environmental factors can cause rust:

- Electrochemical Corrosion: Contaminants (e.g., iron dust) create micro-batteries in humid conditions, breaking the protective chromium oxide layer.

- Chemical Exposure: Acids, alkalis, or saline solutions (common in industrial areas) degrade the surface over time.

- Mechanical Damage: Scratches or abrasions expose the underlying steel to oxygen, leading to oxidation.

To mitigate rust:

- Regularly clean surfaces with pH-neutral solutions.

- Use galvanized roofing sheets with thicker zinc coatings (≥180 g/m²) for corrosive environments.

Why Choose Our Stainless Steel?

-

Superior Material Quality:

- Alloy composition (18% Cr, 8–10% Ni) exceeds ASTM standards, ensuring longevity.

- Advanced cold-rolling technology enhances surface uniformity and strength.

-

Certifications & Compliance:

- ISO 9001, RoHS, and IBR certifications guarantee environmental and safety compliance.

-

Custom Solutions:

- Tailored profiles, colors, and thicknesses to meet project-specific needs.

-

Global Reliability:

- Trusted by infrastructure projects worldwide, from solar farms to high-rise buildings.