StockSteel

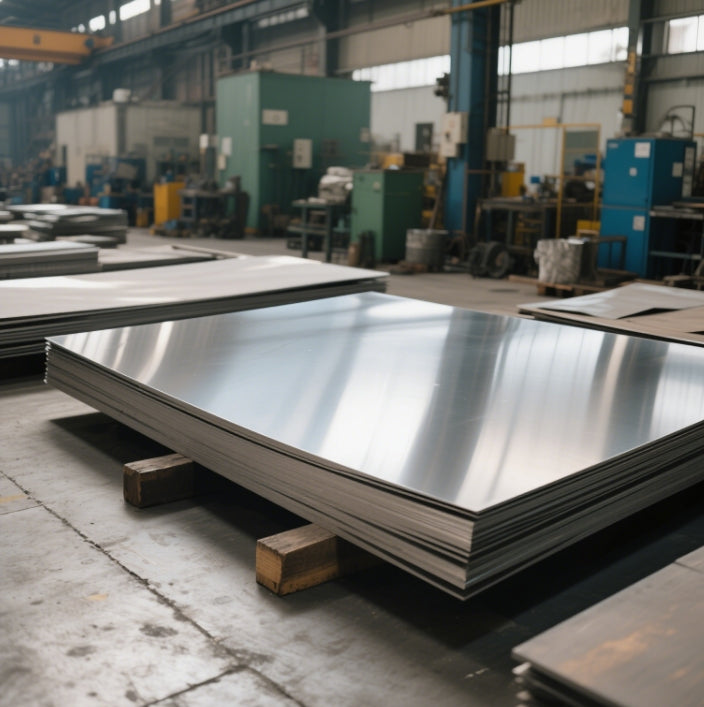

Industrial-Strength plate stainless steel | Diamond Grids for Heavy-Duty Workshops

Industrial-Strength plate stainless steel | Diamond Grids for Heavy-Duty Workshops

Couldn't load pickup availability

Industrial-Strength Stainless Steel Plate | Diamond Grids for Heavy-Duty Workshops

Product Specifications

| Attribute | Details |

|---|---|

| Material Grade | 316 stainless steel plates (ASTM A240/A480, EN 1.4401), 2205 Duplex |

| Thickness | 3mm – 50mm (Customizable) |

| Width | 1000mm – 2500mm |

| Length | 2000mm – 6000mm |

| Surface Finish | Diamond Anti-Slip Grid, Black Ion Plated Stainless Steel, Brushed (No.4) |

| Hardness | HRB 85-100 (Annealed), HRC 25-40 (Cold Rolled) |

| Density | 7.93–8.0 g/cm³ (Grade 316: 7.99 g/cm³) |

| Processing | Hot Rolling, Laser Cutting, CNC Machining, Diamond Grid Pressing |

Key Features & Benefits

-

Unmatched Durability

Engineered for industrial workshops, our best stainless steel plates combine high tensile strength (580–930 MPa) with diamond grid patterns to resist wear, impact, and heavy loads. Ideal for factory floors, mezzanines, and machinery platforms. -

Corrosion Resistance

316 stainless steel plates (2-3% Mo) excel in harsh environments like chemical plants and marine workshops, outperforming carbon steel and lower-grade stainless steels. -

Safety & Functionality

Diamond grids provide anti-slip properties (R13+ rating) and debris drainage, while black ion plated stainless steel finishes reduce glare and enhance aesthetics. -

Custom Fabrication

Precision-cut for stair treads, catwalks, or conveyor bases. Compatible with welding, bolting, and modular assembly.

Technical Details

1. Tensile Strength

Tensile strength defines the maximum stress a material can endure before fracture. Our plates are tested per ASTM E8 standards:

- 316 Stainless Steel: 580–860 MPa (ideal for saltwater and chemical exposure).

- 2205 Duplex: 620–930 MPa (dual-phase structure for extreme load-bearing).

- Diamond Grid Plates: Enhanced rigidity reduces deflection under heavy machinery (up to 5 tons/m²).

2. Bend Strength

Bend strength ensures flexibility without cracking. Tested via ASTM E290 three-point bending:

- Cold-Rolled Plates: Achieve 180° bends for curved platforms or machinery guards.

- Diamond Grid Integration: Press-formed grids maintain structural integrity even after deformation.

3. Identification & Marking

- Laser Etching: Permanent grade markings (e.g., "316L," "2205") for traceability.

- Heat Numbers: Unique batch codes linked to mill test certificates (MTCs).

- QR Codes: Scan for real-time material certifications and installation guides.

4. Weight Calculation

Formula:

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93–8.0)

Example: A 10mm × 1.5m × 3m 316 stainless steel plate weighs 357.3 kg.

5. Why Does Stainless Steel Rust?

Despite its corrosion resistance, rust can occur due to:

- Chloride Exposure: Saltwater or de-icing agents degrade the chromium oxide layer.

- Mechanical Damage: Scratches or welding defects expose the base metal to oxidation.

- Galvanic Corrosion: Contact with carbon steel or dissimilar metals (e.g., black ion plated stainless steel with aluminum).

- Low-Quality Alloys: Substandard chromium/molybdenum content in cheaper grades.

Applications

| Industry | Use Cases |

|---|---|

| Manufacturing | Heavy machinery platforms, robotic cell flooring, forklift pathways |

| Energy & Marine | Offshore rig walkways, ship engine room grids, oil refinery stair treads |

| Transportation | Cargo truck beds, railway maintenance platforms, airport hangar floors |

| Construction | Mezzanine flooring, scaffolding boards, bridge access panels |

Why Choose Our Stainless Steel Plates?

- Certified Excellence: Compliant with ASTM, EN, ISO, and DNV/GL standards for industrial safety.

- Sustainable Practices: 70% recycled content, zero VOC emissions, and 100% recyclable.

- Custom Solutions: Tailored diamond grid patterns, black ion plated stainless steel finishes, and rapid prototyping.

- Global Logistics: 15-day lead time with door-to-door shipping and customs clearance support.

- Lifetime Warranty: Guaranteed against structural defects and premature corrosion.