StockSteel

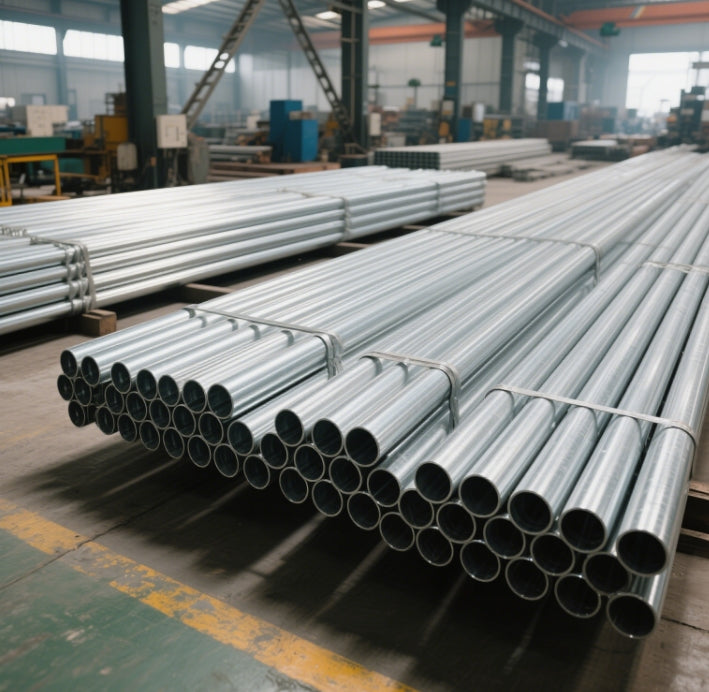

Lightweight galvanized pipe fittings | Easy-Handling Construction

Lightweight galvanized pipe fittings | Easy-Handling Construction

Couldn't load pickup availability

Lightweight Galvanized Pipe Fittings | Easy-Handling Construction

Product Overview

Lightweight galvanized pipe fittings are engineered for construction projects requiring effortless installation and corrosion resistance. Designed for HVAC systems, galvanized duct pipe networks, and structural frameworks, these fittings combine hot-dip galvanized durability with reduced weight for enhanced portability. Ideal for both indoor and outdoor applications, they ensure longevity in environments exposed to moisture, chemicals, and mechanical stress.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Carbon steel (ASTM A53) with hot-dip galvanized coating (≥80μm zinc) |

| Size Range | ½" to 12" (DN15–DN300) |

| Pressure Rating | 150–3000 PSI (ASME B16.11, ISO 4144) |

| Hardness | 120–180 HV (Vickers) |

| Surface Treatment | Hot-dip galvanized, passivated for enhanced corrosion resistance |

| Process | Cold forging, threading, precision machining, ISO-certified QC |

Key Features

1. Tensile & Bend Strength

Tensile strength (350–500 MPa) ensures resistance to internal pressure and structural loads, critical for galvanized corrugated metal pipe systems in drainage and culvert projects. Bend strength (250–400 MPa) prevents deformation under lateral forces, maintaining alignment in curved installations like HVAC ductwork.

2. Identification & Marking

Fittings are laser-etched with ASTM standards (e.g., A123, A53), size, and batch numbers for traceability. Galvanized pipe cap components include embossed pressure ratings to simplify compliance checks during inspections.

3. Weight Calculation

Weight (kg/m) = (OD² – (OD – 2×WT)²) × 0.02466

Example: For a 3" (88.9mm OD) pipe with 3mm wall thickness:

(88.9² – 82.9²) × 0.02466 ≈ 6.22 kg/m.

4. Why Stainless Steel Can Rust

Although stainless steel resists corrosion, chloride exposure (e.g., coastal air or road salts), mechanical abrasion, or high-temperature oxidation can degrade its passive chromium oxide layer. For example, in coastal construction, salt-laden moisture accelerates pitting corrosion in stainless steel joints.

Installation & Application Insights

Galvanized Corrugated Metal Pipe

Ideal for culverts and stormwater management, these pipes feature spiral ribs for enhanced hydraulic efficiency. Use rubber gaskets and stainless steel clamps to ensure leak-proof connections in underground installations.

Galvanized Duct Pipe

Optimized for HVAC systems, these pipes reduce airflow resistance with smooth interiors. Seal joints using PTFE tape or silicone sealant to prevent air leakage. For fire-rated ducts, pair with intumescent collars.

Galvanized Pipe Cap

Protect pipe ends from debris and moisture during storage or transit. Caps are compatible with threaded, welded, or clamped systems. Apply zinc-rich paint post-installation to maintain corrosion resistance at exposed edges.

Why Choose Our Stainless Steel Solutions?

-

Superior Corrosion Resistance

Our 304/316L stainless steel fittings outperform galvanized options in chloride-rich environments (e.g., coastal HVAC systems or chemical plants). The chromium-nickel alloy forms a self-repairing oxide layer, eliminating the need for recoating. -

Eco-Friendly & Recyclable

Stainless steel is 100% recyclable, reducing landfill waste and aligning with LEED-certified projects. Its 50+ year lifespan minimizes replacement frequency. -

Hygienic & Low Maintenance

Non-porous surfaces prevent bacterial growth, making it ideal for water supply and food processing facilities. Requires no chemical cleaners—simple rinsing maintains hygiene. -

Certified Compliance

All products meet ISO 9001, ASTM A312, and EN 10217-7 standards. Third-party tested for pressure integrity and material composition. -

Customization

Tailor-made solutions for non-standard sizes, alloy grades (e.g., duplex steel for extreme temperatures), and industry-specific certifications.