StockSteel

Lightweight stainless steel plate | Perfect for Automotive & DIY Projects

Lightweight stainless steel plate | Perfect for Automotive & DIY Projects

Couldn't load pickup availability

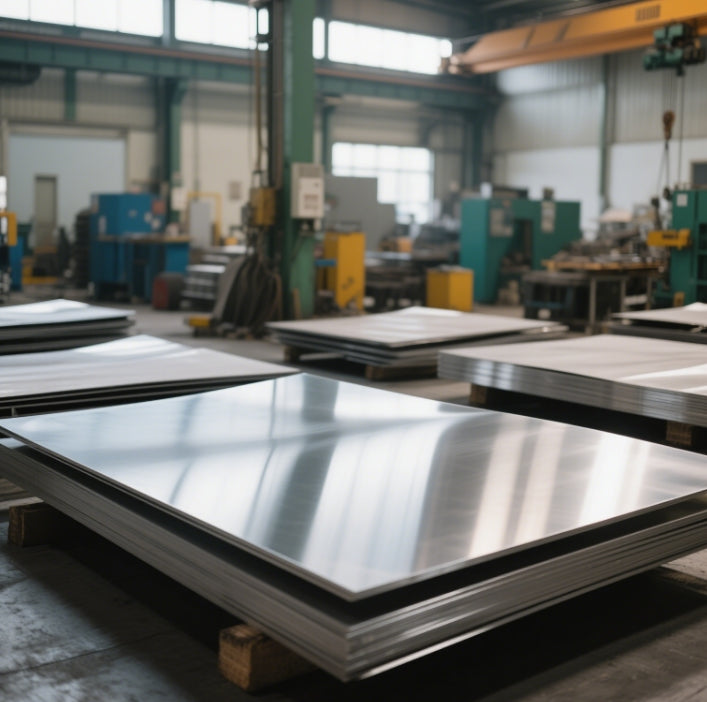

Lightweight Stainless Steel Plate | Perfect for Automotive & DIY Projects

Discover the ultimate solution for precision engineering and creative craftsmanship with our lightweight stainless steel plates, engineered for durability and versatility. Ideal for automotive parts, custom DIY projects, and industrial applications, our plates combine superior strength with unmatched corrosion resistance.

Product Specifications

| Property | Value |

|---|---|

| Grade | ASTM A240 304/304L, 316/316L, 430 |

| Thickness | 0.3 mm – 6 mm (Customizable) |

| Width | 1000 mm – 1500 mm |

| Length | 2000 mm – 6000 mm |

| Hardness | ≤187 HBW (304); ≤217 HBW (430) |

| Surface Finish | 2B, BA, No.4, Hairline, Embossed |

| Density | 7.93 g/cm³ (304); 7.70 g/cm³ (430) |

| Thermal Conductivity | 16.2 W/m·K (304); 26 W/m·K (430) |

Mechanical & Functional Properties

Tensile Strength

Our lightweight stainless steel plates deliver exceptional tensile strength ranging from 520 MPa (304) to 650 MPa (430), ensuring structural integrity under high-stress conditions. This makes them ideal for automotive components like stainless steel kick plates and load-bearing parts requiring resistance to deformation. The yield strength of ≥205 MPa (304) guarantees stability in dynamic applications, such as chassis reinforcements or custom stainless steel cover plates for machinery.

Bending Strength

With elongation rates up to 45% (304) and 22% (430), these plates withstand complex forming processes without cracking. This flexibility is critical for creating curved designs, such as stainless steel chip and dip plate molds or decorative automotive trims.

Material Identification & Standards

Key Designations

- ASTM A240: Specifies chromium-nickel grades (304/316) and chromium grades (430) for corrosion resistance.

- EN 1.4301/1.4016: European standards equivalent to 304 and 430, ensuring global compatibility.

- JIS SUS304/SUS430: Japanese industrial standards for automotive and architectural use.

Why Compliance Matters

Strict adherence to these standards guarantees optimal chromium content (18–20% in 304; 16–18% in 430) and controlled carbon levels (≤0.08%), enhancing weldability and rust resistance.

Weight Calculation

Calculate plate weight using the formula:

Example: A 1.5 mm × 1 m × 2 m 304 plate weighs:

Why Stainless Steel Corrodes?

Despite its resilience, stainless steel may rust under specific conditions:

- Chloride Exposure: Coastal environments or road salts accelerate pitting corrosion, particularly in grades like 430 with lower nickel content.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel) triggers electrochemical reactions.

- Surface Contamination: Iron particles from tools or abrasive cleaning disrupt the passive oxide layer.

- High-Temperature Oxidation: Prolonged exposure above 800°C (1472°F) degrades chromium’s protective effect.

Why Choose Our Stainless Steel Plates?

- Precision Engineering: Laser-cut edges and CNC-bent profiles for seamless integration into automotive or DIY projects.

- Custom Finishes: Choose from brushed (No.4), mirror-polished, or embossed textures to match aesthetic needs.

- Eco-Friendly: 100% recyclable material with low lifecycle carbon footprint.

- Technical Support: Free guidance on welding techniques, corrosion prevention, and design optimization.