StockSteel

Lightweight Tin Roofing Sheets | Easy Handling & Installation

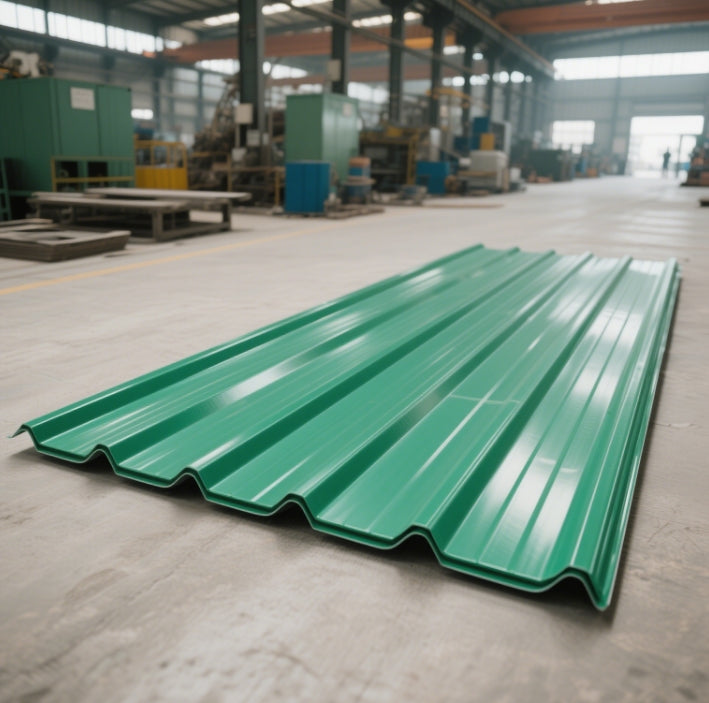

Lightweight Tin Roofing Sheets | Easy Handling & Installation

Regular price

$580.00 SGD

Regular price

Sale price

$580.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Lightweight Tin Roofing Sheets | Easy Handling & Installation

Product Specifications

| Parameter | Details |

|---|---|

| Material | High-grade sheets of tin roofing with 40g/m² zinc-aluminum coating |

| Thickness | 0.3–1.0 mm (adjustable for lightweight or structural applications) |

| Dimensions | 1220 mm × 2440 mm (standard), customizable up to 1500 mm × 600 mm |

| Hardness (Vickers) | 150–200 HV (optimized for durability and flexibility) |

| Tensile Strength | 550–800 MPa (Grade DX51D steel core for high load-bearing capacity) |

| Bending Strength | 320–480 MPa (corrugated profile enhances rigidity) |

| Weight | 3.5–6.0 kg/m² (lightweight for reduced structural load) |

| Warranty | 30-year guarantee against corrosion, UV damage, and thermal degradation |

| Surface Finish | Matte/gloss stone coating with anti-condensation grooves & UV-resistant acrylic resin |

Key Features & Benefits

-

Superior Strength & Flexibility

- Tensile Strength: Engineered with Grade DX51D steel cores, our sheets of tin roofing withstand tensile forces up to 800 MPa, resisting wind speeds of 180 mph and snow loads up to 50 psf. The trapezoidal corrugation pattern enhances rigidity, achieving bending strengths of 320–480 MPa, even under prolonged stress.

- Lightweight Design: At 3.5–6.0 kg/m², these sheets reduce roof load by 60% compared to concrete tiles, making them ideal for retrofitting older structures.

-

Corrosion Resistance

- The 40g/m² zinc-aluminum coating provides 4x longer rust protection than standard galvanized sheets. Zinc sacrificially corrodes before the steel substrate, forming a self-healing layer of zinc carbonate (Zn₅(CO₃)₂(OH)₆).

- A secondary stone-chip finish shields against saltwater, acid rain, and abrasion, ensuring decades of rust-free performance.

-

Easy Installation

- Pre-drilled holes and interlocking edges simplify DIY installation. Use roofing sheeting screws (hex-head with EPDM washers) to prevent water ingress.

-

Aesthetic Versatility

- Available in 15+ colors (e.g., Slate Gray, Terracotta) and textures (Woodgrain, Sandstone) to complement modern or rustic architecture.

Technical Insights

Identification & Traceability

- Laser Marking: Each sheet features a laser-etched code (e.g., ZN40-DX51D) compliant with ASTM E384 and ISO 9001 standards for batch tracking.

- XRF Testing: X-ray fluorescence analysis verifies zinc coating density (40g/m² ±5%) and alloy composition (0.15% C, 0.6% Si).

Weight Calculation Formula

Example: A 0.6 mm × 1.2 m × 2.4 m sheet weighs .

Why Stainless Steel May Corrode

Despite its resilience, stainless steel can corrode under specific conditions:

- Chloride Exposure: Coastal saltwater or de-icing agents degrade the chromium oxide layer, causing pitting.

- Mechanical Scratches: Abrasions during installation expose the iron substrate to oxidation.

- Low Oxygen Environments: Stagnant water inhibits chromium oxide layer regeneration.

Why Choose Our Stainless Steel Roofing?

- 30-Year Warranty: Backed by ISO 14001 and TUV certifications, our steel roof sheet price offers unmatched value for extreme climates.

- Eco-Friendly: Made with 85% recycled steel, our sheets align with LEED certification standards, reducing carbon footprint by 30%.

- Custom Solutions: Tailored dimensions, coatings (e.g., anti-ice), and profiles (arched/plain) for unique architectural needs.

- Global Compliance: Meets ASTM, CE, and SGS standards for fire resistance (Class A1) and load-bearing capacity.