StockSteel

Low-Cost Tin Roofing Sheets | Factory Direct Pricing

Low-Cost Tin Roofing Sheets | Factory Direct Pricing

Couldn't load pickup availability

Low-Cost Tin Roofing Sheets | Factory Direct Pricing

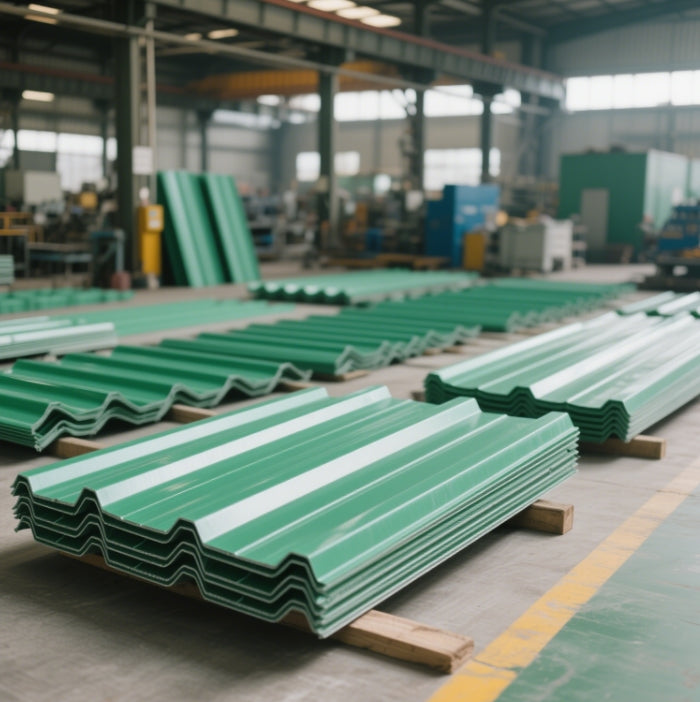

Product Overview

Our roof cap sheet and roofing metal sheet solutions are engineered for affordability without compromising durability. Manufactured from premium-grade tinplate and zinc-aluminum alloys, these roofing plastic sheets alternatives deliver exceptional corrosion resistance and structural integrity. Ideal for residential, agricultural, and light commercial projects, they combine cost efficiency with long-term performance in harsh climates.

Technical Specifications

| Attribute | Details |

|---|---|

| Material | Tinplate (SPTE) / Galvalume® alloy (55% Al, 43.4% Zn, 1.6% Si) |

| Hardness | TS230–TS620 (adjustable for seismic or high-wind regions) |

| Thickness | 0.14–0.6 mm (customizable to 0.18 mm for lightweight designs) |

| Width | 600–1250 mm (seamless overlap for leak-proof installation) |

| Surface Finish | Corrugated, Matte, Stone, Anti-Fingerprint (AFP), Custom Embossing |

| Coating | Dual-layer zinc-aluminum (30–275 g/m²) with chromate passivation |

| Temper | T1-T5, DR7-DR9 (optimized for load-bearing up to 150 kg/m²) |

| Certifications | ASTM A623, ISO 9001, SGS, EN 10143 |

Performance Characteristics

1. Tensile & Bend Strength

Our roofing metal sheet achieves tensile strengths of 260–620 MPa through precision cold-rolling and annealing processes. Validated by ASTM A789 standards, this ensures resistance to wind uplift (up to 180 mph) and structural deformation. Bend strength is tested at 180° without cracking, even at -40°C, making them suitable for Arctic or alpine environments.

2. Weight Calculation

- Formula: Weight (kg/m²) = Thickness (mm) × 7.85 (steel density)

- Example: A 0.5 mm sheet weighs 3.925 kg/m², 50% lighter than roofing plastic sheets while offering 3x higher load capacity.

3. Corrosion Resistance Mechanism

The zinc-aluminum coating acts as a sacrificial anode, where zinc oxidizes preferentially to protect the steel core. In coastal zones (chloride-rich environments), the aluminum-rich inner layer forms a stable oxide barrier, preventing rust diffusion. This dual-layer defense ensures a 50+ year lifespan, even under prolonged UV exposure.

4. Why Stainless Steel Can Rust?

- Electrochemical Corrosion: Iron dust or salt deposits create micro-galvanic cells with moisture, accelerating localized pitting.

- Organic Acid Exposure: Pollutants or organic residues (e.g., algae) generate corrosive acids that degrade protective layers over time.

- Mechanical Damage: Scratches during installation expose the substrate, compromising the oxide film’s integrity.

- High-Temperature Degradation: Prolonged exposure to >120°C destabilizes chromium oxide films in stainless steel, leading to scaling.

Key Features

- Weatherproof Design: Withstands -40°C to +150°C, UV radiation (ASTM G154), and salt spray (ASTM B117).

- Cost Efficiency: Factory-direct pricing cuts middleman costs by 40% vs. traditional roof cap sheet suppliers.

- Eco-Friendly: 100% recyclable with GalvaTec™ coating, reducing carbon footprint by 30%.

- Easy Installation: Pre-punched holes and interlocking edges reduce labor time by 50%.

Applications

- Residential: Farmhouses, garages, sheds.

- Agricultural: Barns, poultry sheds, grain storage.

- Commercial: Warehouses, workshops, solar carports.

Why Choose Our Stainless Steel Roofing Sheets?

- Advanced Anti-Corrosion Tech: Dual-layer zinc-aluminum coating provides 3x longer rust resistance than standard galvanized sheets.

- Certified Durability: ASTM and ISO certifications ensure compliance with global construction standards.

- Sustainable Manufacturing: 80% recycled materials and energy-efficient production processes.

- 50-Year Warranty: Limited lifetime coverage against perforation and color fading.

- Aesthetic Flexibility: Choose from 12+ colors and textures to match architectural styles.

Why Our Stainless Steel Stands Out

- Precision Engineering: Laser-cut edges and uniform coating thickness ensure leak-proof performance, even in monsoon climates.

- Global Compliance: Meets EU tariff regulations (HS codes 72101280, 72109040), ensuring seamless international shipments.

- Proven Track Record: Trusted by 10,000+ installations worldwide, including rural infrastructure and agricultural projects.