StockSteel

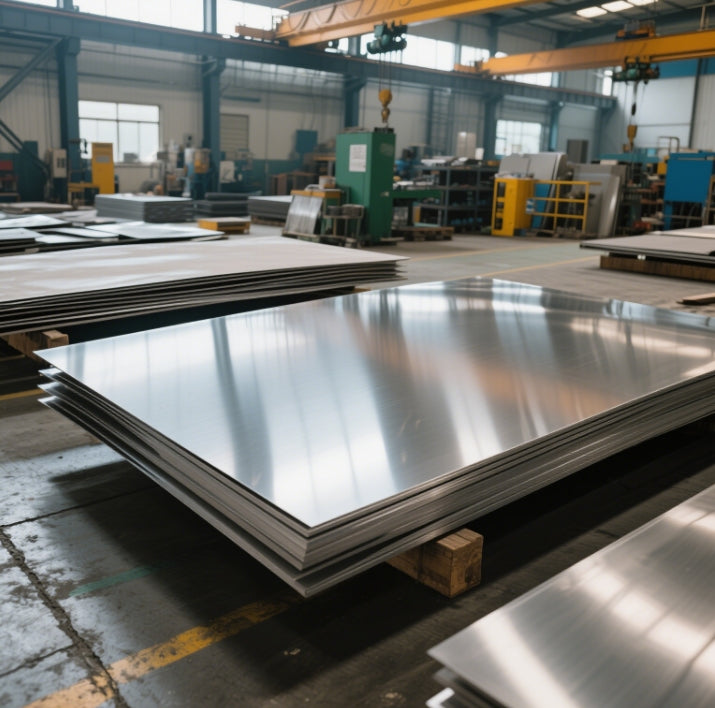

Machined Stainless Steel Metal Plate | 06Cr19Ni10 & Precision Cut

Machined Stainless Steel Metal Plate | 06Cr19Ni10 & Precision Cut

Regular price

$1,550.00 SGD

Regular price

Sale price

$1,550.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Machined Stainless Steel Metal Plate | 06Cr19Ni10 & Precision Cut

Product Specifications

| Parameter | Details |

|---|---|

| Material | 06Cr19Ni10 (UNS S30400, EN 1.4301, JIS SUS304) |

| Thickness | 0.3–30 mm (Cold Rolled), 3–85 mm (Hot Rolled) |

| Width | 36”, 48”, 60” (914–1,524 mm); Custom widths up to 2,200 mm |

| Length | 96”, 120”, 144” (2,438–3,658 mm); Custom lengths up to 12,000 mm |

| Hardness | Rockwell B: ≤92 HRB; Brinell: ≤201 HBW; Tensile Strength: 515–1035 MPa |

| Surface Finish | 2B (Smooth Matte), BA (Bright Annealed), HL (Hairline), No.4 (Brushed), Precision Mirror |

| Machining Process | CNC Cutting, Laser Engraving, Perforation, Edge Polishing, Cold Forming |

Key Properties

-

Tensile & Yield Strength

- 06Cr19Ni10 (304-grade stainless steel) offers a tensile strength range of 515–1035 MPa (74,694–150,000 psi) and yield strength ≥205 MPa (29,740 psi). Its austenitic structure ensures exceptional ductility (≥40% elongation), making it ideal for precision machining and deep drawing. This grade excels in applications requiring structural integrity, such as stainless steel door plates for high-traffic commercial entrances.

-

Bend Strength & Formability

- The alloy’s low carbon content (≤0.08%) minimizes carbide precipitation during welding or bending, allowing complex shapes without cracking. Cold-rolled variants achieve higher strength (up to 550 MPa) for load-bearing components like stainless steel mending plates in construction.

-

Corrosion Resistance

- Chromium (18–20%) and nickel (8–11%) form a self-repairing chromium oxide layer, resisting oxidation, pitting, and crevice corrosion. The 2B finish provides a non-porous surface, ideal for hygienic environments like food processing or medical equipment.

Identification & Marking

- International Standards:

- ASTM: S30400

- EN: 1.4301

- JIS: SUS304

- Laser-etched markings include heat batch numbers, grade certifications, and compliance with ISO 9001 and ASTM A240 standards.

Weight Calculation

Use the formula:

Example: A 2 mm thick 06Cr19Ni10 plate (1.2m × 2.4m) weighs:

Why Stainless Steel Rusts?

Despite its corrosion-resistant reputation, stainless steel can degrade under specific conditions:

- Chloride Exposure: Chlorine ions (in seawater, de-icing salts) penetrate the oxide layer, causing pitting corrosion.

- Mechanical Damage: Scratches or abrasions expose the iron matrix to oxygen, initiating localized rust.

- Low Oxygen Environments: Stagnant water or crevices prevent oxide layer regeneration, leading to crevice corrosion.

- High-Temperature Oxidation: Prolonged exposure above 870°C degrades the protective film, accelerating scaling.

Applications

- Stainless Steel Mending Plate: Used in structural repairs for bridges and machinery, leveraging 06Cr19Ni10’s high tensile strength (≥515 MPa) and weldability.

- Stainless Steel Door Plates: Ideal for commercial entrances with anti-fingerprint finishes (e.g., black stainless steel license plate frame aesthetics) and durability against daily wear.

- Black Stainless Steel License Plate Frame: Powder-coated variants combine corrosion resistance with UV-stable finishes for automotive use.

Why Choose Our Stainless Steel Plates?

- Premium Quality: ISO 9001-certified production with raw materials sourced from TISCO and Baosteel. Third-party SGS inspections ensure compliance with ASTM, EN, and JIS standards.

- Customization: Precision CNC cutting, laser engraving, and edge polishing tailored for stainless steel door plates or mending plates.

- Global Logistics: 10,000+ ton inventory with air/sea shipping options (MOQ: 1 ton).

- Sustainability: 90% recycled content and fully recyclable, aligning with eco-friendly manufacturing practices.

- Technical Support: 24/7 engineering assistance for material selection, fabrication, and corrosion prevention strategies.