StockSteel

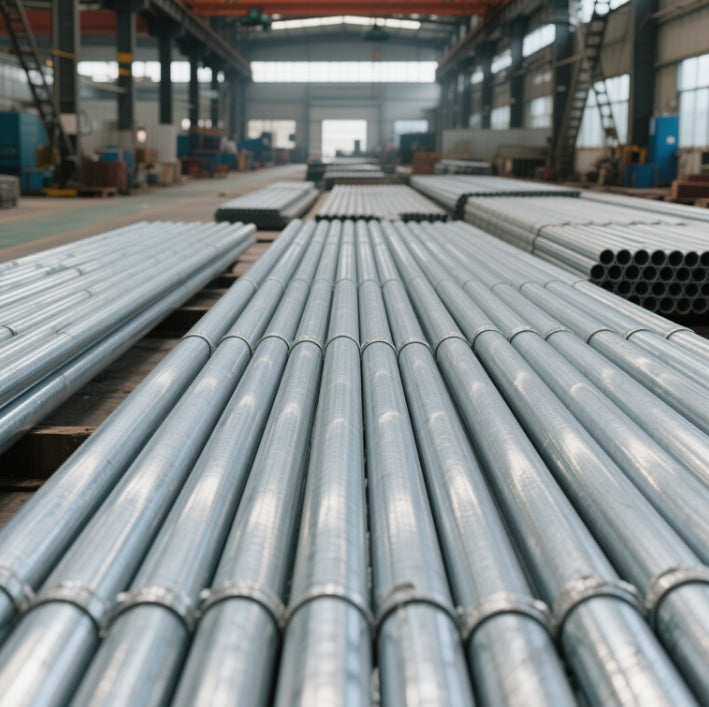

Marine-Grade galvanized pipe fittings | Saltwater Corrosion Resistance

Marine-Grade galvanized pipe fittings | Saltwater Corrosion Resistance

Couldn't load pickup availability

Marine-Grade Galvanized Pipe Fittings | Saltwater Corrosion Resistance

Product Specifications

| Attribute | Technical Details |

|---|---|

| Material Grade | ASTM A123 Hot-Dip Galvanized Carbon Steel / SUS 316 Stainless Steel (Marine Grade) |

| Zinc Coating Thickness | 85–120 μm (3,500–4,200 g/m²) |

| Standards | ISO 1461, ASTM A153, EN 10240, NORSOK M-650 |

| Diameter Range |

1 inch galvanized pipe 20 ft to 8 galvanized pipe (Custom lengths up to 12m) |

| Wall Thickness | SCH 10–SCH 160 (1.2–15 mm) |

| Hardness | 180–220 HV (Vickers) |

| Pressure Rating | 10–60 MPa (PSL1 to PSL2 per API 5L) |

| Temperature Tolerance | -40°C to 400°C (Short-Term Exposure) |

| Thread Compatibility | NPT, BSPT, BSPP (Meets ANSI/ASME B1.20.1) |

| Saltwater Test Compliance | ASTM B117 (5,000+ Hours Salt Spray Resistance) |

Key Performance Features

1. Tensile & Bend Strength

Marine-grade galvanized fittings achieve minimum tensile strength of 415 MPa (ASTM A53 Grade B), ensuring structural integrity in high-pressure marine environments like offshore platforms and ship hulls. The bend strength (245–450 MPa) is validated through three-point bending tests, making them ideal for dynamic applications such as wave-impact zones and ballast systems.

2. Corrosion Resistance

The hot-dip galvanizing process creates a metallurgical bond between zinc and steel, offering 4x longer lifespan than electroplated alternatives. For extreme salinity, SUS 316 stainless steel variants incorporate 2.5% molybdenum to resist pitting corrosion in chloride-rich seawater.

3. Weight Calculation

Use this formula to estimate pipe weight:

Weight (kg/m) = (OD – WT) × WT × 0.02466

Example: 8 galvanized pipe (219 mm OD, 6 mm WT):

(219 – 6) × 6 × 0.02466 = 31.6 kg/m.

Critical Applications

- Ship Plumbing: Complies with DNV-GL & ABS standards for potable water and fuel lines.

- Coastal Infrastructure: Resists salt spray in piers, docks, and desalination plants.

- Offshore Oil Rigs: Withstands hydrogen sulfide corrosion in subsea pipelines.

Why Stainless Steel Outperforms Traditional Options

1. Galvanized vs. Black Pipe vs. Stainless Steel

| Factor | Galvanized | Black Pipe | Stainless Steel |

|---|---|---|---|

| Corrosion Resistance | Moderate (Zinc layer erosion over time)

6

|

None (Prone to rust) | Exceptional (Passive oxide layer)

19

|

| Lifespan | 15–25 years | 5–10 years | 50+ years |

| Maintenance | Annual inspections | Frequent replacements | Minimal |

| Cost Efficiency | Low upfront cost | Lowest initial cost | Higher initial, lower lifecycle cost |

2. Causes of Stainless Steel Corrosion

While rare, corrosion may occur due to:

- Chloride Stress Corrosion Cracking (CSCC): Aggressive in seawater >60°C.

- Galvanic Coupling: Avoid pairing with black pipe or copper alloys without dielectric insulation.

- Mechanical Damage: Scratches exposing base metal to saltwater.

Frequently Asked Questions

Q: How does galvanized pipe compare to stainless steel in saltwater?

A: Galvanized pipe provides cost-effective protection for moderate salinity (e.g., freshwater mix), while stainless steel is mandatory for pure seawater or chemical exposure.

Q: Can I thread 1 inch galvanized pipe 20 ft onsite?

A: Yes! Use ratchet threaders with cutting oil and follow ASME B1.20.1 specs for NPT threads.

Q: What’s the maximum salinity tolerance?

A: Galvanized fittings withstand up to 35,000 ppm salinity (typical seawater). For hypersaline environments (>50,000 ppm), upgrade to SUS 316L.

Why Choose Our Stainless Steel Solutions?

- Superior Material Science: 16–18% chromium + 10–12% nickel alloy matrix prevents biofilm formation, critical for marine drinking water systems.

- Certified Performance: Validated per NORSOK M-650

and ISO 15156 for sour service environments. - Eco-Conscious: 100% recyclable with 60% recycled content, aligning with LEED v4.1 standards.

- Custom Fabrication: Laser-cut threads and orbital welding for precision-fit installations.