StockSteel

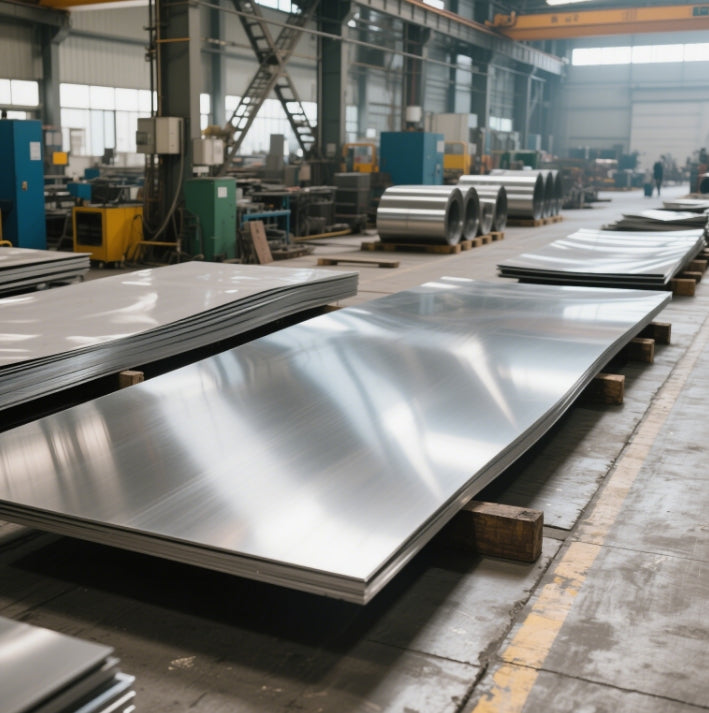

Modular plate stainless steel | Interlocking 2-Section Rail Components

Modular plate stainless steel | Interlocking 2-Section Rail Components

Couldn't load pickup availability

Modular Plate Stainless Steel | Interlocking 2-Section Rail Components

Product Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel (Grades 304, 316L, 2205 duplex) with chromium (16–26%) and nickel (8–22%) |

| Thickness | brushed stainless steel plate: 1mm to 50mm (customizable) |

| Dimensions | Standard: 1000x2000mm, 1219x2438mm; Custom sizes available |

| Surface Finish | black ion-plated stainless steel, No.4 (brushed), HL (hairline), BA (mirror), or custom coatings |

| Hardness | 123–250 HB (Brinell), 70–95 HRB (Rockwell), 129–300 HV (Vickers) |

| Certifications | ASTM A240, EN 10088, ISO 9445 compliant |

| Applications | Rail systems, heavy machinery bases, modular construction, marine infrastructure |

Mechanical & Physical Properties

Tensile Strength

Stainless steel grades like 304 and 2205 duplex exhibit exceptional tensile strength, ranging from 505 MPa (Grade 304) to 800 MPa (Grade 2205). This ensures resistance to deformation under extreme loads, making them ideal for interlocking rail components in high-stress environments. Advanced heat treatment processes further enhance strength by 15–30%, ensuring structural integrity in dynamic applications.

Bend Strength

The ductility of stainless steel allows bending without fracture. For brushed stainless steel plate with ≤10mm thickness, a minimum bend radius of 1x thickness is recommended. Cold working (e.g., rolling) improves bend strength by 20–50%, suitable for seamless 2-section interlocking designs.

Identification & Marking

Stainless steel grades are labeled per international standards:

- ASTM: 304 (S30400), 316L (S31603), 2205 (S32205)

- EN: 1.4301 (304), 1.4404 (316L), 1.4462 (2205)

Laser etching or embossing ensures traceability and compliance with industrial specifications.

Weight Calculation Formula

Calculate plate weight using:

Example: A black ion-plated stainless steel plate of 10mm thickness (1m x 2m) weighs 160 kg.

Why Stainless Steel Corrodes?

While stainless steel resists rust due to chromium oxide layers (≥10.5% Cr), corrosion may occur under specific conditions:

- Chloride Exposure: Coastal or de-icing environments cause pitting corrosion.

- Mechanical Damage: Scratches or abrasions disrupt the passive layer, exposing iron to oxidation.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel) accelerates rusting.

- High Temperatures: Prolonged exposure above 400°C degrades chromium’s protective properties.

Preventive measures include:

- black ion-plated stainless steel coatings for enhanced corrosion resistance.

- Regular cleaning with pH-neutral solutions and passivation treatments.

Can Stainless Steel Be Plated?

Yes, stainless steel can undergo plating processes like ion plating or electroplating to enhance aesthetics or functionality. For example:

- Black ion-plated stainless steel provides a sleek, scratch-resistant surface for architectural applications.

- Nickel or zinc plating improves electrical conductivity for industrial components.

Plating must follow strict protocols to avoid compromising the base material’s corrosion resistance.

Why Choose Our Stainless Steel?

- Premium Material Sourcing: Partnering with certified mills (TISCO, BAOSTEEL) for high-purity alloys.

- Advanced Surface Treatments: Options include brushed stainless steel plate for aesthetics and black ion-plated finishes for durability.

- Custom Solutions: Tailored dimensions, thickness, and coatings (e.g., can stainless steel be plated? Yes—ask about custom plating services).

- Certified Compliance: Meets ASTM, EN, and ISO standards for global industrial use.

- Fast Turnaround: 7–14-day delivery for bulk orders, including precision cutting and bending.

- Technical Support: Expert guidance on welding (TIG/MIG), corrosion prevention, and load optimization.