StockSteel

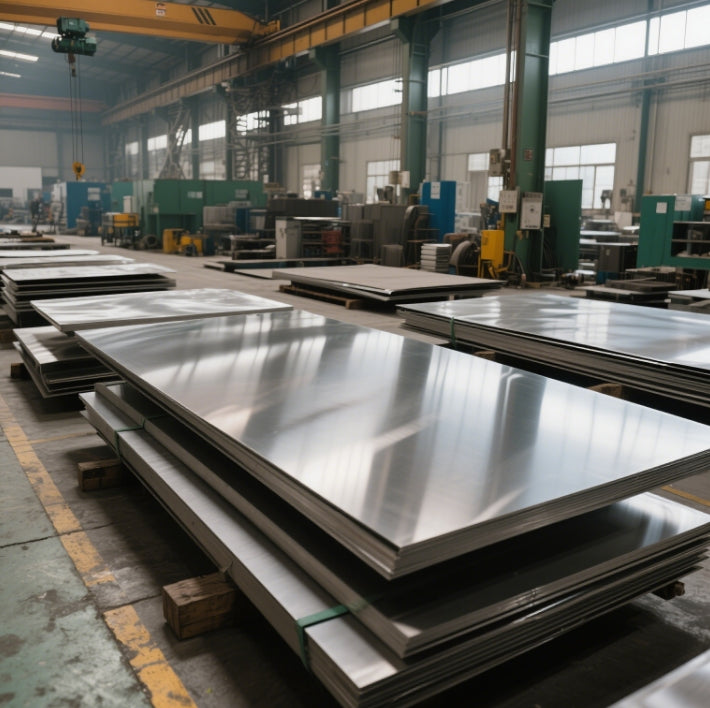

Multi-Purpose plate stainless steel | 2-Section Plates for Rail & Construction

Multi-Purpose plate stainless steel | 2-Section Plates for Rail & Construction

Couldn't load pickup availability

Multi-Purpose Stainless Steel Plates | 2-Section Design for Rail & Construction

Product Overview

Engineered for versatility, our perforated plate stainless steel and license plate frame stainless steel solutions are crafted to excel in heavy-duty rail systems, architectural frameworks, and industrial installations. Combining advanced metallurgical properties with precision manufacturing, these plates deliver unmatched durability, corrosion resistance, and load-bearing capacity.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Grade | ASTM 304, 316L, 430; Duplex 2205 |

| Thickness | 0.6mm – 12mm (Customizable for how to gold plate stainless steel finishes) |

| Standard Size | 4' x 8' (1220mm x 2440mm); Perforated options (3mm–10mm hole diameter) |

| Hardness (HBW) | 180–320 HBW (Varies by grade and heat treatment) |

| Surface Finish | Brushed, mirror, gold-plated (electrolytic coating), or anti-slip perforated patterns |

| Load Capacity | Up to 12,000 lbs/ft² (Dynamic) |

Key Properties & Performance

Tensile Strength

Our stainless steel plates offer exceptional tensile strength, ranging from 450 MPa to 1,000 MPa, depending on the alloy and processing method. For instance:

- ASTM 304: 515–750 MPa (ideal for license plate frame stainless steel due to balanced strength and formability).

- Duplex 2205: 620–1,000 MPa (superior for coastal rail infrastructure with high chloride resistance).

This ensures structural integrity under extreme loads, making them suitable for railway tracks, bridge supports, and seismic-resistant buildings.

Bending Strength

The elastic modulus of 190–210 GPa enables these plates to withstand repeated bending stress without deformation. For perforated plate stainless steel, the bending strength is calculated using:

where = bending strength, = applied moment, = distance from neutral axis, and = moment of inertia. Reinforced edges and perforation patterns further enhance rigidity, reducing deflection in applications like ventilation grilles or decorative facades.

Weight Calculation

Calculate plate weight using:

Example: A 0.6mm stainless steel plate (1.22m x 2.44m) weighs approximately 14.2 kg—ideal for lightweight architectural cladding.

Why Stainless Steel Can Rust?

While stainless steel is corrosion-resistant, rust may occur under specific conditions:

- Chloride Exposure: Coastal environments or de-icing salts can cause pitting corrosion in grades like 430.

- Mechanical Damage: Scratches or improper cleaning disrupt the chromium oxide layer, accelerating oxidation.

- Intergranular Corrosion: Low-quality welding or prolonged exposure to 450–850°C depletes chromium at grain boundaries.

Our plates undergo electropolishing and passivation to restore the protective layer, ensuring longevity even in harsh conditions.

Identification & Marking

Each plate is laser-etched with:

- ASTM Grade (e.g., 316L for marine applications).

- Batch Code for traceability to raw material sources.

- Perforation Pattern ID (e.g., Hex-5M for perforated plate stainless steel).

Compliance with NB/T 20007.5-2021 and GB/T 3280 ensures adherence to nuclear and construction standards.

Customization & Pricing

- Gold-Plating: Learn how to gold plate stainless steel with our electrolytic coating service for decorative or EMI-shielding applications.

- Perforated Designs: Choose from diamond, round, or hexagonal patterns for aesthetics or functional airflow.

- Bulk Orders: Competitive pricing for license plate frame stainless steel starts at 50 per unit (based on thickness and finish).

Why Choose Our Stainless Steel Plates?

- Unmatched Durability: Duplex 2205 and 316L grades offer 100+ years of service life in coastal or high-pollution zones.

- Precision Engineering: CNC laser cutting and perforation ensure ±0.5mm tolerance for seamless integration into rail or construction projects.

- Certified Quality: Compliant with ISO 3651-2 intergranular corrosion tests and EN 10307 ultrasonic inspections.

- Sustainability: 60% recycled content and 100% recyclability align with green building standards.

- Cost Efficiency: Lower lifecycle costs due to zero maintenance and resistance to UV degradation.