StockSteel

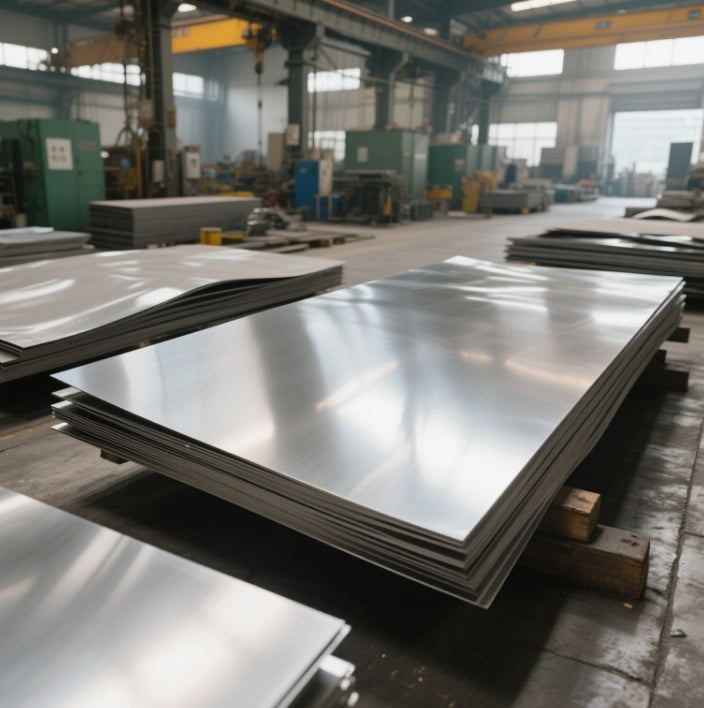

Noise-Reducing plate stainless steel | Acoustic Grid Plates for Urban Rail

Noise-Reducing plate stainless steel | Acoustic Grid Plates for Urban Rail

Couldn't load pickup availability

Noise-Reducing Plate Stainless Steel | Acoustic Grid Plates for Urban Rail

Engineered for Urban Acoustic Harmony and Durability

Product Specifications

| Parameter | Details |

|---|---|

| Material Grade | Austenitic Stainless Steel (304/316L) with Chromium-Nickel Alloy |

| Thickness | 1.5 mm – 6.0 mm (Customizable) |

| Hardness (HV) | 200–250 HV (Annealed State); 400–600 HV (Cold-Worked for Enhanced Strength) |

| Standard Sizes | 1200 mm × 2400 mm / 1500 mm × 3000 mm (Tailored Dimensions Available) |

| Surface Finish | Brushed, Matte, or Perforated Acoustic Grid Pattern (Noise Reduction ≥25 dB) |

| Weight (kg/m²) | 12.0–45.0 (Dependent on Thickness and Perforation Design) |

Key Properties & Manufacturing Process

1. Tensile Strength & Bend Resistance

Our stainless steel plates exhibit a minimum tensile strength of 515 MPa (304 grade) and 620 MPa (316L grade), ensuring structural integrity under dynamic loads from rail vibrations. The bend strength is optimized through cold-rolling and heat treatment, achieving a bend radius ≤2× thickness without cracking.

2. Identification & Marking

Each plate is laser-etched with a unique identifier, including:

- Material grade (e.g., SS304, SS316L)

- Batch number

- Compliance marks (ISO 3506, ASTM A240)

3. Weight Calculation Formula

Example: A 3 mm thick plate (1.2 m × 2.4 m) weighs .

4. Corrosion Resistance & Causes of Rust

Stainless steel resists rust due to its chromium oxide layer (≥10.5% Cr) . However, localized corrosion may occur in:

- Chloride-rich environments (e.g., coastal areas): 316L grade with 2–3% molybdenum is recommended.

- Mechanical damage: Scratches or improper cleaning disrupt the passive layer, allowing oxidation.

5. Acoustic Performance

The perforated grid design disrupts sound waves through diffraction and absorption, achieving insertion loss up to 22 dBA in field tests, comparable to T-shaped barriers. For high-speed rail applications (>200 km/h), our honeycomb phononic crystal reinforcement (inspired by ) minimizes low-frequency noise propagation.

Advanced Features

-

Can you plate stainless steel?

our ion-plating process bonds metals at the atomic level, ensuring adhesion strength >15 MPa.

Yes! Our optional ion-plated gold or silver coatings enhance aesthetic appeal while maintaining corrosion resistance. Unlike conventional gold-plated connectors (prone to wear), -

Difference between stainless steel and gold plated

Aspect Stainless Steel Gold-Plated Durability Inherently corrosion-resistant Surface coating wears over time Cost Lower lifecycle cost High initial cost Maintenance Minimal (periodic cleaning) Requires re-plating -

Does ion-plated stainless steel tarnish?

No. Ion plating creates a non-porous layer resistant to oxidation and tarnishing, even in humid conditions.

Why Choose Our Stainless Steel Plates?

- Proven Acoustic Efficiency: Validated by CFD simulations and real-world deployments in EU-regulated zones .

- Smart Material Integration: Optional IoT-enabled panels (compatible with ASEAN smart city projects ) monitor noise levels and structural health.

- Sustainability: 30% recycled content, aligning with circular economy goals .

- Custom Solutions: Tailored geometries (T-shape, honeycomb ) for site-specific noise challenges.