StockSteel

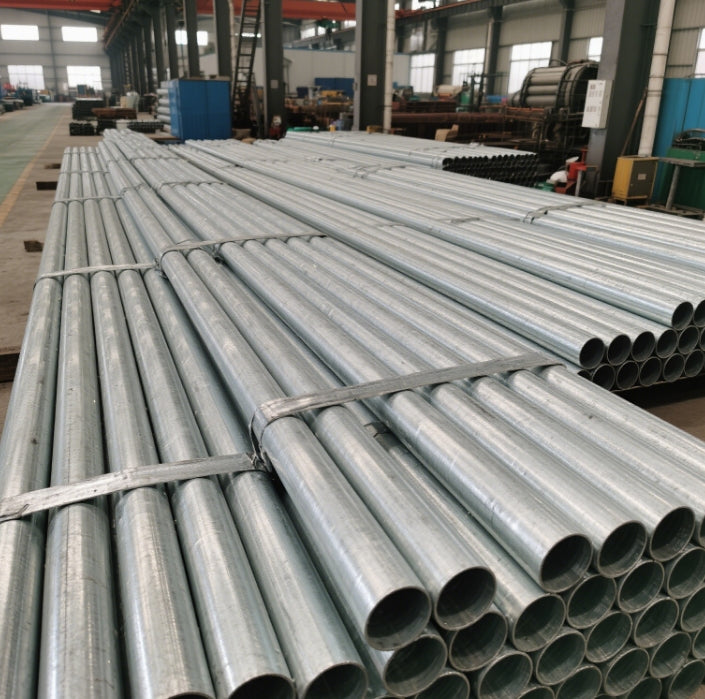

Pre-Galvanized galvanized pipe fittings | Cost-Effective Bulk Orders

Pre-Galvanized galvanized pipe fittings | Cost-Effective Bulk Orders

Couldn't load pickup availability

Pre-Galvanized Galvanized Pipe Fittings: Cost-Effective Bulk Orders

Product Specifications

| Attribute | Details |

|---|---|

| Material | Carbon Steel (Q195, Q235, Q345) / Stainless Steel (304, 316) |

| Surface Treatment | Hot-Dip Galvanized (Zinc Coating: 30–600 g/m²) / Pre-Galvanized Electroplating |

| Standards | ASTM A53, BS 1387, EN 10255, ISO 1461 |

| Diameter Range | 19–273 mm (Round) / Custom Sizes Available |

| Wall Thickness | 0.8–8 mm |

| Hardness | 150–200 HV (Vickers Hardness) |

| Pressure Rating | 1.0–25 MPa (Varies by Wall Thickness) |

| Temperature Resistance | -30°C to 300°C (Short-Term Exposure) |

| Connection Type | Threaded, Welded, Grooved, Flanged |

| Delivery Time | 15–30 Days (Bulk Orders) |

Key Features & Benefits

1. Tensile Strength & Bendability

Pre-galvanized pipe fittings exhibit a minimum tensile strength of 330 MPa (ASTM A53 Grade B), ensuring structural integrity under high-pressure conditions. The bend strength ranges from 245–450 MPa, depending on wall thickness and zinc coating quality, making them suitable for applications requiring flexibility, such as HVAC systems and scaffolding.

2. Corrosion Resistance

The hot-dip galvanizing process creates a metallurgical bond between zinc and steel, offering superior protection against rust and environmental degradation. This makes the fittings ideal for outdoor installations, marine environments, and chemical industries.

3. Weight Calculation

The weight of galvanized pipes can be calculated using the formula:

Weight (kg/m) = (OD – WT) × WT × 0.02466

Example: For a 50 mm OD pipe with 3 mm wall thickness:

(50 – 3) × 3 × 0.02466 = 3.48 kg/m.

Common Applications

- Drinking Water Systems: Compliant with NSF/ANSI 61 standards for safe potable water transport.

- Fire Protection: Meets ASTM A795 specifications for sprinkler systems.

- Industrial Plumbing: Resists scaling and mineral buildup, reducing maintenance costs.

Why Stainless Steel? Addressing Rust & Safety Concerns

Stainless steel alternatives are recommended for applications requiring long-term hygiene or high chemical resistance. Here’s why stainless steel outperforms traditional galvanized pipes:

1. Causes of Rust in Galvanized Pipes

- Zinc Depletion: Over time, the zinc layer erodes, exposing the base steel to moisture.

- Acidic Water: pH levels below 6.5 accelerate corrosion, leading to pinhole leaks.

- Mechanical Damage: Scratches during installation compromise the protective coating.

2. Safety for Drinking Water

While galvanized pipes are generally safe, aged systems may leach zinc or lead (from older fittings). For modern installations, stainless steel ensures zero contamination and complies with global potable water regulations.

Frequently Asked Questions

1. How much does it cost to replace galvanized pipes?

Replacement costs range from 15,000 for residential systems, depending on pipe length and accessibility. Stainless steel upgrades add 20–30% to the initial cost but reduce long-term maintenance expenses.

2. How to thread galvanized pipe

- Use a manual ratchet threader or electric threading machine.

- Apply cutting oil to reduce friction.

- Follow ANSI/ASME B1.20.1 standards for thread pitch and depth.

3. Is galvanized pipe safe for drinking water?

New galvanized pipes meet NSF/ANSI 61 standards. However, stainless steel is preferred for eliminating risks of zinc leaching and biofilm formation.

Why Choose Our Stainless Steel Solutions?

- Superior Corrosion Resistance: Chromium-rich alloys (16–20% Cr) form a self-healing oxide layer, preventing rust even in chloride-rich environments.

- Lifespan: Exceeds 50 years with minimal maintenance, outperforming galvanized steel by 2–3x.

- Eco-Friendly: 100% recyclable and compliant with LEED certification requirements.

- Certifications: Tested to ASTM A312, EN 10217-7, and ISO 9001 standards.