StockSteel

Precision-Crafted plate stainless steel | Elevator & Staircase Safety Solutions

Precision-Crafted plate stainless steel | Elevator & Staircase Safety Solutions

Couldn't load pickup availability

Precision-Crafted Stainless Steel Plate | Elevator & Staircase Safety Solutions

Product Overview

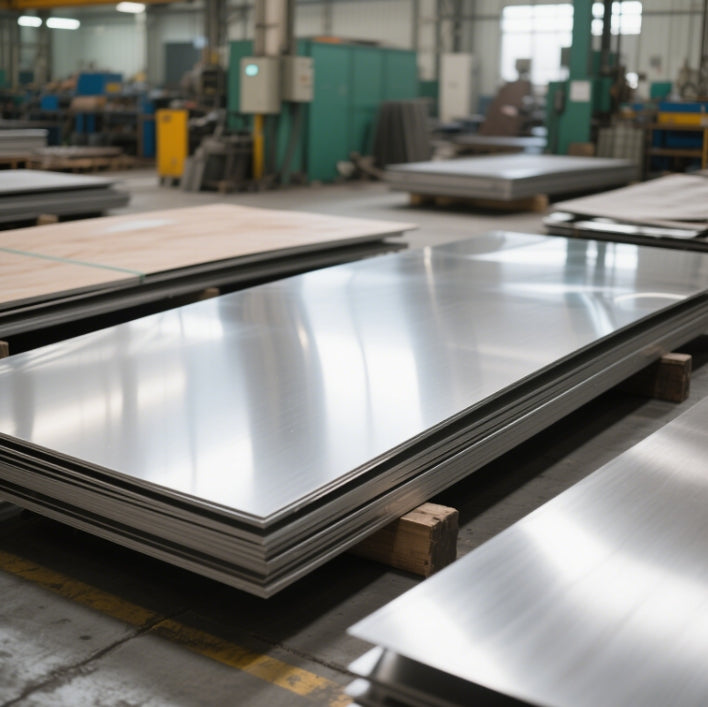

Our precision-crafted stainless steel plates are engineered to meet the highest safety and durability standards for elevators, staircases, and architectural structures. Designed with stainless steel square plate configurations and stainless steel wall plate applications, these plates combine industrial-grade strength with aesthetic versatility. Available in 1/4 stainless steel plate thickness for heavy-duty use, they comply with ISO 9001, ASTM A240, and EN 10088-2 certifications, ensuring reliability in high-traffic environments.

Specifications & Properties

| Property | Details |

|---|---|

| Material | 304, 316L, 430 stainless steel (high chromium-nickel alloys) |

| Thickness | 1.6mm–25mm (standard 1/4 stainless steel plate at 6.35mm) |

| Width | 500mm–2000mm (adjustable for stainless steel square plate or wall plate designs) |

| Length | 1m–6m (custom lengths available) |

| Surface Finish | Brushed, Embossed (anti-slip), PVD Coated (scratch-resistant), Mirror Polished |

| Hardness | 304: HRB 70–88; 316L: HRB 75–95; 430: HRB 80–95 |

| Certifications | ISO 9001, ASTM A240, EN 10088-2, LEED |

| Processing | Laser Cutting, CNC Stamping, Roll Forming, TIG Welding |

Key Features

1. Tensile & Bend Strength

- Tensile Strength: Ranges from 515 MPa (304 grade) to 620 MPa (316L), ensuring structural integrity for load-bearing applications like elevator floors or staircase treads. Cold-rolled variants achieve higher yield strength (up to 310 MPa), minimizing deformation under dynamic loads.

- Bend Strength: Engineered to withstand repeated bending without cracking, even at sub-zero temperatures. This flexibility is critical for curved stainless steel wall plate installations or architectural cladding.

2. Identification & Weight Calculation

- Identification: Grades are laser-etched per ASTM/EN standards (e.g., "316L" for marine-grade steel) with traceability codes for quality audits.

- Weight Formula:Example: A 1/4 stainless steel plate (6.35mm) × 1m × 2m weighs 100.7 kg.

3. Corrosion Resistance & Rust Prevention

Stainless steel’s chromium content (≥10.5%) forms a self-repairing oxide layer to block oxidation. However, localized rust may occur due to:

- Chloride Exposure: Coastal environments or de-icing salts accelerate pitting. Our 316L grade includes 2-3% molybdenum for superior chloride resistance.

- Mechanical Damage: Scratches from abrasive tools compromise the oxide layer. Electro-polishing restores surface integrity and corrosion resistance.

- Galvanic Corrosion: Direct contact with carbon steel triggers electrochemical reactions. Insulating gaskets are recommended for mixed-material installations.

Applications

- Elevator Safety: Anti-slip stainless steel square plate flooring with embossed textures for secure footing.

- Staircase Construction: Durable stainless steel wall plate cladding for high-traffic public spaces.

- Architectural Design: Custom 1/4 stainless steel plate panels for façades, balustrades, and signage.

Why Choose Our Stainless Steel Plates?

- Precision Engineering: Advanced CNC and laser-cutting technologies ensure ±0.1mm dimensional accuracy.

- Certified Safety: Compliant with ASTM E84 fire ratings and ISO 14001 environmental standards.

- Custom Solutions: Tailored thicknesses, finishes (e.g., PVD coatings), and embossing patterns for unique projects.

- Global Logistics: Bulk orders shipped within 15–30 days; samples available in 5–7 days.

- Eco-Conscious: 70% recycled content and low-energy manufacturing processes reduce carbon footprint.