StockSteel

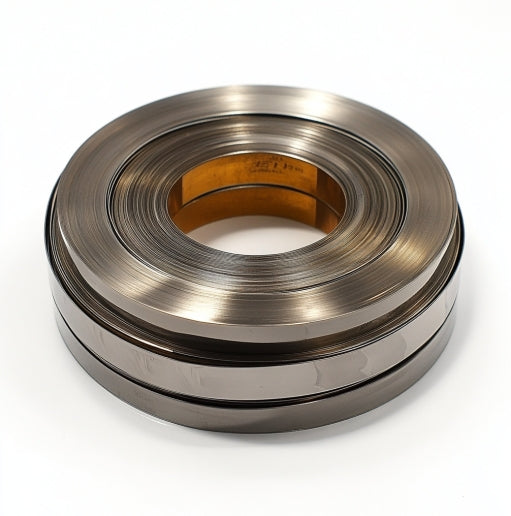

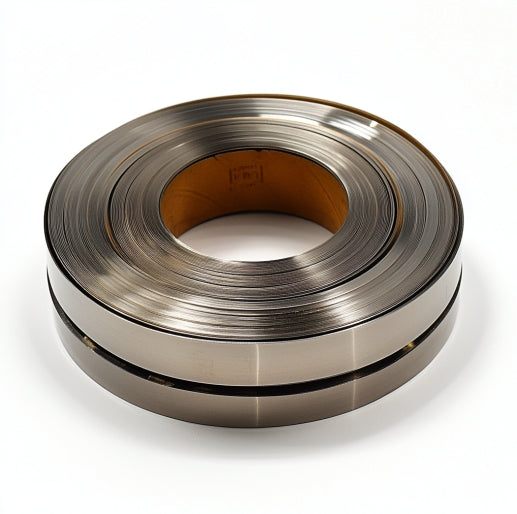

Precision-Engineered Stainless Steel Metal Strips | AISI 304L/316

Precision-Engineered Stainless Steel Metal Strips | AISI 304L/316

Couldn't load pickup availability

Precision-Engineered Stainless Steel Metal Strips | AISI 304L/316

Technical Specifications

| Property | Detail |

|---|---|

| Material | AISI 304L/316 stainless steel (low carbon, high corrosion resistance) |

| Thickness | 0.1 mm – 5.0 mm (±0.01 mm tolerance) |

| Width | 10 mm – 600 mm (customizable) |

| Hardness (Rockwell B) | 85–95 HRB (304L) / 90–100 HRB (316) |

| Surface Finish | Mirror polish, brushed, sandblasted, or 2B/BA finish |

| Tensile Strength | 485–620 MPa (304L) / 520–690 MPa (316) |

| Yield Strength | 170–310 MPa (304L) / 205–310 MPa (316) |

| Elongation | 35–60% (304L) / 30–50% (316) |

| Density | 7.93 g/cm³ (304L) / 7.98 g/cm³ (316) |

| Certifications | ASTM A240, EN 10088-2, ISO 9001 |

Performance Attributes

Tensile & Bending Strength

Our stainless steel metal strips excel in demanding environments due to their optimized tensile and bending strength. The AISI 316 variant achieves **≥520 MPa tensile strength**, ideal for high-stress applications like aerospace fasteners or marine hardware. For AISI 304L, the lower carbon content (<0.03%) enhances weldability while maintaining **≥485 MPa tensile strength**, suitable for food processing equipment and architectural trim. Cold-rolling processes ensure uniform grain structure, reducing brittleness and improving formability.

Identification & Traceability

Each stainless steel strip roll is laser-marked with a unique identifier (e.g., “316L-0.5MM-EN10088”), including material grade, thickness, and certification codes. This aligns with industrial standards for quality control and traceability.

Weight Calculation

The weight of a stainless steel trim strip can be calculated using:

For example, a 1.2 mm × 50 mm × 10 m 304L strip weighs 4.76 kg. Custom lengths and slitting services are available for precision projects.

Why Stainless Steel Can Rust

While stainless steel metal strips resist corrosion, rust may occur under extreme conditions:

- Chloride Exposure: Prolonged contact with seawater or de-icing salts degrades the passive chromium oxide layer.

- Mechanical Damage: Scratches or improper handling expose the base metal to oxygen and moisture.

- Galvanic Corrosion: Contact with carbon steel or copper in humid environments accelerates oxidation.

Our 316 strips mitigate these risks with 2–3% molybdenum, enhancing pitting resistance in marine or chemical settings.

Craftsmanship & Manufacturing

- Cold Rolling: Precision cold-rolling reduces thickness to ±0.01 mm tolerances, ensuring uniformity for stainless steel trim strips used in automotive or electronics.

- Annealing & Pickling: Bright annealing (BA) under hydrogen gas eliminates surface oxides, while pickling removes scale for a corrosion-ready finish.

- Slitting & Edge Finishing: Razor-sharp slitting achieves burr-free edges, critical for medical devices or precision machinery components.

Applications

- Architectural Trim: Stainless steel trim strips provide sleek, rust-resistant edging for façades and interiors.

- Automotive: Exhaust systems and trim utilize 316 strip rolls for heat and chemical resistance.

- Medical & Food Processing: 304L strips meet hygiene standards for surgical tools and conveyor belts.

Why Choose Our Stainless Steel Strips?

- Superior Material Quality: AISI 304L/316 grades comply with ASTM/EN standards, validated by third-party inspections.

- Precision Manufacturing: ±0.01 mm tolerances and custom finishes meet aerospace and medical industry demands.

- Global Certifications: ISO 9001 and RoHS compliance ensure reliability for export markets.

- Sustainable Production: 100% recyclable materials and energy-efficient cold-rolling processes.

- Technical Support: Dedicated engineering team for custom dimensions, prototyping, and application guidance.