StockSteel

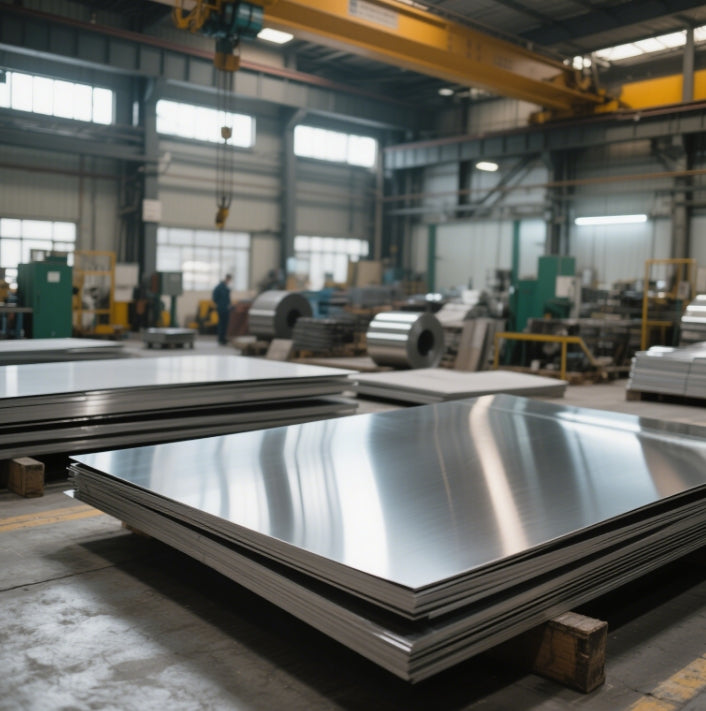

Precision stainless steel plate | CNC-Machined for Technical Components

Precision stainless steel plate | CNC-Machined for Technical Components

Regular price

$1,380.00 SGD

Regular price

Sale price

$1,380.00 SGD

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

Precision Stainless Steel Plate | CNC-Machined for Technical Components

Technical Specifications

| Property | Details |

|---|---|

| Material Grades | 304 (AISI 304), 316L, 303 (Free-Machining Grade), 17-4PH (Precipitation-Hardened) |

| Thickness | 0.5–80 mm (Standard: plat stainless steel 304 [6.35 mm]; Customizable: 0.02–100 mm) |

| Width | 1000–2500 mm (Industrial Standard: 1219 mm, 1500 mm) |

| Length | 2000–8000 mm (Customizable up to 20,000 mm) |

| Surface Finish | 2B, BA, Ion Plated Stainless Steel (IP Coating), Brushed, Mirror (8K) |

| Hardness (HV) | 304: 170–200 HV; 316L: 180–220 HV; 17-4PH: 300–500 HV (Heat-Treated) |

| Processing | CNC Machining, Cold/Hot Rolling, Precision Laser Cutting, Electrolytic Polishing |

Performance & Features

1. Tensile Strength

Our plat stainless steel 304 series combines machinability with robust mechanical properties:

- Grade 304: Delivers 515–700 MPa, ideal for structural components in aerospace and automotive industries .

- Grade 316L: Offers 520–670 MPa with enhanced chloride resistance, perfect for marine environments .

- Grade 17-4PH: Achieves 1,100–1,300 MPa post-heat treatment, suitable for high-stress applications like turbine blades .

Compliance with ASTM A240 and ISO 3506 ensures material consistency, validated by Mill Test Reports (MTRs) .

2. Bending Strength

Engineered for precision in CNC machining:

- Thin plates (≤6 mm) withstand 180° bends without cracking (per GB/T 232-2010), critical for forming stainless steel cover plate edges .

- Thick plates (>10 mm) require controlled radii (≥3× thickness) to prevent stress fractures in load-bearing frameworks .

3. Identification & Marking

Each plate features laser-etched identifiers for traceability:

- Grade designation (e.g., SUS304, 316L).

- Batch number, heat treatment code, and compliance marks (e.g., ASTM, EN) .

Custom ion plated stainless steel surfaces include anti-corrosion QR codes for quality tracking.

4. Weight Calculation

Use the formula for precise engineering designs:

Example: A plat stainless steel 304 (6.35 mm × 1.5 m × 3 m) weighs 226 kg – optimized for CNC-machined brackets or stainless steel cover plate systems .

5. Why Stainless Steel Can Rust?

Even high-grade plat stainless steel 304 may corrode under specific conditions:

- Chloride Exposure: Coastal environments or chemical spills induce pitting in 304-grade steel .

- Mechanical Damage: Scratches from CNC tools disrupt the chromium oxide layer, necessitating ion plated stainless steel coatings for enhanced protection .

- Intergranular Corrosion: Poor welding in 316L reduces molybdenum’s chloride resistance, requiring post-weld annealing .

Regular maintenance with pH-neutral cleaners and avoiding galvanic coupling (e.g., with carbon steel) preserves integrity .

Applications

- Aerospace: Engine mounts, hydraulic components (plat stainless steel 304).

- Electronics: Ion plated stainless steel EMI shielding plates, heat sinks.

- Industrial: Stainless steel cover plate systems for machinery protection.

- Medical: Surgical instrument trays, sterilizable housings (316L grade).

Why Choose Our Precision Stainless Steel Plates?

- Superior Machinability: Optimized plat stainless steel 304 with sulfur additives reduces tool wear by 30% .

- Advanced Coatings: Ion plated stainless steel surfaces achieve ≤0.8 μm roughness (Ra), ideal for high-precision components .

- Certified Quality: Compliant with ISO 9001, RoHS, and ASTM A240, backed by full traceability .

- Custom Solutions: Tailored CNC machining (±0.05 mm tolerance) for complex geometries .

- Sustainability: 100% recyclable material with low-VOC production processes .