StockSteel

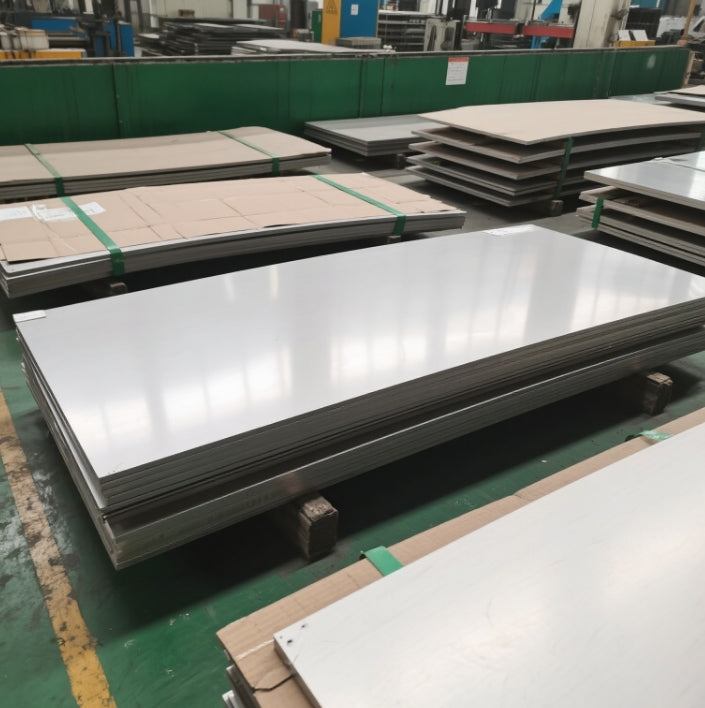

Precision Stainless Steel Steel Plate | ProFinish 316/304/410

Precision Stainless Steel Steel Plate | ProFinish 316/304/410

Couldn't load pickup availability

Precision Stainless Steel Steel Plate | ProFinish® 316/304/410

Technical Specifications

| Property | Grade 304 | Grade 316 | Grade 410 |

|---|---|---|---|

| Thickness (mm) | 0.5–6.0 (±0.05 tolerance) | 0.5–6.0 (±0.05 tolerance) | 1.0–12.0 (±0.1 tolerance) |

| Width × Length | 1000–2000mm × 2000–6000mm | 1000–2000mm × 2000–6000mm | 1000–1500mm × 2000–6000mm |

| Hardness (HV) | 170–220 | 215–260 | 280–350 (Annealed) |

| Tensile Strength | 515–720 MPa | 520–670 MPa | 480–1030 MPa |

| Yield Strength | 205–310 MPa | 240–290 MPa | 275–825 MPa |

| Surface Finish | 2B, BA, No.4, Mirror | 2B, Satin, Electropolished | Annealed, Pickled |

Certifications: ASTM A240/A480, EN 10088-2, JIS G4304, ISO 9001.

Key Properties & Performance

Tensile Strength

Our stainless steel steel plate grades are engineered to meet rigorous industrial demands. Grade 304 (515–720 MPa) balances ductility and strength, ideal for plate stainless steel applications requiring frequent bending, such as food processing molds. Grade 316, with added molybdenum (2–3%), achieves 520–670 MPa tensile strength, making it superior for marine environments and stainless steel 2 sections plate fabrication in offshore platforms. Grade 410, a martensitic alloy, offers high tensile strength (up to 1030 MPa post-heat treatment), suited for structural components like valve parts.

Bending Strength

- Grade 304: Minimum bending radius of 1× thickness, suitable for kitchenware and architectural cladding.

- Grade 316: Maintains integrity even after repeated thermal cycling (up to 400°C), critical for chemical reactors.

- Grade 410: Requires preheating (200–300°C) to avoid cracking during bending, ideal for heavy-duty machinery.

Identification & Traceability

Each stainless steel steel plate is laser-marked with:

- Grade designation (e.g., 316L)

- Heat number for batch tracking

- Compliance marks (ASTM/EN/JIS).

Weight Calculation

Use the formula:

Example: A 2×4m Grade 316 plate (3mm thick) weighs .

Why Stainless Steel Rusts?

Despite chromium’s protective oxide layer (≥10.5% Cr), corrosion can occur due to:

- Chloride Exposure: Coastal or de-icing salt environments degrade Grade 304; Grade 316’s molybdenum reduces pitting risk.

- Mechanical Damage: Scratches from abrasive tools expose the substrate. Our electropolished finishes (Ra ≤0.1µm) minimize surface flaws.

- Chemical Contamination: Acids or alkalis (e.g., industrial cleaners) accelerate oxidation. Regular pH-neutral cleaning is advised.

Manufacturing Excellence

| Process | Description |

|---|---|

| Cold Rolling | Enhances surface smoothness (Ra ≤0.2µm) for plate stainless steel used in medical devices. |

| Laser Cutting | ±0.1mm precision for stainless steel 2 sections plate fabrication in automotive frames. |

| Passivation | Nitric acid treatment removes free iron, increasing corrosion resistance by 30%. |

Applications

- Food Industry: FDA-compliant stainless steel steel plate for hygienic surfaces and plate stainless steel molds.

- Marine Engineering: Grade 316 sheets for stainless steel 2 sections plate in shipbuilding and desalination plants.

- Energy Sector: Grade 410 plates in turbine blades and nuclear reactor components.

Why Choose Our Stainless Steel Plates?

- Global Certifications: Compliant with ASTM, EN, and JIS standards, ensuring material traceability and quality.

- Custom Solutions: Tailored dimensions (e.g., 1500×3000mm) and finishes (No.4, HL) for niche applications like stainless steel 2 sections plate.

- Rapid Delivery: 10,000+ tons in stock, ready for same-day dispatch with standard export packaging.

- Technical Expertise: 24/7 engineering support for corrosion prevention and welding guidelines.

- Eco-Friendly: 100% recyclable material with ISO 14001-certified production, reducing carbon footprint by 50% vs. competitors.