StockSteel

Premium-Grade Stainless Steel Dining Plates | 316L 2B/HL/8K Finish

Premium-Grade Stainless Steel Dining Plates | 316L 2B/HL/8K Finish

Couldn't load pickup availability

Premium-Grade Stainless Steel Dining Plates | 316L 2B/HL/8K Finish

Product Overview

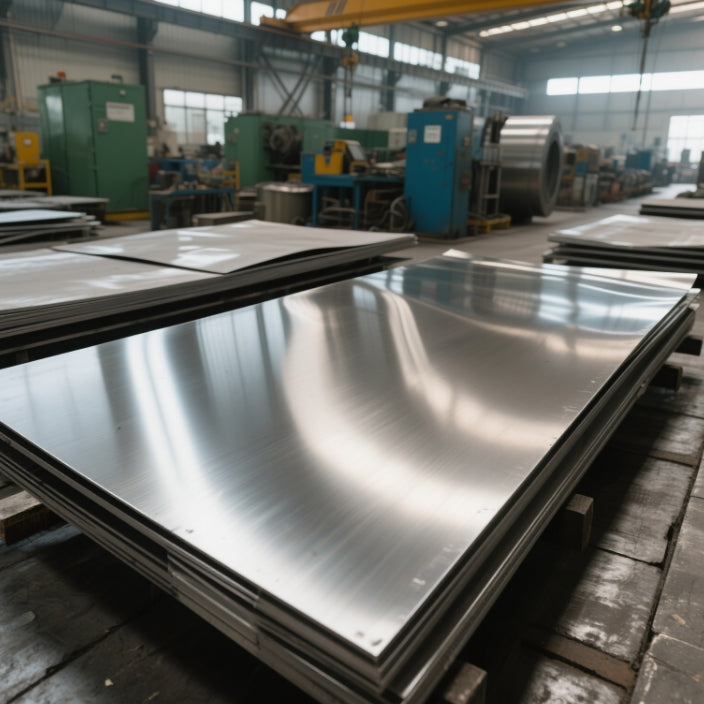

Crafted for elegance and durability, our stainless steel dining plates combine industrial-grade performance with refined aesthetics. Designed for high-end culinary and hospitality applications, these plates are available in 316L stainless steel with 2B, Hairline (HL), and 8K mirror finishes, ensuring corrosion resistance, hygiene, and visual appeal. Ideal for stainless steel charger plates in luxury settings, they meet ASTM/EN standards and are customizable for global commercial and residential use.

Technical Specifications

| Attribute | Details |

|---|---|

| Material Grade | 316L (1.4404), 304L (1.4307), Custom Alloys |

| Thickness | 0.5mm–6.0mm (Cold/Hot Rolled) |

| Width | 200mm–1500mm (Standard), Custom Sizes Available |

| Surface Finish | 2B Matte, HL Brushed, 8K Mirror, Embossed, Custom Patterns |

| Hardness (HV) | 150–220 (Annealed); 300–350 (Cold-Rolled) |

| Tensile Strength | 515–860 MPa (316L Grade) |

| Yield Strength | 205–310 MPa (316L Grade) |

| Processing | Cold Rolling, Precision Stamping, Laser Cutting, Electroplating, Polishing |

Key Properties

1. Tensile & Bend Strength

The stainless steel dining plates achieve tensile strengths of 515–860 MPa (316L grade), ensuring structural integrity under heavy use. This makes them resistant to deformation in high-pressure environments like commercial kitchens or banquet halls. Bend strength is optimized through cold-rolling processes, allowing seamless integration into curved designs for stainless steel charger plates without compromising durability.

2. Weight Calculation

Use our stainless steel plate weight calculator for precise material planning:

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (7.93 g/cm³)

Example: A 2mm × 0.5m × 0.5m plate weighs 3.96 kg. This tool simplifies inventory management and cost estimation for bulk orders.

3. Corrosion Resistance & Rust Prevention

316L stainless steel contains 16–18% chromium and 2–3% molybdenum, forming a self-repairing passive oxide layer that resists rust. However, corrosion may occur due to:

- Mechanical Damage: Scratches from abrasive tools expose the base metal to moisture.

- Chemical Exposure: Chlorides (e.g., saltwater) or acidic foods degrade the oxide layer over time.

- Galvanic Corrosion: Contact with dissimilar metals (e.g., carbon steel) in humid environments.

To mitigate risks, avoid harsh cleaners and store plates separately from reactive materials.

4. Surface Finish Options

- 2B Matte: A smooth, non-reflective finish ideal for industrial kitchens.

- HL Brushed: A linear texture offering scratch resistance for stainless steel charger plates.

- 8K Mirror: A high-gloss polish for luxury dining aesthetics.

Applications

- Hospitality: Stainless steel dining plates for hotels, cruise ships, and fine-dining restaurants.

- Food Processing: Hygienic surfaces for meat, dairy, and beverage industries.

- Residential: Sleek charger plates for modern table settings.

Why Choose Our Stainless Steel?

-

Superior Material Quality

Our 316L stainless steel exceeds ASTM A240 and EN 1.4404 standards, ensuring longevity in extreme environments. -

Customization Flexibility

Tailor dimensions, finishes, and patterns (e.g., embossed logos) for branding or functional needs. -

Eco-Friendly & Recyclable

100% recyclable with no toxic leaching, aligning with global sustainability goals. -

Global Certification

ISO 9001, SGS, and RoHS certifications guarantee safety and performance. -

Competitive Pricing

Bulk discounts and streamlined logistics reduce costs without compromising quality.

Elevate your culinary experience with plates that blend hygiene, durability, and timeless design.