StockSteel

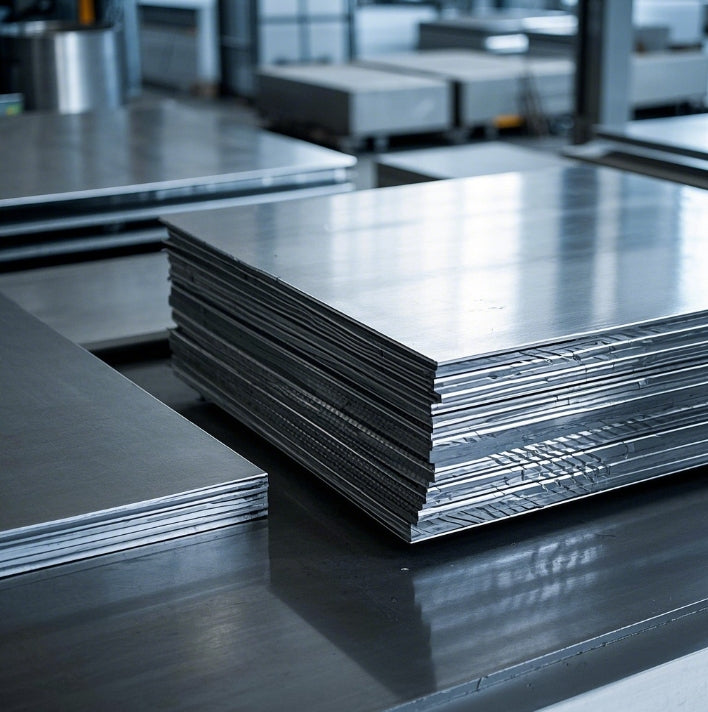

Premium Plate Stainless Steel | SS304/316L Cold Rolled Mastery

Premium Plate Stainless Steel | SS304/316L Cold Rolled Mastery

Couldn't load pickup availability

Premium Plate Stainless Steel | SS304/316L Cold Rolled Mastery

Product Specifications

Material Grades: Stainless steel plate grades AISI 304, 316L

Thickness Range: 1mm–3mm (Customizable)

Standards: ASTM A240, EN 10088-3, JIS G4304

| Property | Value |

|---|---|

| Hardness (Rockwell B) | 70-90 HRB (304), 75-95 HRB (316L) |

| Tensile Strength | 515-930 MPa (304), 520-860 MPa (316L) |

| Yield Strength | 205-310 MPa (304), 220-300 MPa (316L) |

| Surface Finish | 2B, BA, No.4, Cold Rolled (HRAP) |

| Density | 8.0 g/cm³ (304), 8.0 g/cm³ (316L) |

| Thermal Conductivity | 16.2 W/m·K (304), 15.0 W/m·K (316L) |

| Corrosion Resistance | Excellent (304), Superior (316L) |

Mechanical & Functional Properties

Tensile Strength

Our plate stainless steel in grades 304 and 316L delivers exceptional tensile strength, ranging from 515 MPa to 930 MPa, making it ideal for high-stress applications like stainless steel railroad tie plates and structural frameworks. The 316L variant, enriched with 2-3% molybdenum, resists pitting corrosion in chloride-rich environments such as coastal railways or chemical plants.

Bend Strength

Cold-rolled precision ensures superior bend performance. For 304-grade plates, the minimum bend radius is 1x thickness (1mm–3mm), while 316L’s ductility allows tighter bends without cracking. This property is critical for forming stainless steel railroad tie plates that withstand heavy rail loads.

Weight Calculation

Formula:

Weight (kg) = Thickness (mm) × Width (m) × Length (m) × Density (g/cm³)

Example: A 2mm × 1.2m × 2.4m plate stainless steel (304 grade) weighs 2 × 1.2 × 2.4 × 8.0 = 46.08 kg.

Identification Methods

Grades are laser-marked per ASTM A480 standards. 304 plates are labeled with “AISI 304” or “SUS304,” while 316L plates include “Mo” to denote molybdenum content.

Why Stainless Steel Rusts?

Although stainless steel plate grades are corrosion-resistant, rust can occur under specific conditions:

- Chloride Exposure: Prolonged contact with seawater or de-icing salts may cause pitting in 304 steel. 316L’s molybdenum content mitigates this risk.

- Galvanic Corrosion: Contact with carbon steel tools or iron particles triggers electrochemical reactions. Always use stainless-specific tools during installation.

- Welding Defects: Improper TIG/MIG techniques (e.g., inadequate gas shielding) reduce 316L’s intergranular corrosion resistance. Post-weld pickling is recommended.

Applications

- Railway Infrastructure: Stainless steel railroad tie plates (316L) resist saltwater corrosion and heavy axle loads.

- Food Processing: Cold-rolled 304 sheets are polished to a No.4 finish for hygienic plate stainless steel countertops and conveyor systems.

- Marine Hardware: 316L-grade plates are used for boat fittings and dock components due to superior saltwater resistance.

Why Choose Our Stainless Steel Plates?

- Certified Quality: Compliant with ASTM A240 and EN 10088-3 standards, backed by Mill Test Certificates (EN 10204 3.1/3.2).

- Custom Solutions: Tailored dimensions (1mm–3mm), perforated designs, and PVC coatings for stainless steel railroad tie plates or kitchenware.

- Global Stock: Ready-to-ship inventory across North America, Europe, and Asia.

- Technical Support: Expert guidance on welding, cutting, and maintenance to maximize longevity.

- Cost Efficiency: Competitive pricing with factory-direct supply, eliminating intermediaries.