StockSteel

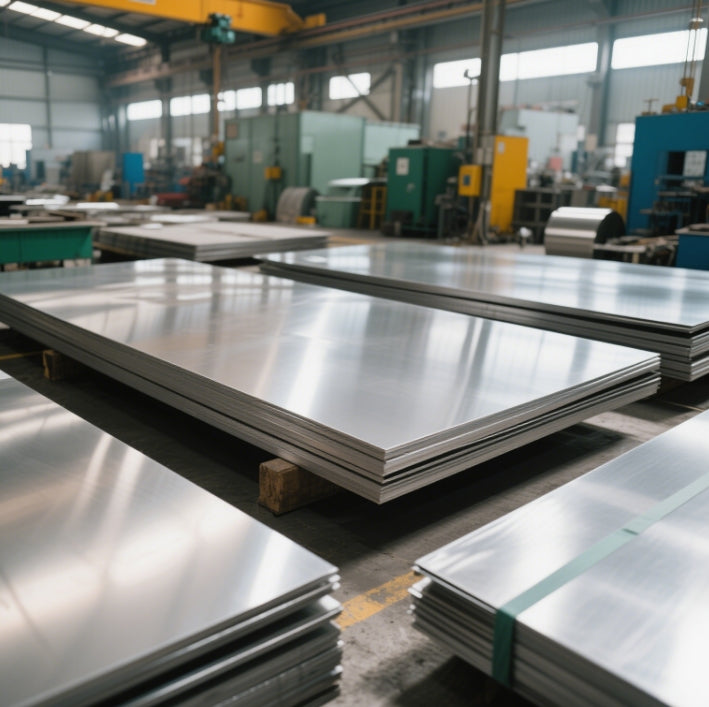

Premium Stainless Steel Metal Plate | 304L & 316L Certified

Premium Stainless Steel Metal Plate | 304L & 316L Certified

Couldn't load pickup availability

Premium Stainless Steel Metal Plate | 304L & 316L Certified

Engineered for Durability, Safety, and Versatility

Product Specifications

| Parameter | 304L Stainless Steel | 316L Stainless Steel |

|---|---|---|

| Material Grade | UNS S30403 (AISI 304L) | UNS S31603 (AISI 316L) |

| Thickness | 0.5 mm – 50 mm (Customizable) | 0.5 mm – 50 mm (Customizable) |

| Hardness (HV) | 200–250 HV (Annealed) / 400 HV (Cold-Worked) | 220–260 HV (Annealed) / 420 HV (Cold-Worked) |

| Standard Sizes | 1000 mm × 2000 mm, 1219 mm × 2438 mm, Custom Sizes | 1000 mm × 2000 mm, 1219 mm × 2438 mm, Custom Sizes |

| Surface Finish | 2B, BA, No.4, HL, Mirror (8K) | 2B, BA, No.4, HL, Mirror (8K) |

| Weight (kg/m²) | 3.96–396 (Based on Thickness) | 3.96–396 (Based on Thickness) |

Key Properties & Manufacturing Process

1. Tensile Strength & Bend Resistance

Our 304L stainless steel plates deliver a minimum tensile strength of 485 MPa and yield strength of 170 MPa, making them ideal for structural applications requiring moderate stress resistance. The 316L grade excels with tensile strength up to 515 MPa and yield strength of 205 MPa, enhanced by molybdenum for superior performance in corrosive environments. Both grades undergo cold-rolling and annealing to achieve a bend radius ≤2× thickness without cracking, ensuring flexibility for complex designs like oversized stainless steel wall plates.

2. Identification & Traceability

Each plate is laser-etched with:

- Material grade (e.g., 304L, 316L)

- Batch number and heat code

- Compliance marks (ASTM A240, ISO 3506, EN 1.4307/1.4404).

This ensures full traceability for critical sectors like food processing and medical equipment, where non-toxic stainless steel kids plates require stringent quality control.

3. Weight Calculation Formula

Example: A 304L plate measuring 3 mm × 1219 mm × 2438 mm weighs .

4. Corrosion Resistance & Causes of Rust

Stainless steel resists rust through its chromium oxide layer (≥10.5% Cr). However, corrosion may occur due to:

- Chloride exposure: Prolonged contact with seawater or de-icing salts can breach the passive layer, especially in 304L.

- Mechanical damage: Scratches or improper cleaning tools (e.g., steel wool) disrupt surface integrity.

- High-temperature oxidation: Continuous use above 425°C (797°F) degrades 304L’s corrosion resistance, whereas 316L withstands up to 450°C (842°F).

5. Eco-Friendly Manufacturing

Our plates are produced via argon-oxygen decarburization (AOD), reducing carbon emissions by 30% compared to traditional methods. Post-production processes include:

- Electropolishing: Enhances hygiene for non-toxic stainless steel kids plates by eliminating microscopic pores.

- Passivation: Boosts corrosion resistance using nitric acid baths.

Advanced Applications

- Name plate stainless steel: Laser-cut identification tags with <0.1 mm precision, resistant to UV and chemical fading.

- Non-toxic stainless steel kids plates: FDA-compliant surfaces for baby products and kitchenware.

- Oversized stainless steel wall plates: Seamless 3×6 m panels for architectural cladding, backed by a 20-year anti-corrosion warranty.

Why Choose Our Stainless Steel Plates?

- Superior Corrosion Resistance: 316L’s molybdenum content outperforms 304L in marine and industrial settings.

- Certified Safety: RoHS and REACH compliance ensures suitability for food, medical, and childcare applications.

- Custom Solutions: Tailored dimensions and finishes (e.g., brushed, perforated) for projects like oversized stainless steel wall plates.

- Global Standards: Dual-certified 304L/304 and 316L/316 grades meet ASTM, EN, and JIS specifications.

- Eco-Conscious: 30% recycled content and ISO 14001-certified production.